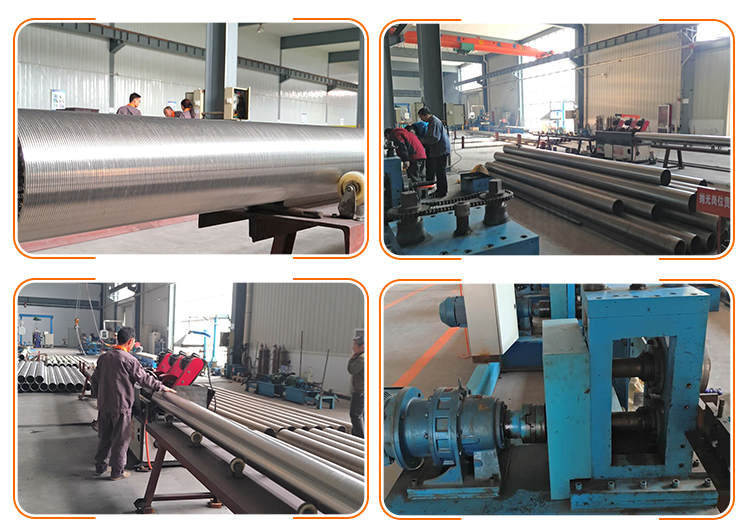

We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

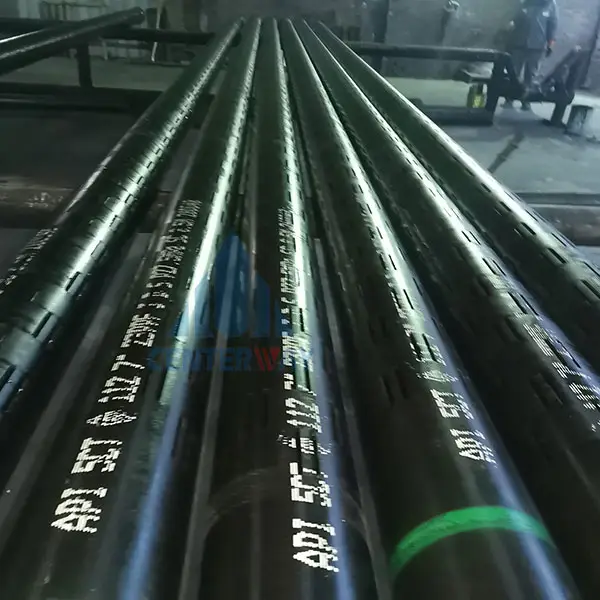

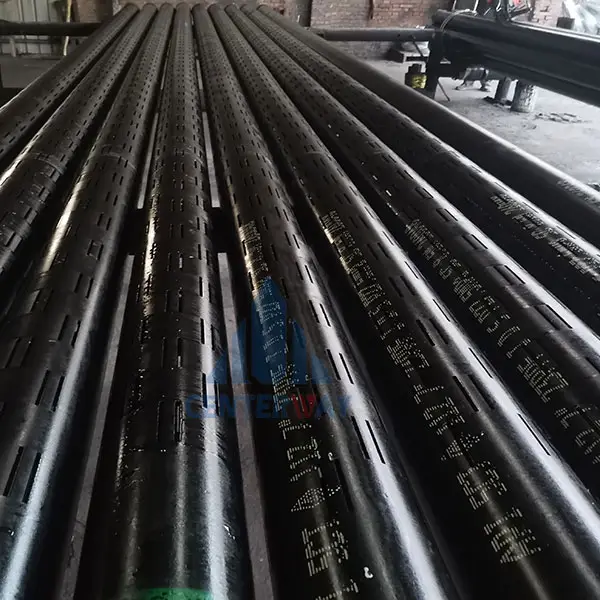

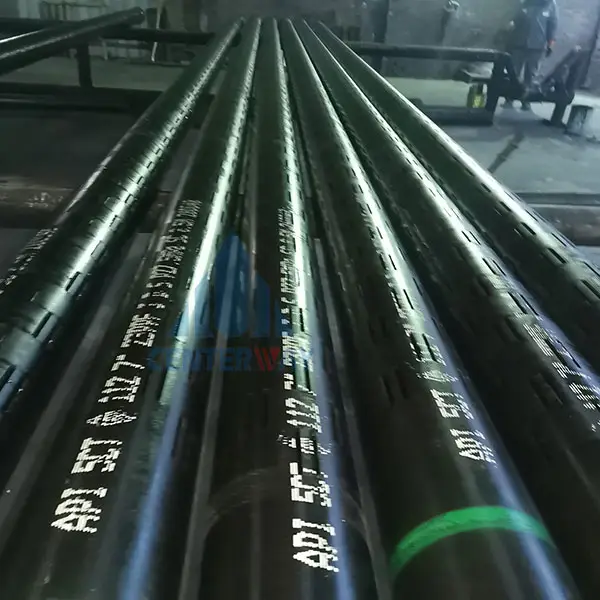

Slot and perforate on the pipe body to be slotted pipes. The types of slot are Perforated, Rectangular slotted, Trapezoid slotted, Bridge slotted, Wire wrapped screen, Mechanical cutting, Compound slotted pipe.

