We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

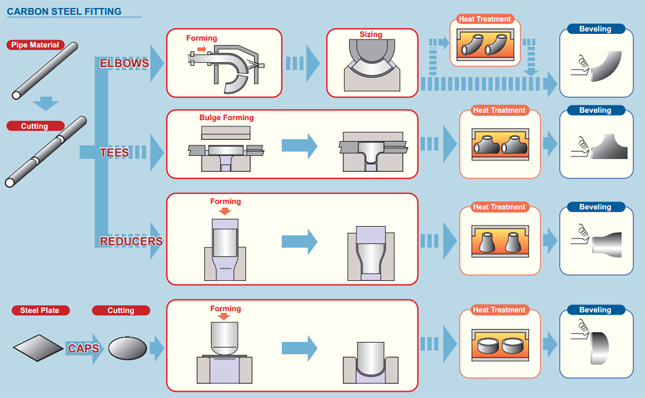

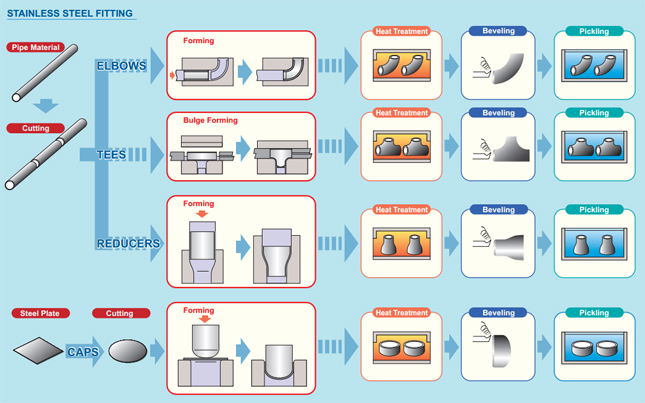

Pipe cap, a type of pipe fittings, usually covers the end of a tube, and it has the similar function with a plug. Our pipe caps are made of carbon steel, stainless steel and alloy steel, etc. They feature high strength, good toughness, and high resistance to corrosion, and vibration.

BW Steel Cap

BW steel pipe cap is the butt weld type of fittings, connecting methods is to use butt welding. So BW cap ends in beveled or plain.

Standard: ASTM A234, MSS SP-75, ASTM A403

Manufacturing Standard: ASME B16.9, DIN2615, JIS B2312

Size Range: 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48”. (DN15-DN1200)

Thickness: SCH 10, SCH 40, SCH 80

Black Painted, Varnished, Epoxy Coated, Galvanized

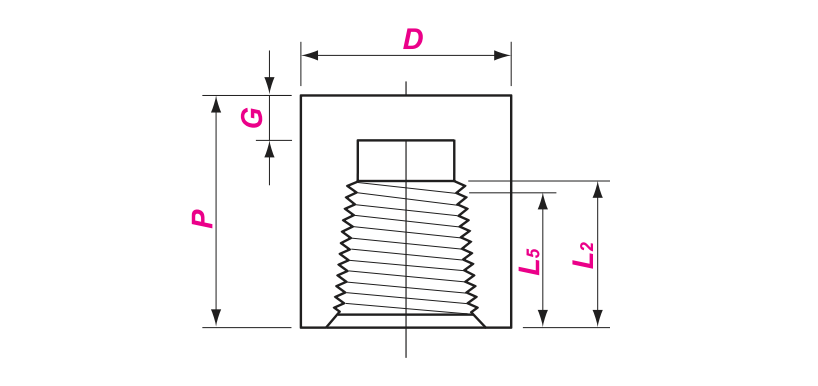

Socket Weld Steel Pipe Cap (and Threaded Cap)

Socket weld cap is to connecting pipes and caps by insert the pipe into the access shoulder area of the socket weld cap.

