We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

Specialty Pipe Piling and Piles

Pipe piles are one of the most versatile pile found in the deep foundation industry. As such, there are several types of pipe piles that should be considered based on the application. These include:

Standard Steel Piles: Load bearing piles that support a large range of different pile types. Various attachments, including conical points, can be welded to the pile for more efficient driving through specific soil types

Micro Piles: Ideal for projects with minimal workspace and low headroom. In a mini caisson, the pile is filled with concrete to help reduce high underground pressures and reinforced with high strength rebar

Helical piles or Screw Piles: These piles have a screw or helix welded to the end of the pile shaft. The pile is then “screwed” into the ground for deep foundation projects. This leads to an ease of installation, shorter project times and less soil displacement than other pile types.

Usage: Used for low pressure liquid delivery, such as water, gas, and oil; construction and piling

Standard: API 5L, API 5CT, ASTM A252, ASTM 53, EN10217, EN10219, BS 5950, ASTM A572 , JIS, IS,

Certificate: EN10217, EN10219, API 5L PSL1/ PSL2, API 5CT

Size:Out Diameter: 219.1mm –3048mm

Wall Thickness: 5.0mm-30mm

Length: Up to 70m

Steel Grade:

API 5L: GR A, GR B, X42,X46, X56, X60,X65,X70

ASTM A252 GR 1, GR 2, GR 3

ASTM A53: GR A, GR B, GR C, GR D

BS 4360: Grade 43, Grade 50

EN: S275, S275JR, S355JRH, S355J2H

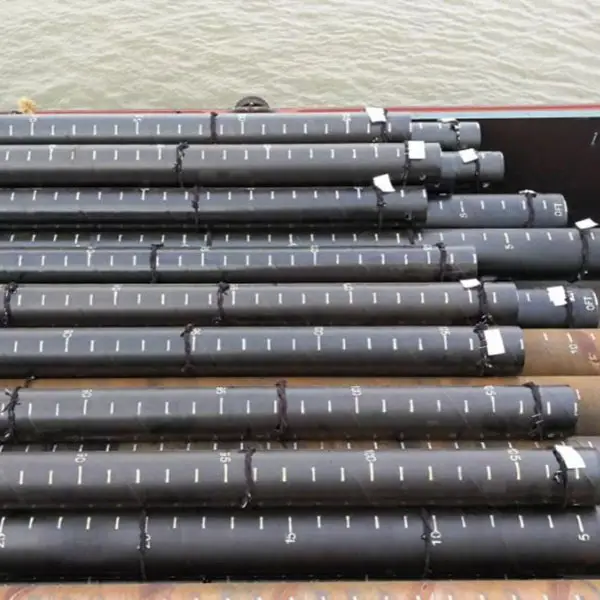

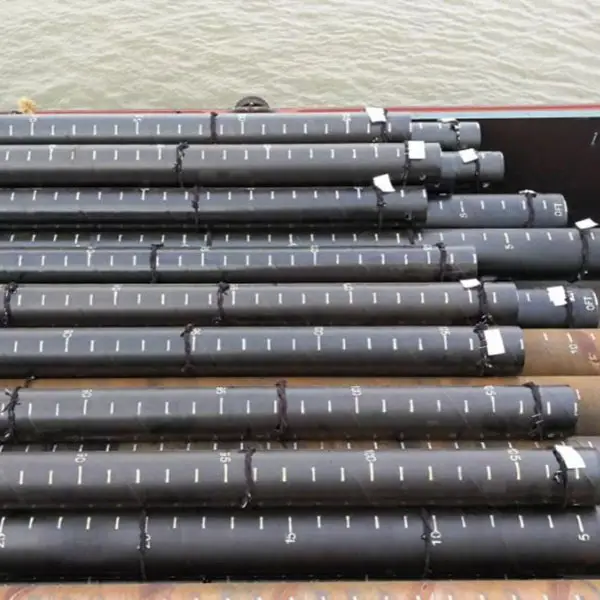

Surface: Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204/3.1B

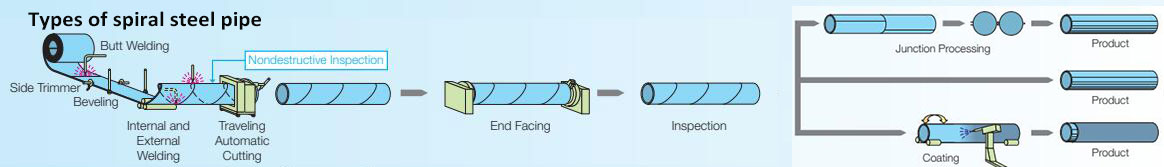

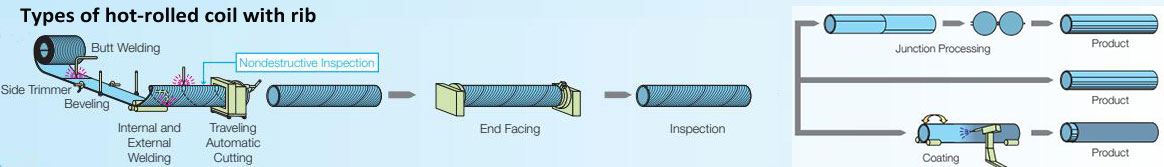

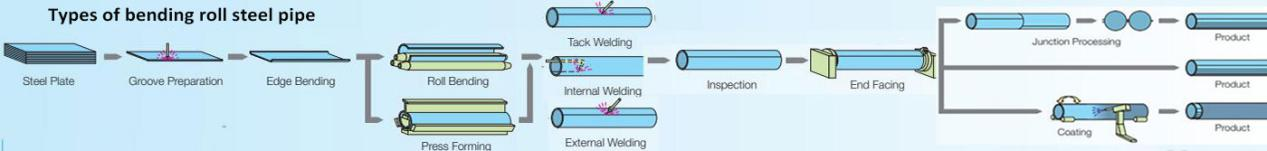

The widely used forms of pile pipe: Usually in big diameters (heavy-duty steel pipe), dimensions from 16 inch up to 60 inch, manufactured using seamless, longitudinal welded (LSAW), or spiral welded(SSAW). Depends on the soil environments, pipe could be coated with zinc (galvanized), FBE or 3PE coated. In this way to provide moisture resistance and corrosion resistance.

Applications

Steel pipe pile is a most recommend piling material for sea port constructions, yard buildings. It has been widely used in sea works or marine works, to create the tough foundations. Other than this, typical uses also as under buildings, bridges, and structural constructions. More details uses as below list:

Onshore and offshore constructions

Marine foundations / constructions

Tower building

Railway, highway construction

Dock yard construction

Sea works, marine works

Oil and gas filed fundations

Structural support in special buildings

and etcs.