The slotted pipe is using in oil exploration to prevent sand, decrease oil well repaired, increase oil well’s strength, integrality and stability of keeping off sand.

1.Casing slotted pipe specification:

O.D.: Casing: 4 1/2″-20″ (114.3mm-508mm)

Tubing:1.05″-41/2″(26.7mm-114.3m)

Length:R1:4.88-7.62M,R2:7.621-10.36M,R3:10.36-14.63M

W.T.: 0.205” – 0.875” (5.21mm- 22.22mm)

Product standards: API 5CT, BS EN ISO11960, NFM87-207, JIS G3439, ISO 4270, GOST 632-80

Material: H40, J55, K55, N80-1, N80Q, R95, L80-1, L80-9Cr, L80-13Cr, C90, T95, C110, P110, Q125

2. Thread type:

Casing: STC, LTC, BTC etc.

Tubing: NU, EU, XL, PH-4, PH-6, LTC, STC, BTC etc.

3. Slotted type

(1)Straight Slots

Cut at a right angle to the liner, this slot type shows the same diameter from the inside to the outside of the wall. Although straight slots are cheaper to produce, they are less effective in sand control compared to keystone slots.

(2)Keystone Slots

Cut at a slight angle, keystone slots, or tapered slots, are larger on the inside than on the outside, making sure that any particle entering the slot can pass through freely without clogging the slot.

Keystone slots are more expensive to than straight slots, but lower the risk of production losses due to plugged liner slots.