Standard: ASTM A105, ASTM A182

Manufacturing Standard: ASME B16.11

Dimensions: 1/2”, 1”, 1/2”, 2” and up to 4”

Pressure Ratings: 2000#, 3000#, 6000#, 9000#

Pipe Cap Material Grades

|

Stainless Steel Pipe Cap |

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

|

Carbon Steel Pipe Cap |

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

|

Low Temperature Carbon Steel Pipe Cap |

ASTM A420 WPL3, A420 WPL6 |

|

Alloy Steel Pipe Cap |

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

|

Duplex Pipe Cap |

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

|

Nickel Alloy Pipe Cap |

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

|

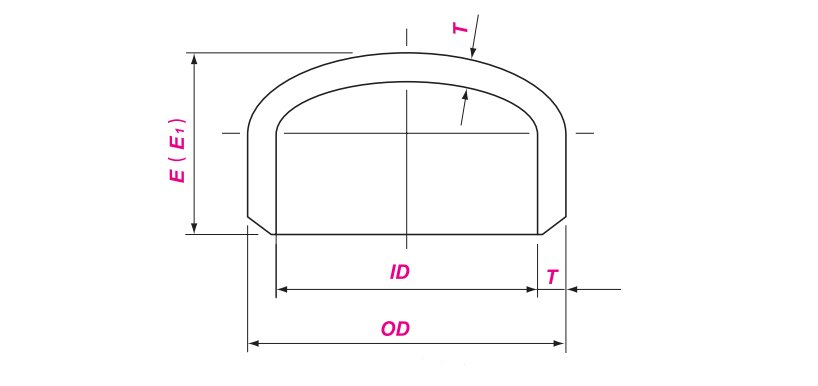

DN |

NPS |

OD |

E |

E1 |

|

15 |

1/2 |

21.3 |

25 |

25 |

|

20 |

3/4 |

26.7 |

25 |

25 |

|

25 |

1 |

33.4 |

38 |

38 |

|

32 |

1 1/4 |

42.2 |

38 |

38 |

|

40 |

1 1/2 |

48.3 |

38 |

38 |

|

50 |

2 |

60.3 |

38 |

44 |

|

65 |

2 1/2 |

73 |

38 |

51 |

|

80 |

3 |

88.9 |

51 |

64 |

|

90 |

3 1/2 |

101.6 |

64 |

76 |

|

100 |

4 |

114.3 |

64 |

76 |

|

125 |

5 |

141.3 |

76 |

89 |

|

150 |

6 |

168.3 |

89 |

102 |

|

200 |

8 |

219.1 |

102 |

127 |

|

250 |

10 |

273 |

127 |

152 |

|

300 |

12 |

323.9 |

152 |

178 |

|

350 |

14 |

355.6 |

165 |

191 |

|

400 |

16 |

406.4 |

178 |

203 |

|

450 |

18 |

457 |

203 |

229 |

|

500 |

20 |

508 |

229 |

254 |

|

550 |

22 |

558.8 |

254 |

254 |

|

600 |

24 |

609.6 |

267 |

305 |

|

650 |

26 |

660.4 |

267 |

– |

|

700 |

28 |

711.2 |

267 |

– |

|

750 |

30 |

762 |

267 |

– |

|

800 |

32 |

812.8 |

267 |

– |

|

850 |

34 |

863.6 |

267 |

– |

|

900 |

36 |

914.4 |

267 |

– |

|

950 |

38 |

965.2 |

305 |

– |

|

1000 |

40 |

1016 |

305 |

– |

|

1050 |

42 |

1066.8 |

305 |

– |

|

1100 |

44 |

1117.8 |

343 |

– |

|

1150 |

46 |

1168.4 |

343 |

– |

|

1200 |

48 |

1219.2 |

343 |

– |

|

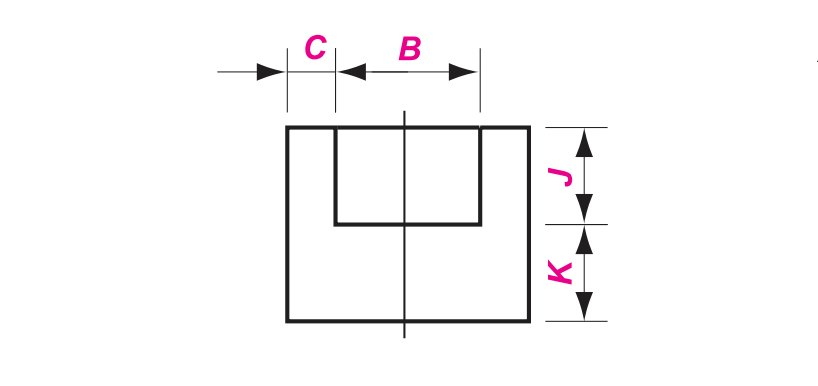

DN |

NPS |

B |

C |

J |

K |

|||||||

|

3000 |

6000 |

9000 |

3000 |

6000 |

9000 |

|||||||

|

ave |

min |

ave |

min |

ave |

min |

|||||||

|

6 |

1/8 |

10.9 |

3.18 |

3.18 |

3.96 |

3.43 |

|

|

9.5 |

4.8 |

