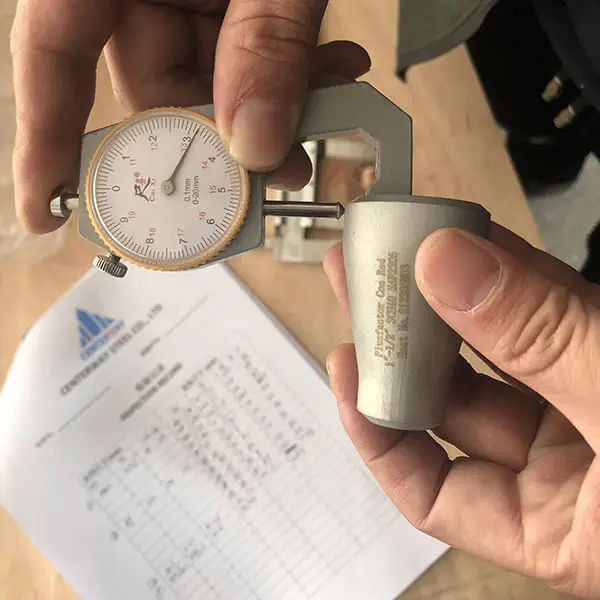

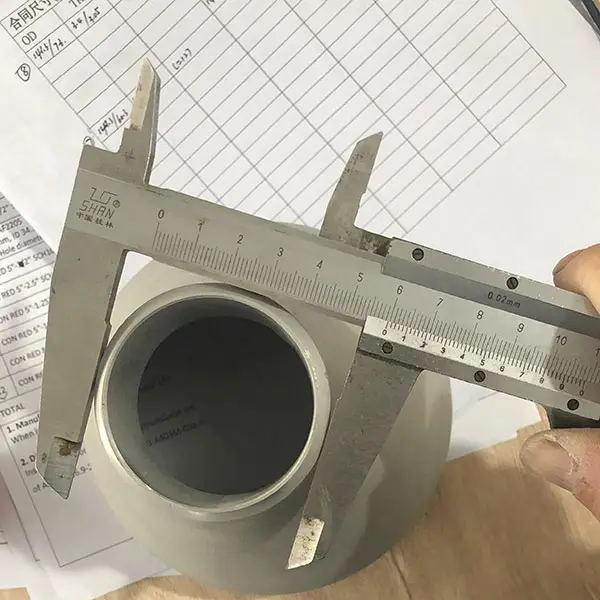

We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

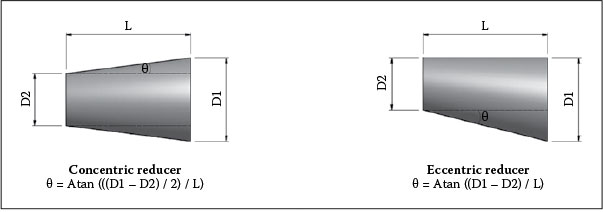

Reducers are usually concentric but eccentric reducers are used when required to maintain the same top-or bottom-of-pipe level.

A reducer can be used either as nozzle or as diffuser depending on the mach number of the flow.

A reducer allows for a change in pipe size to meet hydraulic flow requirements of the system, or to adapt to existing piping of a different size.

Standard: ANSI B16.9 / 16.28, ASTM A53/A106, API 5L,, ASTM/ASME SA234 WP11, WP12, WP22, WP9

Size range: 1/2 to 56 inches (DN15 to DN1400)

Pressure: SCH5 to SCH160

view the fitting end beveling ...

Types: Lare size reducers, stainless pipe reducers, carbon steel reducers, DIN 2617 pipe reducers, DIN 28011 pipe reducers

Concentric Reducer

In Concentric Reducer the reduction of the pipe size is achieved by decreasing the diameter of the fitting at a constant rate over a specified length, maintaining symmetry around the fitting. Concentric Reducers are used to join pipe or tube sections of different diameters on the same axis. They provide an in-line conical transition between pressurized pipes of differing diameters. Thus, concentric reducers connect pipes of unequal size but have a common centerline. The same fitting can be used in reverse as an concentric expander.

Eccentric Reducer

In Eccentric Reducer the reduction of the pipe size is achieved by decreasing the diameter of the fitting at a constant rate over a specified length, maintaining one side of the fitting horizontally. An eccentric pipe reducer fitting is manufactured with the smaller outlet off center to the larger end, which allows it to align with only one side of the inlet. The same fitting can be used in reverse as an eccentric expander.