|

ERW |

Wall Thickness (inches) |

|||||||||

|

Outside Diameter (inches) |

lbs / ft |

0.188 |

0.219 |

0.250 |

0.312 |

0.375 |

0.438 |

0.500 |

0.625 |

0.750 |

|

8.625 |

16.96 |

19.68 |

22.38 |

27.73 |

33.07 |

38.33 |

43.43 |

|

|

|

|

10.75 |

21.23 |

24.65 |

28.06 |

34.81 |

41.59 |

48.28 |

54.79 |

|

|

|

|

12.75 |

25.25 |

29.34 |

33.41 |

41.48 |

49.61 |

57.65 |

65.48 |

|

|

|

|

14 |

27.76 |

32.26 |

36.75 |

45.65 |

54.62 |

63.50 |

72.16 |

|

|

|

|

16 |

31.78 |

36.95 |

42.09 |

52.32 |

62.64 |

72.86 |

82.85 |

102.72 |

|

|

|

18 |

|

41.63 |

47.44 |

58.99 |

70.65 |

82.23 |

93.54 |

116.09 |

|

|

|

20 |

|

|

52.78 |

65.66 |

78.67 |

91.59 |

104.23 |

129.45 |

|

|

|

24 |

|

|

63.47 |

79.01 |

94.71 |

110.32 |

125.61 |

156.17 |

186.41 |

|

|

DSAW |

Wall Thickness (inches) |

|||||||

|

Outside Diameter (inches) |

lbs / ft |

0.312 |

0.375 |

0.500 |

0.625 |

0.750 |

0.875 |

1.000 |

|

24 |

79.01 |

94.71 |

125.61 |

156.17 |

186.41 |

|

|

|

|

26 |

85.68 |

102.72 |

136.3 |

139.54 |

202.44 |

|

|

|

|

28 |

92.35 |

110.74 |

146.99 |

182.9 |

218.48 |

253.72 |

|

|

|

30 |

99.02 |

118.76 |

157.68 |

196.26 |

234.51 |

272.43 |

|

|

|

32 |

105.69 |

126.78 |

168.37 |

209.62 |

250.55 |

291.14 |

|

|

|

34 |

112.36 |

134.79 |

179.06 |

222.99 |

266.58 |

309.84 |

|

|

|

36 |

|

142.81 |

189.75 |

236.35 |

282.62 |

328.55 |

|

|

|

38 |

|

150.83 |

200.44 |

249.71 |

298.65 |

347.26 |

|

|

|

40 |

|

158.85 |

211.13 |

263.07 |

314.69 |

365.97 |

|

|

|

42 |

|

166.86 |

211.82 |

276.44 |

330.72 |

384.67 |

438.29 |

|

|

44 |

|

174.88 |

232.51 |

289.8 |

346.76 |

403.38 |

459.67 |

|

|

46 |

|

182.9 |

243.2 |

303.16 |

362.79 |

422.09 |

481.05 |

|

|

48 |

|

190.92 |

253.89 |

316.52 |

378.83 |

440.8 |

502.43 |

|

|

Spiral Weld |

Wall Thickness (inches) |

|||||||||

|

Outside Diameter (inches) |

lbs / ft |

0.250 |

0.312 |

0.375 |

0.438 |

0.500 |

0.625 |

0.750 |

0.875 |

1.000 |

|

18 |

47.4 |

59 |

70.7 |

82.2 |

93.5 |

|

|

|

|

|

|

20 |

52.8 |

65.7 |

78.7 |

91.6 |

104.2 |

|

|

|

|

|

|

22 |

58.1 |

72.3 |

86.7 |

101 |

114.9 |

142.8 |

|

|

|

|

|

24 |

63.5 |

79 |

94.7 |

110.3 |

125.6 |

156.2 |

186.4 |

|

|

|

|

26 |

68.8 |

85.7 |

102.7 |

119.7 |

136.3 |

169.5 |

202.4 |

|

|

|

|

28 |

74.2 |

92.4 |

110.7 |

129.1 |

147 |

182.9 |

218.5 |

|

|

|

|

30 |

79.5 |

99 |

118.8 |

138.4 |

157.7 |

196.3 |

234.5 |

272.4 |

|

|

|

32 |

84.9 |

105.7 |

126.8 |

147.8 |

168.4 |

209.6 |

250.5 |

291.1 |

|

|

|

34 |

90.2 |

112.4 |

134.8 |

157.1 |

179.1 |

223 |

266.6 |

309.8 |

|

|

|

36 |

95.5 |

119 |

142.8 |

166.5 |

189.7 |

236.3 |

282.6 |

328.6 |

374.2 |

|

|

38 |

100.9 |

125.7 |

150.8 |

175.9 |

200.4 |

249.7 |

298.7 |

347.3 |

395.5 |

|

|

40 |

106.2 |

132.4 |

158.8 |

185.2 |

211.1 |

263.1 |

314.7 |

366 |

416.9 |

|

|

42 |

111.6 |

