We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

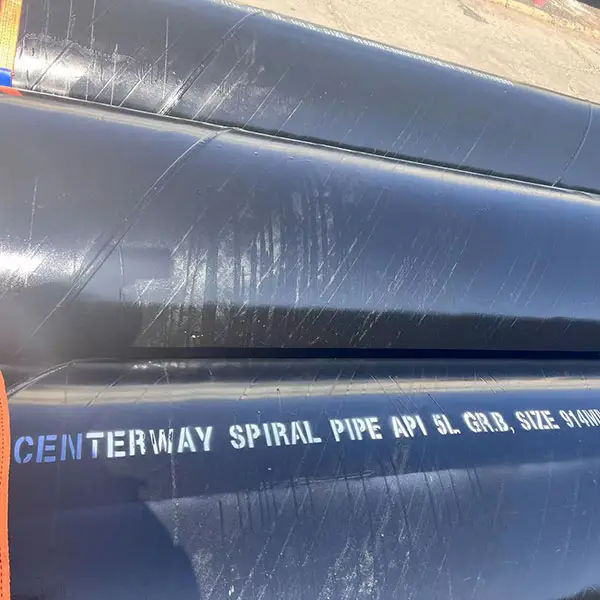

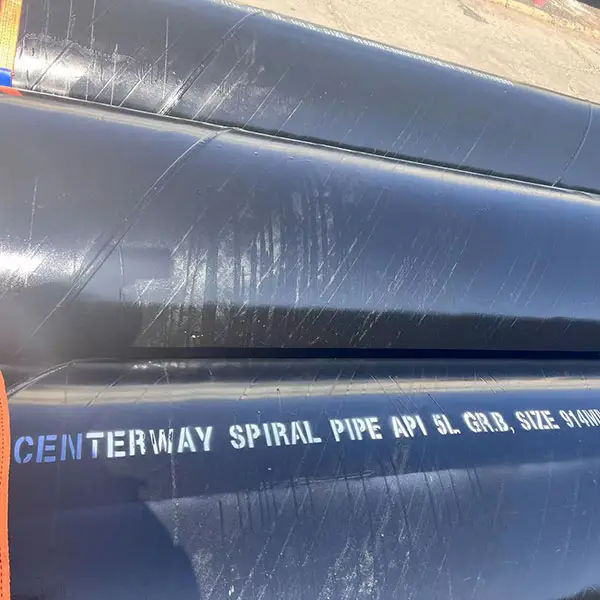

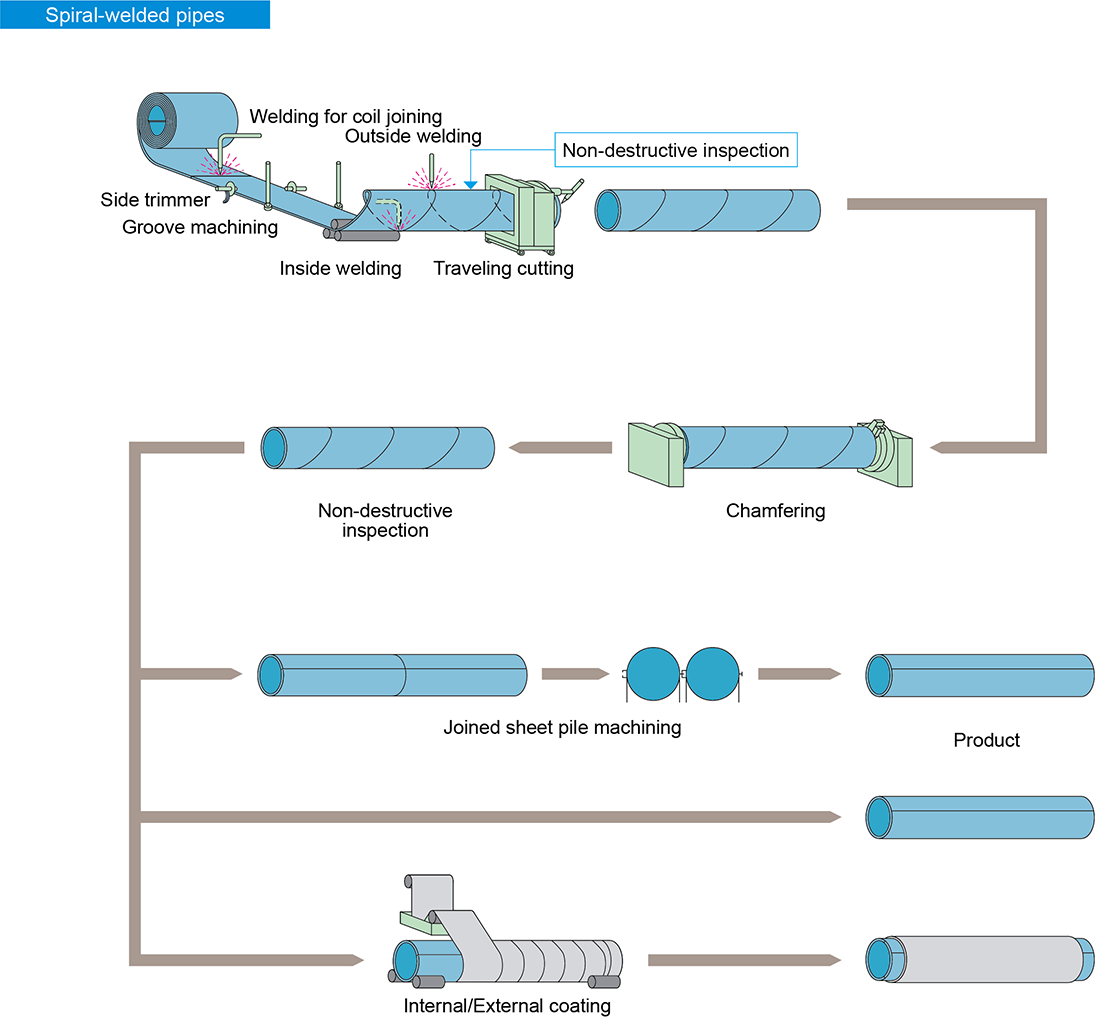

SSAW steel pipe, also known as spiral submerged arc welded steel pipe, is a spiral welded steel pipe produced by double-sided submerged arc welding. Spiral welded pipes are formed using narrower sheets or hot rolled coils, which greatly reduces their production costs. The spiral welding process allows the production of large diameter pipes suitable for transporting large quantities of oil and gas.

Sizes:

Out diameter:219mm-3620mm

Wall thickness: 5mm-25.4mm

Length: 3m-12m

|

Classfication |

Standard |

Main Products |

|

Steel Pipe for Fluid Service |

GB/T 14291 |

Welded pipe for mine fluid sevice |

|

GB/T 3091 |

Welded pipe for low pressure fluid service |

|

|

SY/T 5037 |

Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service |

|

|

ASTM A53 |

Black and hot-hipped galvanized welded and seamless steel pipe |

|

|

BS EN10217-2 |

Welded steel tybes for pressure purposes - delivery technical conditions - part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties |

|

|

BS EN10217-5 |

Welded steel tybes for pressure purposes - delivery technical conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties |

|

|

Steel Pipe for Ordinary Structure |

GB/T 13793 |

Longitudinally electric resistance welded steel pipe |

|

SY/T 5040 |

Spirally submerged arc welded steel pipe piles |

|

|

ASTM A252 |

Welded and seamless steel pipe piles |

|

|

BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivert conditions |

|

|

BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties |

|

|

Line Pipe |

GB/T 9711.1 |

Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

|

GB/T 9711.2 |

Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) |

|

|

API 5L PSL1/2 |

Line pipe |

|

|

Casing |

API 5CT |

Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

|

Out Diameter |

Wall Thickness (mm) |

||||||||||||||||||||

|

mm |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

|

|

219.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

273 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

323.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

325 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

355.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

377 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

426 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

478 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

529 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

630 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

720 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

820 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

920 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1020 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1420 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1620 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1820 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2020 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2540 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A53 |

