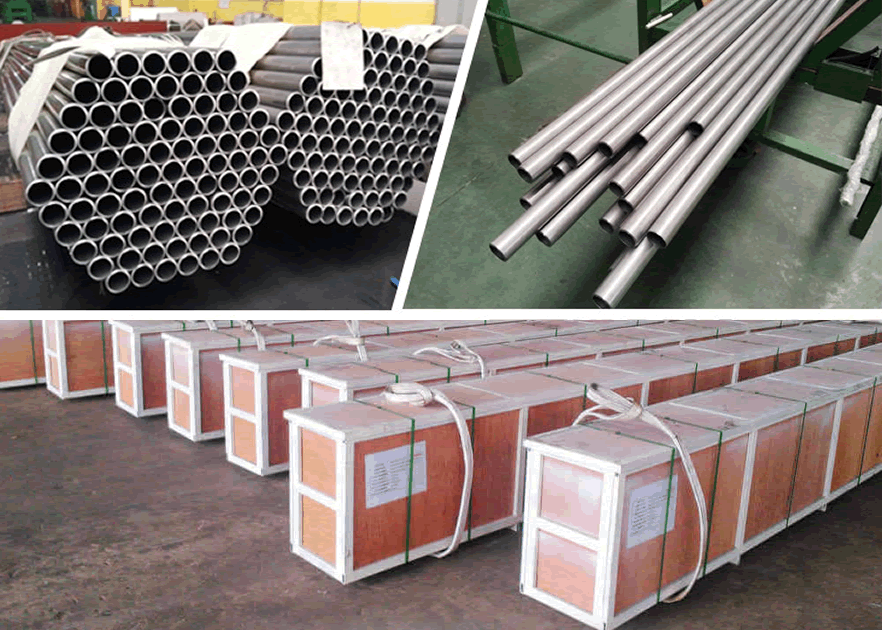

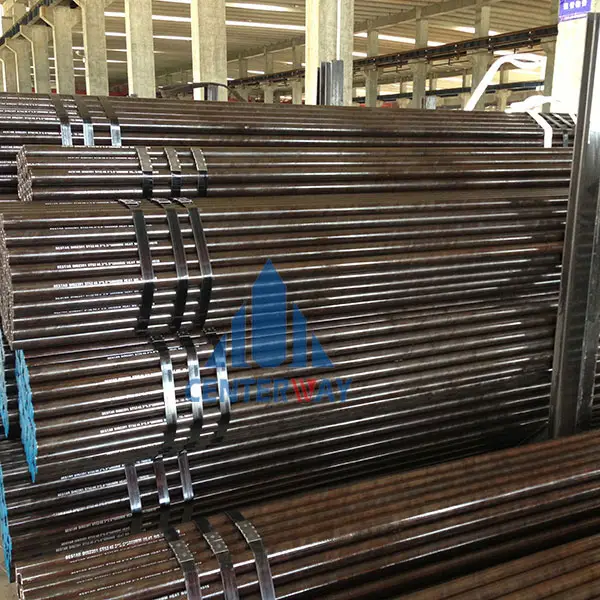

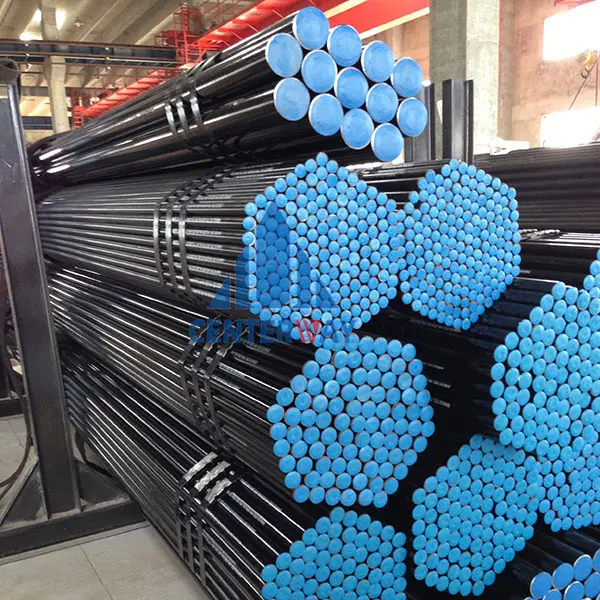

We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

Fire Tube Boiler

Fire-tube boiler is a type of boiler in which hot gas passes from the fire through one or more pipes that pass through a sealed water container. The heat of the gas is transferred through the wall of the tube through heat conduction, heating the water and eventually generating steam. Fire tube boilers are the third of the four historical types of boilers: low-pressure tank or “haystack” boilers, flue boilers with one or two large flues, fire tube boilers and high-pressure boilers with many small tubes