6.4 |

|

|

8 |

1/4 |

14.3 |

3.78 |

3.3 |

4.6 |

4.01 |

|

|

9.5 |

4.8 |

6.4 |

|

|

10 |

3/8 |

17.7 |

4.01 |

3.5 |

5.03 |

4.37 |

|

|

9.5 |

4.8 |

6.4 |

|

|

15 |

1/2 |

21.9 |

4.67 |

4.09 |

5.97 |

5.18 |

9.53 |

8.18 |

9.5 |

6.4 |

7.9 |

11.2 |

|

20 |

3/4 |

27.3 |

4.9 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

12.5 |

6.4 |

7.9 |

12.7 |

|

25 |

1 |

34 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

12.5 |

9.6 |

11.2 |

14.2 |

|

32 |

1 1/4 |

42.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

12.5 |

9.6 |

11.2 |

14.2 |

|

40 |

1 1/2 |

48.9 |

6.35 |

5.54 |

8.92 |

7.8 |

12.7 |

11.12 |

12.5 |

11.2 |

12.7 |

15.7 |

|

50 |

2 |

61.2 |

6.93 |

6.04 |

10.92 |

9.5 |

13.84 |

12.12 |

16 |

12.7 |

15.7 |

19 |

|

65 |

2 1/2 |

73.9 |

8.76 |

7.62 |

|

|

|

|

16 |

15.7 |

19 |

|

|

80 |

3 |

89.9 |

9.52 |

8.3 |

|

|

|

|

16 |

19 |

22.4 |

|

|

100 |

4 |

115.5 |

10.69 |

9.35 |

|

|

|

|

19 |

22.4 |

28.4 |

|

|

DN |

NPS |

P |

D |

G |

L5 |

L2 |

|||

|

3000 |

6000 |

3000 |

6000 |

3000 |

6000 |

||||

|

6 |

1/8 |

19 |

– |

16 |

22 |

4.8 |

– |

6.4 |

6.7 |

|

8 |

1/4 |

25 |

27 |

19 |

25 |

4.8 |

6.4 |

8.1 |

10.2 |

|

10 |

3/8 |

25 |

27 |

22 |

32 |

4.8 |

6.4 |

9.1 |

10.4 |

|

15 |

1/2 |

32 |

33 |

28 |

38 |

6.4 |

7.9 |

10.9 |

13.6 |

|

20 |

3/4 |

37 |

38 |

35 |

44 |

6.4 |

7.9 |

12.7 |

13.9 |

|

25 |

1 |

41 |

43 |

44 |

57 |

9.7 |

11.2 |

14.7 |

17.3 |

|

32 |

1 1/4 |

44 |

46 |

57 |

64 |

9.7 |

11.2 |

17 |

18 |

|

40 |

1 1/2 |

44 |

48 |

64 |

76 |

11.2 |

12.7 |

17.8 |

18.4 |

|

50 |

2 |

48 |

51 |

76 |

92 |

12.7 |

15.7 |

19 |

19.2 |

|

65 |

2 1/2 |

60 |

64 |

92 |

108 |

15.7 |

19 |

23.6 |

28.9 |

|

80 |

3 |

65 |

68 |

108 |

127 |

19 |

22.4 |

25.9 |

30.5 |

|

100 |

4 |

68 |

75 |

140 |

159 |

22.4 |

28.4 |

27.7 |

33 |

|

ASTM A234 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

|

ASTM A420 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

|

ASTM A403 |

Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

|

ASME B16.9 |

Factory Made Wroght Steel Butt Welding Fittings |