We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

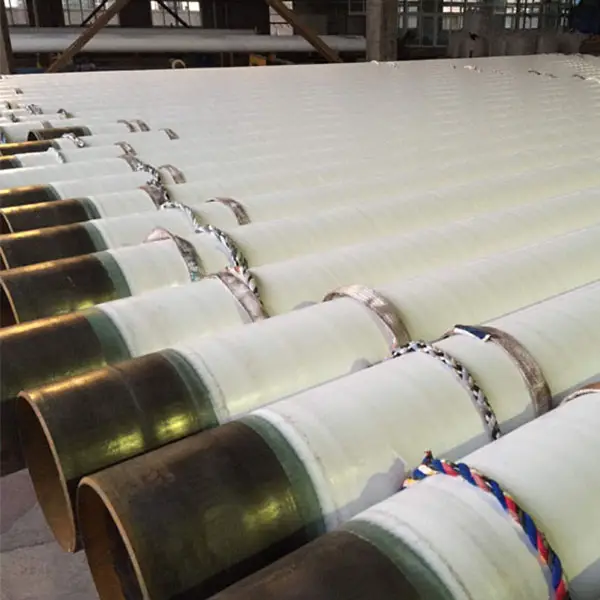

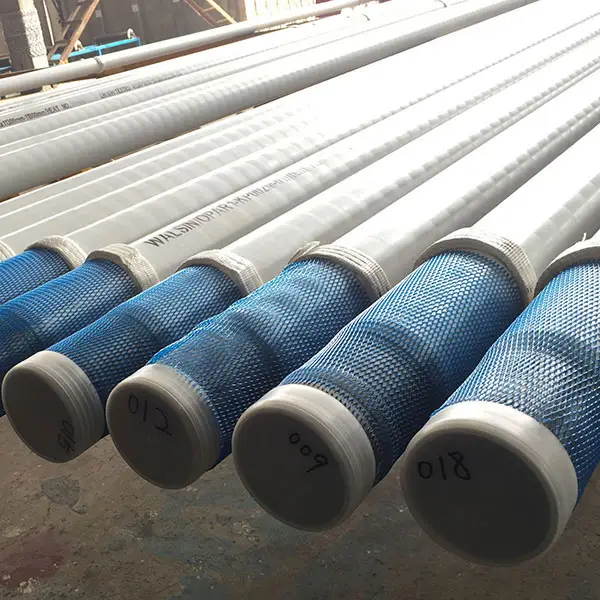

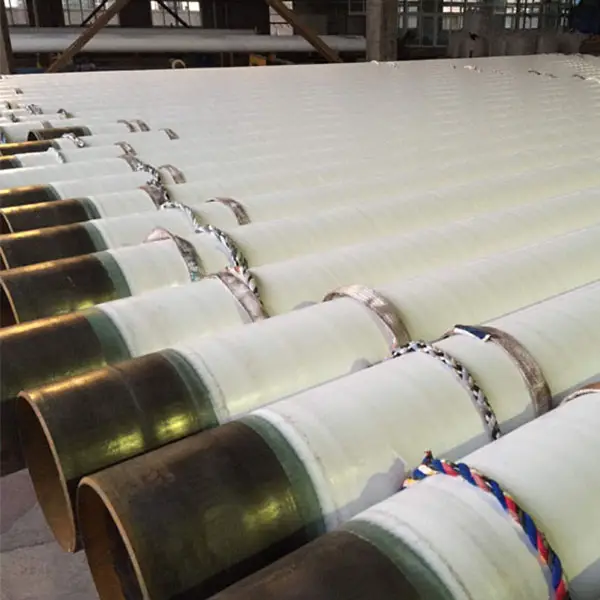

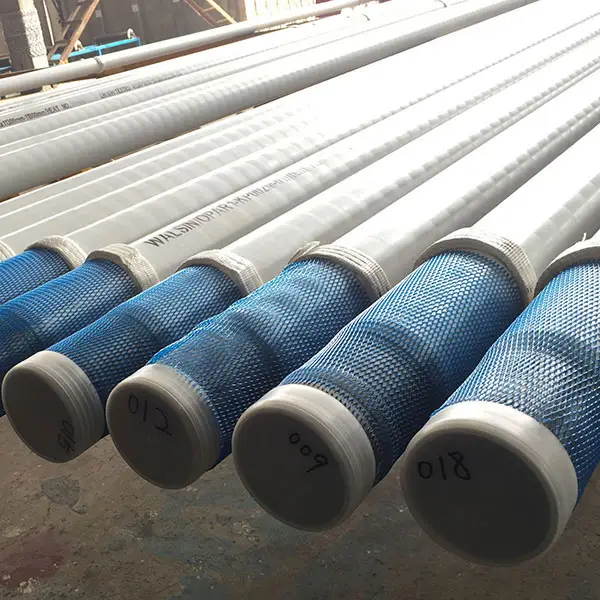

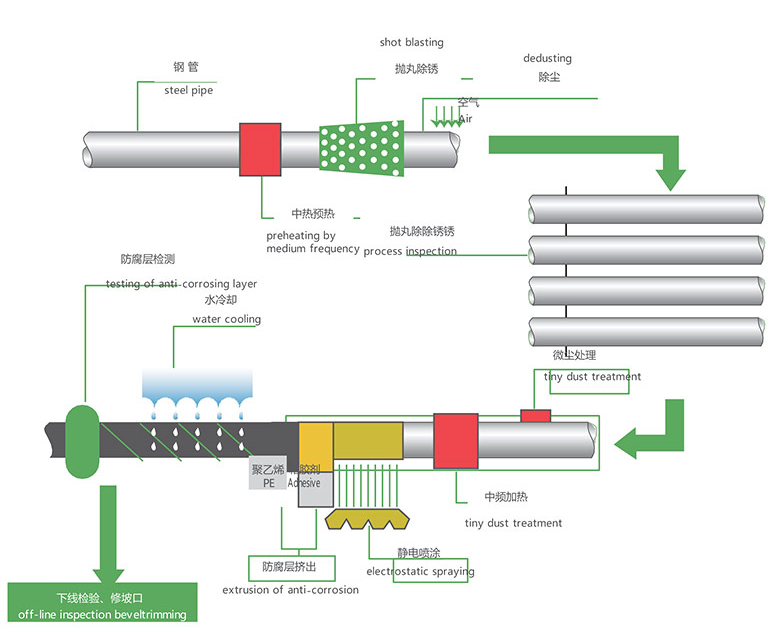

3LPP Pipe Coating is a three layer polypropylene coating technique that uses polypropylene as the coating material. There are three layers in this coating. The outer layer is the polypropylene in the 3lpp pipe coating and there is a middle layer made up of adhesives to bond the epoxy layer inside that is fusion bonded. This special structure protects the material from a number of conditions and materials. The 3lpp pipeline coating is excellent in preventing the steel pipes from being in contact with corrosive chemicals and agents. Also the coating prevents the material to come into contact with any hard surfaced directly and prevents physical damage as well.

The 3lpp coated pipe can come in different specifications such as DIN30678, CSA Z245.21-02, NF A49-711, ISO 9001:2008. The coating is also resistant to cathodic disbondment, meaning, thee coating is not affected by electric charge which can damage most other types of coatings. The 3lpp pipe can last longer and has higher performance compared to non – coated or other types of coatings. The application of this special coating is mostly in the oil fields which operate under high temperatures. The Three Layer Polypropylene Coated Pipe can be used in abrasion prone applications such as drilling operations and in rocky surface applications.