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

API 5L |

Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

|

A252 |

Standard Specification for Welded and Seamless Steel Pipe Piles |

|

A500 |

Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

|

BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivert conditions |

|

BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties |

Chemical Analysis and Mechanical Properties

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Si |

Mn |

P |

S |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

||

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

|

B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

|

|

X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

|

|

X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

|

|

X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

|

|

X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

|

|

X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

|

|

X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

|

|

X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

|

|

API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

|

X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

|

|

X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

|

|

X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

|

|

X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

|

|

X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

|

|

X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

|

|

X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

|

|

X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

|

|

ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

|

B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

|

|

ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

|

2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

|

|

3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

|

|

EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

|

P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

|

S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

|

|

S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

|

|

S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

|

|

S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

|

S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

Spiral steel pipe (SSAW) is a spiral seam steel pipe made of strip steel coils as raw materials, often extruded and formed by automatic double-wire double-sided submerged arc welding. The spiral steel pipe feeds the strip steel into the welded pipe unit. After rolling by multiple rollers, the strip steel is gradually rolled up to form a round tube blank with an open gap. The reduction of the squeeze roller is adjusted to control the weld gap at 1~ 3mm, and make both ends of the welding joint flush.

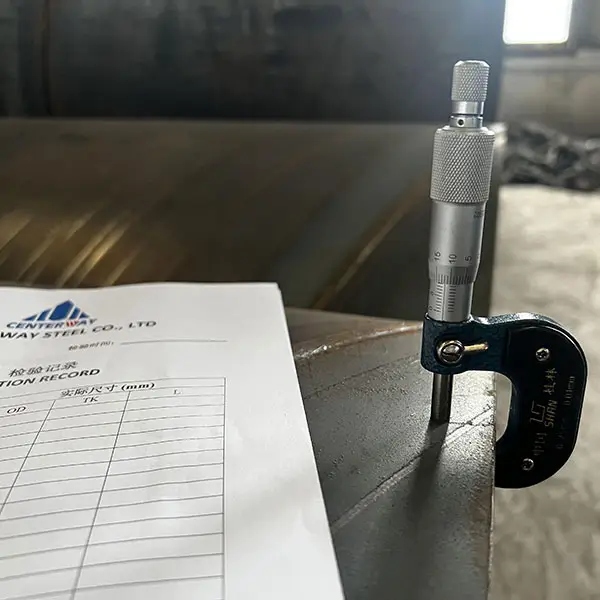

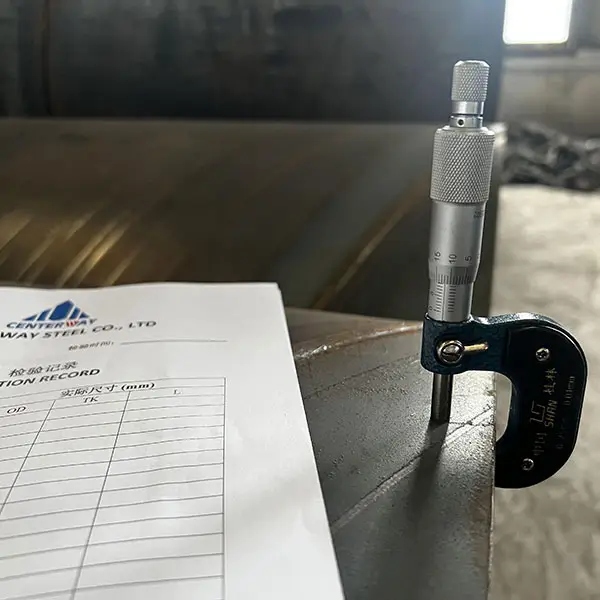

In bundle, black, caps, beveled ends or plain ends2.OEM/ customer's REQUEST3.Marks: Standard * Material*OD*WT*L *Heat No./required Shipping:a. Length: ≤5.85m, loaded in 20FT Container, Max 25tonsb. Length: ≤12m, loaded in 40 FT Container, Max 26.5tonsc. Length: >12m, shipped by bulk vessel. Delivery time :about 10-30 days after received deposit