139 |

166.9 |

194.6 |

221.8 |

276.4 |

330.7 |

384.7 |

438.3 |

|

|

48 |

127.6 |

159.1 |

190.9 |

222.7 |

253.9 |

316.5 |

378.8 |

440.8 |

502.4 |

|

|

54 |

|

179.1 |

215 |

250.8 |

286 |

356.6 |

426.9 |

496.9 |

566.6 |

|

|

60 |

|

199.1 |

239 |

278.9 |

318 |

396.7 |

475 |

553 |

630.7 |

|

|

66 |

|

219.1 |

263.1 |

307 |

350.1 |

436.8 |

523.1 |

609.2 |

694.9 |

|

|

72 |

|

239.1 |

287.1 |

335.1 |

382.2 |

476.9 |

571.2 |

665.3 |

759 |

|

|

78 |

|

259.1 |

311.2 |

363.2 |

414.2 |

517 |

649.4 |

721.4 |

823.1 |

|

|

84 |

|

279.1 |

335.2 |

391.3 |

446.3 |

557 |

667.5 |

777.5 |

887.3 |

|

|

90 |

|

229.1 |

359.3 |

419.3 |

478.4 |

597.1 |

715.6 |

833.7 |

951.4 |

|

|

96 |

|

319.1 |

383.3 |

447.4 |

510.4 |

637.2 |

763.7 |

889.8 |

1015.6 |

|

ASTM A252--This specification is generally for the wall steel pipes that are cylindrical in shape and the steel cylinder acts like a load-carrying member for the cast-in-place piles of concrete.Grades in three levels, Gr 1, Gr 2, and Gr 3.

STEEL CHEMICAL COMPOSITION

The steel shall conform to the following requirements as to chemical composition:

Phosphorus, maximum (%) : 0.050

MECHANICAL PROPERTIES

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

|

GRADE 1 |

30,000 (205) |

50,000 (345) |

30% |

|

GRADE 2 |

35,000 (240) |

60,000 (415) |

25% |

|

GRADE 3 |

45,000 (310) |

66,000 (455) |

20% |

TEST REQUIRED

Chemical Analysis, Mechanical Test, Visusal Inspection , Tension Test, Dimension Check

EN10219 Structure Pipe

STEEL GRADE

EN10219 S235, S275, S355,etc

STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

% by mass, Maximum |

|||||

|

C |

Si |

Mn |

P |

S |

N |

|

|

S235JRH |

0.17 |

– |

1.40 |

0.040 |

0.040 |

0.009 |

|

S275JOH |

0.20 |

– |

1.50 |

0.035 |

0.035 |

0.009 |

|

S275J2H |

0.20 |

– |

1.50 |

0.030 |

0.030 |

– |

|

S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

0.009 |

|

S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

– |

|

S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

– |

MECHANICAL PROPERTIES

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

Minimum Impact energy KV J |

||

|

at test temperature of |

||||||

|

-20 |

0 |

20 |

||||

|

S235JRH |

235 |

360 |

24% |

– |

– |

27 |

|

S275JOH |

275 |

430 |

20% |

– |

27 |

– |

|

S275J2H |

355 |

510 |

20% |

27 |

– |

– |

|

S355JOH |

355 |

510 |

20% |

– |

27 |

– |

|

S355J2H |

355 |

510 |

20% |

27 |

– |

– |

|

S355K2H |

355 |

510 |

20% |

40 |

– |

– |

TEST REQUIRED

Chemical Analysis, Mechanical Test, Visusal Inspection , Tensile Test, Dimension Check, NDT ,Impact Test

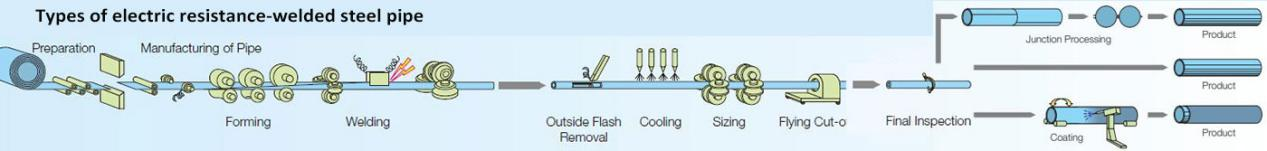

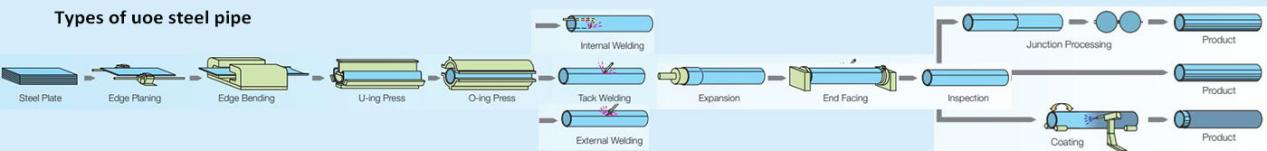

Pipe piling generally manufactured using seamless, resistance welding, fusion welding, flash welding with seams being longitudinal, helical. It also specifies the tensile requirements, minimum values and the common size and weight based on the values.