|

3LPP means |

3 Layer Polypropylene Coating |

|

Minimum Pipe Diameter |

3.5" / 90 mm |

|

Maximum Pipe Diameter |

48"+ / 1220 mm + |

|

Minimum Temperature Range |

-20°C |

|

Maximum Temperature Range |

110°C (buried service) |

|

Specification |

· DIN 30670 · CSA Z245.21 · AS 4321 · IS 3581 |

|

Standard |

DIN 30670/ AWWA C200/ AWWA C210/ AWWA C213/ CSAZ245 |

|

Layers under 3LPP coating |

· 1st Layer : Fusion Bonded Epoxy (FBE) · 2nd Layer: copolymer adhesive · 3rt Top Layer: polypropylene |

Steel pipe material for 3LPP Coating

|

3LPP Stainless steel pipe |

ASTM A312, ASTM A269 Grade 304/ 316 Stainless steel Pipe |

|

3LPP API 5L Pipeline |

· API 5L line pipe · 3LPP Coated API 5L Grade B · API 5L X42/ X52/ X65/ X80, PSL1/ PSL2 |

|

3LPP Carbon steel pipe |

· ASTM A53 pipe (Grade B) · 3LPP Coated ASTM A106 pipe (Grade B/C) · ASTM A252 pipe · ASTM A134 and A135 · ASTM A333 (Grade 3/6) |

|

3LPP Alloy steel pipe |

ASME SA 335 / ASTM A335 P1/ P5/ P9/ P11/ P22/ P91 |

|

3LPP Nickel Alloy pipes |

ASTM B161, ASTM B622, ASTM B444 |

|

3LPP CRA clad / lined pipes |

|

The minimum thickness of anti-corrosion layers of 3LPP and 3LPE anti-corrosion systems

|

Pipe OD |

The minimum thickness of anti-corrosion layers (mm) |

|||||

|

PP |

PE |

FBE |

Adhesives |

3LPP total thickness |

3LPE total thickness |

|

|

≤100 |

1.3 |

2.0 |

0.3 |

0.2 |

1.8 |

2.5 |

|

> 100 and ≤ 250 |

1.5 |

2.2 |

0.3 |

0.2 |

2.0 |

2.7 |

|

> 250 and < 500 |

1.7 |

2.4 |

0.3 |

0.2 |

2.2 |

2.9 |

|

≥ 500 and < 800 |

2.0 |

2.7 |

0.3 |

0.2 |

2.5 |

3.2 |

|

≥800 |

2.0 |

3.2 |

0.3 |

0.2 |

2.5 |

3.7 |

The working life of 3LPP anti-corrosion (DIN 30678)

|

Operating Temperature ℃ |

Expected the shortest working life ( year) |

|

23 |

50 |

|

60 |

50 |

|

80 |

30 |

|

90 |

15 |

|

100 |

8 |

|

When used at where the temperature is changed, the working life can be concluded as above. |

|

DIN 30678-2013 Polypropylene coatings on steel pipes and Fittings

ISO 21809-1:2011 Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems -- Part 1: Polyolefin coatings (3-layer PE and 3-layer PP)

NFA 49-711 External Coating with Three Polyproplene Layers Coating, Application by Extrusion

SHELL DEP 31.40.30.31-CSPC External Polyethylene and Polypropylene Coating for Line Pipe

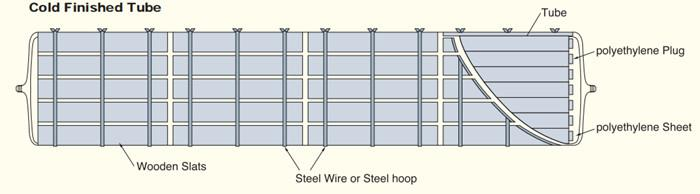

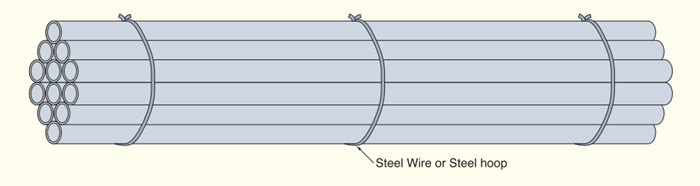

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.