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

3/4 |

1/2 |

26.7 |

21.3 |

38 |

|

3/4 |

3/8 |

26.7 |

17.3 |

38 |

|

1 |

3/4 |

33.4 |

26.7 |

51 |

|

1 |

1/2 |

33.4 |

21.3 |

51 |

|

1-1/4 |

1 |

42.2 |

33.4 |

51 |

|

1-1/4 |

3/4 |

42.2 |

26.7 |

51 |

|

1-1/4 |

1/2 |

42.2 |

21.3 |

51 |

|

1-1/2 |

1-1/4 |

48.3 |

42.2 |

64 |

|

1-1/2 |

1 |

48.3 |

33.4 |

64 |

|

1-1/2 |

3/4 |

48.3 |

26.7 |

64 |

|

1-1/2 |

1/2 |

48.3 |

21.3 |

64 |

|

2 |

1-1/2 |

60.3 |

48.3 |

76 |

|

2 |

1-1/4 |

60.3 |

42.2 |

76 |

|

2 |

1 |

60.3 |

33.4 |

76 |

|

2 |

3/4 |

60.3 |

26.7 |

76 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

2-1/2 |

2 |

73.0 |

60.3 |

89 |

|

2-1/2 |

1-1/2 |

73.0 |

48.3 |

89 |

|

2-1/2 |

1-1/4 |

73.0 |

42.2 |

89 |

|

2-1/2 |

1 |

73.0 |

33.4 |

89 |

|

3 |

2-1/2 |

88.9 |

73.0 |

89 |

|

3 |

2 |

88.9 |

60.3 |

89 |

|

3 |

1-1/2 |

88.9 |

48.3 |

89 |

|

3 |

1-1/4 |

88.9 |

42.2 |

89 |

|

3-1/2 |

3 |

101.6 |

88.9 |

102 |

|

3-1/2 |

2-1/2 |

101.6 |

73.0 |

102 |

|

3-1/2 |

2 |

101.6 |

60.3 |

102 |

|

3-1/2 |

1-1/2 |

101.6 |

48.3 |

102 |

|

3-1/2 |

1-1/4 |

101.6 |

42.2 |

102 |

|

4 |

3-1/2 |

114.3 |

101.6 |

102 |

|

4 |

3 |

114.3 |

88.9 |

102 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

4 |

2-1/2 |

114.3 |

73.0 |

102 |

|

4 |

2 |

114.3 |

60.3 |

102 |

|

4 |

1-1/2 |

114.3 |

48.3 |

102 |

|

5 |

4 |

141.3 |

114.3 |

127 |

|

5 |

3-1/2 |

141.3 |

101.6 |

127 |

|

5 |

3 |

141.3 |

88.9 |

127 |

|

5 |

2-1/2 |

141.3 |

73.0 |

127 |

|

5 |

2 |

141.3 |

60.3 |

127 |

|

6 |

5 |

168.3 |

141.3 |

140 |

|

6 |

4 |

168.3 |

114.3 |

140 |

|

6 |

3-1/2 |

168.3 |

101.6 |

140 |

|

6 |

3 |

168.3 |

88.9 |

140 |

|

6 |

2-1/2 |

168.3 |

73.0 |

140 |

|

8 |

6 |

219.1 |

168.3 |

152 |

|

8 |

5 |

219.1 |

141.3 |

152 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

8 |

4 |

219.1 |

114.3 |

152 |

|

8 |

3-1/2 |

219.1 |

101.6 |

152 |

|

10 |

8 |

273.0 |

219.1 |

178 |

|

10 |

6 |

273.0 |

168.3 |

178 |

|

10 |

5 |

273.0 |

141.3 |

178 |

|

10 |

4 |

273.0 |

114.3 |

178 |

|

12 |

10 |

323.8 |

273.0 |

203 |

|

12 |

8 |

323.8 |

219.1 |

203 |

|

12 |

6 |

323.8 |

168.3 |

203 |

|

12 |

5 |

323.8 |

141.3 |

203 |

|

14 |

12 |

355.6 |

323.8 |

330 |

|

14 |

10 |

355.6 |

273.0 |

330 |

|

14 |

8 |

355.6 |

219.1 |

330 |

|

14 |

6 |

355.6 |

168.3 |

330 |

|

16 |

14 |

406.4 |

355.6 |

356 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

16 |

12 |

406.4 |

323.8 |

356 |

|

16 |

10 |

406.4 |

273.0 |

356 |

|

16 |

8 |

406.4 |

219.1 |

356 |

|

18 |

16 |

457.0 |

406.4 |

381 |

|

18 |

14 |

457.0 |

355.6 |

381 |

|

18 |

12 |

457.0 |

323.8 |

381 |

|

18 |

10 |

457.0 |

273.0 |

381 |

|

20 |

18 |

508.0 |

457.0 |

508 |

|

20 |

16 |

508.0 |

406.4 |

508 |

|

20 |

14 |

508.0 |

355.6 |

508 |

|

20 |

12 |

508.0 |

323.8 |

508 |

|

22 |

20 |

559.0 |

508.0 |

508 |

|

22 |

18 |

559.0 |

457.0 |

508 |

|

22 |

16 |

559.0 |

406.4 |

508 |

|

22 |

14 |

559.0 |

355.4 |

508 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

24 |

22 |

610.0 |

559.0 |

508 |

|

24 |

20 |

610.0 |

508.0 |

508 |

|

24 |

18 |

610.0 |

457.0 |