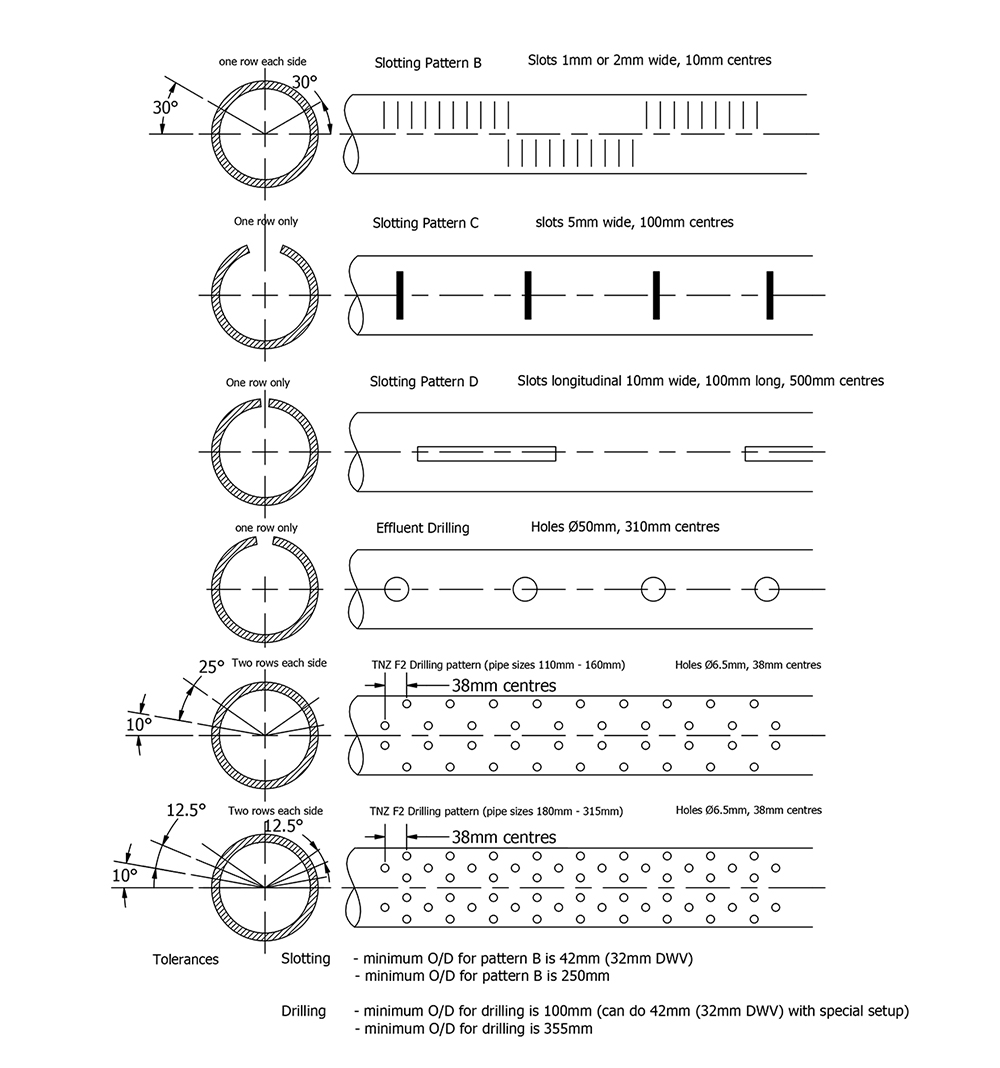

(3)Slot Patterns

Whether you want your slotted pipe with a line, staggered, gang, overlapping, horizontal, or any other pattern, we can cut them all.

Among all slot patterns, the following three are the most common.

(4)Line (Straight) Pattern

In the line pattern, slots are placed evenly in identical bands around the pipe, forming straight lines of slots across the length of the slotted liner.

(5)Single-Slot Staggered Pattern

In the single-slot staggered pattern, bands of evenly spaced slots are placed around the pipe. Slots in different bands are offset (staggered) to each other.

The single-slot staggered pattern preserves the strength of the pipe and provides an even distribution of the slots over the area of the pipe.

(6)Gang Pattern (Multiple Staggered Pattern)

While having the same overall layout as the single-slot staggered pattern, the gang pattern places two slots, cut at close proximity, instead of just one slot at each position.

Slotted pipe with a multiple staggered pattern has been shown to withstand higher torque during installation and provide better resistance to deformation under thermal load compared to the single-slot staggered pattern, making it well suited for application in steam assisted gravity drainage (SAGD) applications.

4. Assurance

API/ISO quality system, SGS, DNV, BV, Moody third party inspection welcomed

|

API Casing |

ID |

Length |

Slot Length |

Slot

|

Slot width

|

Slot Tolerance

|

Valid Filter Area

|

Max. Strength

|

||

|

|

|

|

|

|

|

|||||

|

Spec

|

Thickness

|

Per Weight

|

|

|

|

|||||

|

|

|

|

||||||||

|

|

|

|

||||||||

|

60.32 |

5 |

6.84 |

50.3 |

3

|

80

|

200 |

0.3

|

±50

|

48 |

512.54 |

|

73.02 |

5.5 |

9.15 |

62 |

240 |

57.6 |

688.55 |

||||

|

88.9 |

6.5 |

13.22 |

75.9 |

280 |

67.2 |

995.1 |

||||

|

101.6 |

6.5 |

15.22 |

88.6 |

300 |

72 |

1151.2 |

||||

|

114.3 |

7 |

18.47 |

100.3 |

10

|

320 |

76.8 |

1400.4 |

|||

|

127 |

7.52 |

22.13 |

112 |

340 |

81.6 |

1673.8 |

||||

|

139.7

|

7.72 |

25.11 |

124.3 |

360 |

86.4 |

1900.2 |

||||

|

9.17 |

29.48 |

121.4 |

360 |

86.4 |

2232.4 |

|||||

|

168.3 |

8.94 |

35.09 |

150.4 |

400 |

96 |

2672.95 |

||||

|

177.8

|

8.05 |

33.68 |

161.7 |

440 |

105.6 |

2559.2 |

||||

|

9.19 |

38.19 |

159.4 |

440 |

105.6 |

2940.7 |

|||||

API Spec 5CT – Specification 5CT/ISO 11960,GB/T 19830-2011 Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

Mechanical Properties:

|

Group |

Grade |

Type |

Total elongation under load % |

Yield Strength M pa |

Tensile strength min Mpa |

Hardness |

||

|

min |

max |

HRC |

HBW |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

2 |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

3 |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

C90 |

|

0.5 |

621 |

689 |

689 |

25.4 |

255 |

|

|

C95 |

- |

0.5 |

655 |

724 |

724 |

- |

- |

|

|

T95 |

|

0.5 |

655 |

724 |

724 |

25.4 |

255 |

|

|

P110 |

- |

0.6 |

758 |

862 |

862 |

- |

- |

|

|

4 |

Q125 |

All |

0.65 |

862 |

931 |

931 |

- |

- |

|

Standard |

Grade |

Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

AIs |

||

|

API SPEC 5CT |

J55K55 |

0.34~0.39 |

0.20~ |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

(37Mn5) |

||||||||||||

|

N80 |

0.34~0.38 |

0.20~ |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

|

|

|

0.11 |

≤0.020 |

|

|

(36 Mn2V) |

||||||||||||

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~ |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~ |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~ |

≤0.20 |

≤0.20 |

0.15 |

≤0.08 |

≤0.020 |

|

|

|

||||||||||||