Water Tube Boiler

Water tube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. The fuel is burned in the furnace to produce hot gas, which heats the water in the steam generation tube. In smaller boilers, the additional power generation tubes are separated in the furnace, while larger utility boilers rely on water injection tubes that make up the furnace wall to generate steam. High-pressure water tube boiler: The hot water then rises into the steam drum. Here, saturated steam is drawn away from the top of the drum.

|

A179 |

Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

|

A192 |

Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

|

A210 |

Standard Specification for Seamless Medium-Carbon Steel Boiler and Super heater Tubes |

|

A556 |

Specification for Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes |

Boiler tubing is used in these industries:

Steam Boilers

Power Generation

Fossil Fuel Plants

Electric Power Plants

Industrial Processing Plants

Cogeneration Facilities

Boiler tubes need to withstand high pressure and temperature.

Boiler pipe size range complied with the different ASTM standard required. Like ASTM A106 or ASTM 179, 192 etc.

Straightness of boiler tubes:Allowed straightness is 0.0015 multiple of the tube length, for 1 meter length the allowed straightness is 3 millimeters.

|

Size |

Wall Thickness(mm) |

|||||||||||||

|

O.D.(mm) |

2 |

2.5 |

3 |

3.5 |

4 |

4.5 |

5 |

6 |

6.5-7 |

7.5-8 |

8.5-9 |

9.5-10 |

11 |

12 |

|

Φ25-Φ28 |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

Φ32 |

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Φ34-Φ36 |

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Φ38 |

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Φ40 |

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Φ42 |

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Φ45 |

|

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

Φ48-Φ60 |

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

Φ63.5 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

Φ68-Φ73 |

|

|

|

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

Φ76 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ80 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ83 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ89 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ95 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ102 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ108 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ114 |

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ121 |

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

Φ127 |

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

GB(Chinese National standards)

GB 3087: Seamless steel tubes for low and medium pressure boiler

GB 5310: Seamless steel tube for high pressure boiler

GB 13296: Seamless steel tubes for boilers and heat exchangers

GB 6479: Seamless steel tubes for high-pressure chemical fertilizer equipment

GB 9948: Seamless steel tubes for petroleum cracking

ASME(American society of mechanical engineers)

ASME SA-106: Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

ASME SA-192M: Seamless Carbon Steel Boiler Tubes for High Pressure

ASME SA-209M: Seamless carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes

ASME SA-210M: Seamless Medium-carbon Steel Boiler and Superheater Tubes

ASME SA-213M: Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes

ASME SA178: Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater

ASTM(Chinese National standards)

ASTM A213: Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes

SA213-T2: ASME SA213 T2 has allowable stresses listed up to 1000F in the ASME Boiler Code.

SA213-T9

SA213-T12: Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

SA213-T11: The tubes are used in heat exchangers, super heaters and in boilers.

SA213-T22: ASM T22 Boiler Tube is a high temperature tolerance tube that is used in acidic and corrosive environments such as the hydrochloric processing and in aluminum chloride catalyst involving applications.

ASTM A 106M: Seamless Carbon Steel Pipe for High-Temperature Service

ASTM A192M: Seamless Carbon Steel Boiler Tubes for High Pressure

ASTM A210M: Seamless Medium-carbon Steel Boiler and Superheater Tubes

ASTM A 335M: Seamless ferritic alloy-steel pipe for high-temperature service

EN(Deutsche industrie normen)

EN 10216-2 : Seamless steel tubes for pressure purposes

DIN(Deutsche industrie normen)

DIN 17175:Seamless Tubes of Heat-resistant Steels - Technical Conditions of Delivery

JIS(Japanese industrial standards)

JIS G3461: Carbon steel boiler and heat exchanger tubes

JIS G3462: Alloy steel boiler and heat exchanger tubes

JIS G3463: Stainless Steel for Boiler and Heat Exchanger Tubes

STAINLESS STEELS

– Austenitic stainless steels

SA213-T304:– The SA 213 Tp 304 Material consists of 18% chromium and carbon, manganese, phosphorus, sulfur, silicon and nickel in the composition.

SA213-T316: – SA213 TP316 Tube is a material standard for heat exchanger tubes that are made from 316 austenitic stainless steel.

SA213-TP321 & 347– SA213 TP321 is a specification of heat exchanger tubes that are made from the 321 austenitic stainless steel.