508 |

|

24 |

16 |

610.0 |

406.4 |

508 |

|

26 |

24 |

660.0 |

610.0 |

610 |

|

26 |

22 |

660.0 |

559.0 |

610 |

|

26 |

20 |

660.0 |

508.0 |

610 |

|

26 |

18 |

660.0 |

457.0 |

610 |

|

28 |

26 |

711.0 |

660.0 |

610 |

|

28 |

24 |

711.0 |

610.0 |

610 |

|

28 |

20 |

711.0 |

508.0 |

610 |

|

28 |

18 |

711.0 |

457.0 |

610 |

|

30 |

28 |

762.0 |

711.0 |

610 |

|

30 |

26 |

762.0 |

660.0 |

610 |

|

30 |

24 |

762.0 |

610.0 |

610 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

30 |

20 |

762.0 |

508.0 |

610 |

|

32 |

30 |

813.0 |

762.0 |

610 |

|

32 |

28 |

813.0 |

711.0 |

610 |

|

32 |

26 |

813.0 |

660.0 |

610 |

|

32 |

24 |

813.0 |

610.0 |

610 |

|

34 |

32 |

864.0 |

813.0 |

610 |

|

34 |

30 |

864.0 |

762.0 |

610 |

|

34 |

26 |

864.0 |

660.0 |

610 |

|

34 |

24 |

864.0 |

610.0 |

610 |

|

36 |

34 |

914.0 |

864.0 |

610 |

|

36 |

32 |

914.0 |

813.0 |

610 |

|

36 |

30 |

914.0 |

762.0 |

610 |

|

36 |

26 |

914.0 |

660.0 |

610 |

|

36 |

24 |

914.0 |

610.0 |

610 |

|

38 |

36 |

965.0 |

914.0 |

610 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

38 |

34 |

965.0 |

864.0 |

610 |

|

38 |

32 |

965.0 |

813.0 |

610 |

|

38 |

30 |

965.0 |

762.0 |

610 |

|

38 |

28 |

965.0 |

711.0 |

610 |

|

38 |

26 |

965.0 |

660.0 |

610 |

|

40 |

38 |

1016.0 |

965.0 |

610 |

|

40 |

36 |

1016.0 |

914.0 |

610 |

|

40 |

34 |

1016.0 |

864.0 |

610 |

|

40 |

32 |

1016.0 |

813.0 |

610 |

|

40 |

30 |

1016.0 |

762.0 |

610 |

|

42 |

40 |

1067.0 |

1016.0 |

610 |

|

42 |

38 |

1067.0 |

965.0 |

610 |

|

42 |

36 |

1067.0 |

914.0 |

610 |

|

42 |

34 |

1067.0 |

864.0 |

610 |

|

42 |

32 |

1067.0 |

813.0 |

610 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

42 |

30 |

1067.0 |

762.0 |

610 |

|

44 |

42 |

1118.0 |

1067.0 |

610 |

|

44 |

40 |

1118.0 |

1016.0 |

610 |

|

44 |

38 |

1118.0 |

965.0 |

610 |

|

44 |

36 |

1118.0 |

914.0 |

610 |

|

46 |

44 |

1168.0 |

1118.0 |

711 |

|

46 |

42 |

1168.0 |

1067.0 |

711 |

|

46 |

40 |

1168.0 |

1016.0 |

711 |

|

46 |

38 |

1168.0 |

965.0 |

711 |

|

48 |

46 |

1219.0 |

1168.0 |

711 |

|

48 |

44 |

1219.0 |

1118.0 |

711 |

|

48 |

42 |

1219.0 |

1067.0 |

711 |

|

48 |

40 |

1219.0 |

1016.0 |

711 |

|

NPS1 |

NPS2 |

OD1 |

OD2 |

H |

|

ASME: |

ANSI B16.9, ANSI B16.28, MSS-SP-43 |

|

DIN: |

DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

|

EN: |

EN10253-1, EN10253-2 |

|

ASTM A403 – ASME SA403 |

Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

|

ASME B16.9 |

Factory-Made Wrought Fittings Buttwelding |

|

ASME B16.25 |

Buttwelding Ends |

|

ASME B16.28 |

Wrought Steel Short Radius Elbows and Buttwelding Returns |

|

MSS SP-43 |

Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

|

Stainless Steel Reducer |

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

|

Carbon Steel Reducer |

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

|

Low Temperature Carbon Steel Reducer |

ASTM A420 WPL3, A420 WPL6 |

|

Alloy Steel Reducer |

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

|

Duplex Reducer |

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

|

Nickel Alloy Reducer |

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |