We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

About Tubing coupling

Normally tubing coupling OD maximum is 4 1/2”, as the tubing pipe is applied for the drilling activities (Inside the tubing is the sucker rod to drill/pump the oil), couplings type is more various and rigorous than casing, mostly used is thicken type upset coupling (Internal upset and external upset), for short is EUE coupling, it is the most favorable in tubing connections. Tubing with EU end (EUE) coupling connection also called UPTBG. Because of the end of the tubing is thickened (upset), the connecting stress is better than buttress coupling.

Buttress coupling another type used for tubing connections, it has the same thickness of the pipe body, called NU end (NUE)tubing or TBG.

Features

The oil tubing coupling can solve the problem of fatigue fracture in the existing coupling due to stress concentration. Oil tubing end is connected to the inside wall of the coupling in a tapered thread. The coupling body end and oil tubing are connected with same thread pitch flat thread. The coupling is not easy to produce fatigue fracture, and has good connection effect. It can prevent the accident of oil well pipe string break effectively.

About Casing coupling

Casing coupling is for the dimensions more than 4 1/2 inch. Differently than tubing coupling is, casing coupling normally does not need to be thickened (Non-upset), which means no upset casing coupling, so it has following types:

• BTC: Buttress coupling

• LTC: Long buttress coupling

• STC: Short buttress coupling

All three types has same thickness of the casing pipe body, just have different lengths.

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

Seamless and ERW Casing

|

Specification |

API 5CT |

|

Grades |

K55, N80, L80, C95, P110, Chrome, J55(Modified), J55 (API), PS80 |

|

Special Grades |

For sour services and for deep well with high collapse properties |

|

Dimensions |

OD 4" - 26" WT - 0.2 -0.5" |

|

Length range |

1, 2 or 3 |

|

Thread connections |

API (STC and LTC), BTC, extreme line, etc. |

Seamless and ERW Tubing

|

Specification |

API 5CT |

|

Grades |

J55 (API) J55(Modified), N80, L80, L80 13Cr, P110, Q125, H40 (API) |

|

Thread connections |

API 5B - Last Edition or Premium, EUE, NUE, special seal, metal-to-metal seal and VAGT |

Casing Couplings Short Thread Specifications:

|

Casing Couplings |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

4-1/2 |

5.000 |

6.250 |

8.05 |

343 |

2716 |

|

5 |

5.563 |

6.500 |

10.18 |

210 |

2168 |

|

|

5-1/2 |

6.050 |

6.750 |

11.44 |

216 |

2501 |

|

|

6-5/8 |

7.390 |

7.250 |

19.97 |

115 |

2322 |

|

|

7 |

7.656 |

7.250 |

18.34 |

120 |

2231 |

|

|

7-5/8 |

8.500 |

7.500 |

26.93 |

80 |

2322 |

|

|

8-5/8 |

9.625 |

7.750 |

35.58 |

60 |

2132 |

|

|

9-5/8 |

10.625 |

7.750 |

39.51 |

50 |

2006 |

|

|

10-3/4 |

11.750 |

8.000 |

49.61 |

45 |

2079 |

|

|

11-3/4 |

12.750 |

8.000 |

50.49 |

35 |

1767 |

|

|

13-3/8 |

14.375 |

8.000 |

56.23 |

25 |

1436 |

|

|

16 |

17.000 |

9.000 |

78.98 |

20 |

- |

|

|

18-5/8 |

20 |

9.000 |

118.94 |

10 |

- |

|

|

20 |

21.000 |

9.000 |

98.25 |

10 |

- |

Casing Couplings Long Thread Specifications

|

Casing Couplings |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

4-1/2 |

5.000 |

7.000 |

9.07 |

294 |

2697 |

|

5 |

5.563 |

7.750 |

12.56 |

210 |

2573 |

|

|

5-1/2 |

6.050 |

8.000 |

14.03 |

180 |

2555 |

|

|

6-5/8 |

7.390 |

8.750 |

24.82 |

100 |

2315 |

|

|

7 |

7.656 |

9.000 |

23.67 |

100 |

2351 |

|

|

7-5/8 |

8.500 |

9.250 |

34.23 |

80 |

2807 |

|

|

8-5/8 |

9.625 |

10.000 |

47.48 |

48 |

2337 |

|

|

9-5/8 |

10.625 |

10.500 |

55.77 |

40 |

2302 |

|

|

10-3/4 |

11.750 |

* 10.500 |

* 62.38 |

45 |

* 36 |

|

|

11-3/4 |

12.750 |

* 10.500 |

* 67.59 |

30 |

* 24 |

|

|

13-3/8 |

14.375 |

* 10.500 |

* 76.63 |

25 |

* 20 |

|

|

16 |

17.000 |

* 11.000 |

* 96.55 |

20 |

* 16 |

|

|

18-5/8 |

20.000 |

- |

- |

10 |

8 |

|

|

20 |

21.000 |

* 11.500 |

* 126.74 |

10 |

8 |

|

|

* NOT API SPECIFICATIONS. |

||||||

Casing Coupling - Buttress Thread

|

Casing Couplings |

Casing Size OD (inches) |

Coupling Size OD(inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

4-1/2 |

5.000 |

8.875 |

10.11 |

196 |

2007 |

|

5 |

5.563 |

9.125 |

12.99 |

144 |

2840 |

|

|

5-1/2 |

6.050 |

9.250 |

14.14 |

144 |

2061 |

|

|

6-5/8 |

7.390 |

9.625 |

24.46 |

92 |

2295 |

|

|

7 |

7.656 |

10.000 |

23.22 |

80 |

2068 |

|

|

7-5/8 |

8.500 |

10.375 |

64.84 |

64 |

2221 |

|

|

8-5/8 |

9.625 |

10.625 |

45.94 |

48 |

2414 |

|

|

9-5/8 |

10.625 |

10.625 |

50.99 |

40 |

2256 |

|

|

10-3/4 |

11.750 |

10.625 |

56.68 |

36 |

2307 |

|

|

11-3/4 |

12.750 |

10.625 |

61.74 |

24 |

2179 |

|

|

13-3/8 |

14.375 |

10.625 |

69.95 |

20 |

1429 |

|

|

16 |

17.000 |

10.625 |

87.56 |

16 |

- |

|

|

18-5/8 |

20.000 |

10.625 |

138.03 |

8 |

- |

|

|

20 |

21.000 |

10.625 |

110.33 |

8 |

- |

|

EUE |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Threads per inch |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

1.90 |

2.500 |

10 Round |

- |

1.85 |

- |

- |

|

2-3/8 |

3.063 |

8 Round |

4.875 |

3.42 |

1,444 |

3942 |

|

|

2-7/8 |

3.668 |

8 Round |

5.500 |

5.29 |

792 |

4220 |

|

|

3-1/2 |

4.500 |

8 Round |

5.750 |

9.02 |

448 |

3860 |

|

|

4 |

5.000 |

8 Round |

- |

10.62 |

392 |

- |

|

|

4-1/2 |

5.563 |

8 Round |

6.500 |

13.31 |

252 |

3456 |

|

Non-Upset |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Threads per inch |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

1.90 |

2.200 |

10 Round |

3.750 |

1.85 |

- |

- |

|

2-3/8 |

2.875 |

10 Round |

4.500 |

2.82 |

1,512 |

4264 |

|

|

2-7/8 |

3.500 |

10 Round |

5.500 |

5.15 |

800 |

4120 |

|

|

3-1/2 |

4.250 |

10 Round |

5.625 |

8.17 |

502 |

4101 |

|

|

4 |

4.75 |

8 Round |

5.75 |

9.57 |

392 |

- |

|

|

4-1/2 |

5.200 |

8 Round |

6.500 |

10.76 |

252 |

2712 |

Coupling Pipe Grade Identification By Paint Color

|

Coupling colour code |

|||||

|

Grade |

Grade Type |

Colour(s) for Coupling |

Number andcolour of bands for product |

Picture |

|

|

EntireCoupling |

Band(s) |

||||

|

H40 |

|

None |

Same as for pipe |

None/black band at the manufacturer’s option |

|

|

J55 Tubing |

|

Bright Green |

None |

One Bright Green |

|

|

J55 Casing |

|

Bright Green |

One White |

One Bright Green |

|

|

K55 |

|

Bright Green |

None |

Two Bright Green |

|

|

M65 |

|

M65Pipe uses L80Type 1Couplings |

One Bright GreenOne Blue |

|

|

|

N80 |

1 |

Red |

None |

One Red |

|

|

N80 |

Q |

Red |

One Green |

One RedOne Bright Green |

|

|

R95 |

|

Brown |

None |

One Brown |

|

|

L80 |

1 |

Red |

One Brown |

One RedOne Brown |

|

|

L80 |

9Cr |

None |

Two Yellow |

One Red,One Brown, Two Yellow |

|

|

L80 |

13Cr |

None |

One Yellow |

One Red,One Brown, One Yellow |

|

|

C90 |

1 |

Purple |

None |

One Purple |

|

|

T95 |

1 |

Silver |

None |

One Silver |

|

|

C110 |

|

White |

Two Brown |

One White,Two Brown |

|

|

P110 |

|

White |

None |

One White |

|

|

Q125 |

|

Orange |

None |

One Orange |

|

Casing coupling and tubing coupling are manufactured according to API 5CT and 5B specifications.

API 5CT--This standard specifies the technical delivery conditions for steel pipes (casing, tubing, and pup joints), coupling stock, coupling material, and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all grades except H-40, L-80 9Cr, and C110, are contained in Annex H. This standard can also be applied to tubular with connections not covered by API standards,Not applicable to threading requirements.

API 5B--API 5B is the standard specification for threading, gauging, and inspection of Casing, Tubing and line pipe threads.

Spec 5B covers dimensions and marking requirements for API Master thread gauges. Additional product threads and thread gauges, as well as instruments and methods for the inspection of threads for line pipe, round thread casing, buttress casing, and extreme-line casing connections, are included. It is applicable when so stipulated in the API standard governing the product. The inspection procedures for measurements of taper, lead, height, and angle of thread are applicable to threads having 111/2 or less turns per in. (111/2 or less turns per 25.4 mm). All thread dimensions shown without tolerances are related to the basis for connection design and are not subject to measurement to determine acceptance or rejection of product.

Chemical Composition(%)

|

Chemical Composition(%) |

|||||||||

|

Grade |

C |

Mn |

Mo |

Cr |

Ni |

Cu |

P |

S |

Si |

|

H40 |

|

|

|

|

|

|

≤0.03 |

≤0.03 |

— |

|

J55/K55 |

|

|

|

|

|

|

≤0.03 |

≤0.03 |

— |

|

N80-1/N80Q |

|

|

|

|

|

|

≤0.03 |

≤0.03 |

— |

|

R95 |

≤0.45ᶜ |

≤1.9 |

|

|

|

|

≤0.03 |

≤0.03 |

— |

|

L80 |

≤0.43ᵃ |

≤1.9 |

|

|

|

|

≤0.03 |

≤0.03 |

— |

|

L80-1 |

≤0.15 |

0.30~0.60 |

0.90~1.10 |

8.00~10.0 |

— |

— |

≤0.03 |

≤0.03 |

≤0.45 |

|

L80-13Cr |

0.15~0.22 |

0.25~1.00 |

|

12.0~14.0 |

≤0.25 |

≤0.35 |

≤0.03 |

≤0.03 |

≤0.45 |

|

C90 |

≤0.35 |

≤1.20 |

0.25ᵇ~0.85 |

≤1.50 |

≤0.5 |

≤0.25 |

≤0.02 |

≤0.01 |

≤1 |

|

T95 |

≤0.35 |

≤1.20 |

0.25ᵇ~0.85 |

0.40~1.50 |

≤0.5 |

≤0.25 |

≤0.02 |

≤0.01 |

≤1 |

|

C110 |

≤0.35 |

≤1.20 |

0.25~1.00 |

0.40~0.15 |

≤0.99 |

— |

≤0.02 |

≤0.01 |

— |

|

P110 |

|

|

|

|

≤0.99 |

— |

≤0.02 |

≤0.01 |

— |

|

Q125 |

≤0.35 |

1.35 |

≤0.85 |

≤1.50 |

≤0.99 |

— |

≤0.02 |

≤0.005 |

— |

Mechanical properties

|

Mechanical properties |

|||||

|

Grade |

Total elongation under load(%) |

Yield strength(Mpa) |

Tensile strength(Mpa) |

Hardness(HRC) |

Hardness(HBW) |

|

H40 |

0.5 |

276~552 |

414 |

— |

— |

|

J55 |

0.5 |

379~552 |

517 |

— |

— |

|

K55 |

0.5 |

379~552 |

655 |

— |

— |

|

N80-1/N80Q |

0.5/0.5 |

552~758/552~758 |

689/689 |

— |

— |

|

R95 |

0.5 |

655 |

724 |

— |

— |

|

L80 |

0.5 |

552 |

655 |

23.0 |

241 |

|

L80-1/L80-9Cr |

0.5 |

552 |

655 |

23.0 |

241 |

|

L80-13Cr |

0.5 |

552 |

655 |

23.0 |

241 |

|

C90 |

0.5 |

621 |

689 |

25.4 |

255 |

|

T95 |

0.5 |

655 |

724 |

25.4 |

255 |

|

C110 |

0.7 |

758 |

793 |

30.0 |

286 |

|

P110 |

0.6 |

758 |

862 |

— |

— |

|

Q125 |

0.65 |

862 |

931 |

b |

— |

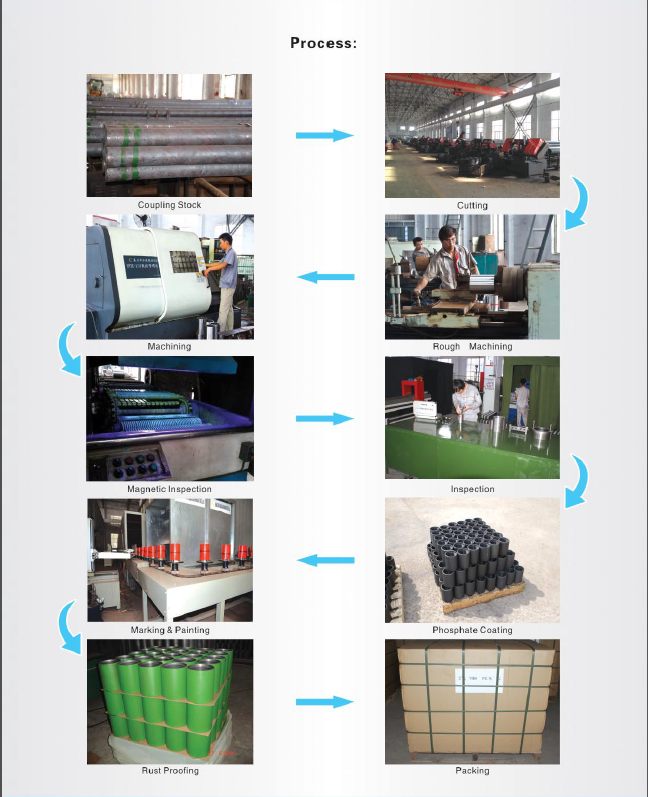

Pipe Process of API 5CT Couplings

Round Pipe → pipe inspection → NDT inspection MPI → End Threading → Thread Inspection → Coupling Threading lnspection → NDT inspection MPI ( coupling) → Phosphating (for coupling) → Coupling power Make up → Hydrostatic test → Drift test → Doping and Protectors Application → Coating → Measurement of Length and Weight → Colour Identification → Marking → Packing → Warehousing

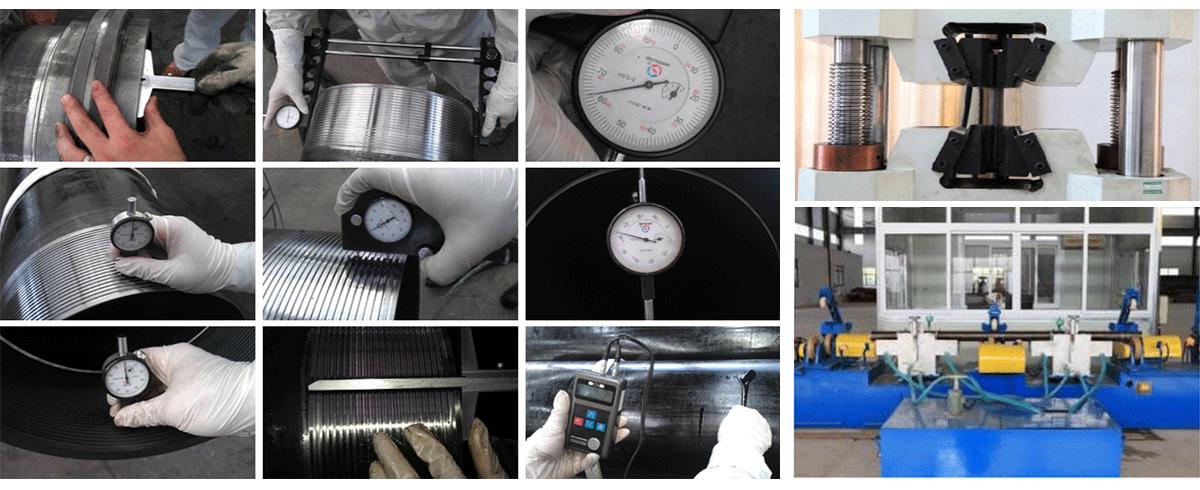

Test & Inspection

According to API 5CT,API 5B or customer specified standards strict inspection and test system is used before shipping including appearance inspection, dimension inspection, chemical composition inspection, performance test, strength test, tensile test, hardness test, NDT, hydrostatic test, etc. The great products will be supplied and there is no worry about the quality.