We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

Application: In Structural Engineering and Construction Industry

Specification: OD: 1/8'' ~ 26'' (10.3 ~ 660mm)

WT: SCH 10 ~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard: ASTM A53/A252/A500/A501, JIS G3444, EN 10210/10219

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

|

Grade |

C, max |

Mn, max |

P, max |

S, max |

|

|

A53 |

A |

0.25 |

0.95 |

0.05 |

0.05 |

|

B |

0.3 |

1.2 |

0.05 |

0.05 |

|

|

A519 |

1026 |

0.28 |

0.9 |

0.04 |

0.05 |

|

A252 |

S235JRH |

0.17 |

1.4 |

0.04 |

0.04 |

|

S275JOH |

0.2 |

1.5 |

0.035 |

0.035 |

|

|

S275J2H |

0.2 |

1.5 |

0.03 |

0.03 |

|

|

S355JOH |

0.22 |

1.6 |

0.035 |

0.035 |

|

|

S355J2H |

0.22 |

1.6 |

0.03 |

0.03 |

|

|

S355K2H |

0.22 |

1.6 |

0.03 |

0.03 |

|

|

A500 |

A |

0.26 |

1.35 |

0.035 |

0.035 |

|

B |

0.30 |

1.40 |

0.045 |

0.045 |

|

|

C |

0.23 |

1.35 |

0.035 |

0.035 |

|

|

D |

0.27 |

1.40 |

0.045 |

0.045 |

|

|

Plain End |

Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

|

Plain End (Square Cut) |

Wall Thickness over 0.5 inch, including SCH XXS |

|

Beveled End |

Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

|

Couplings |

Outside Diameter equal or less than 2'' |

|

Thread Protection |

Outside Diameter over 4 inch |

|

NPS |

Outside |

Wall Thickness(mm) |

|||||||||||||||||||||||

|

1/8 |

10.3 |

1.24 |

1.45 |

1.73 |

2.41 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/4 |

13.7 |

1.65 |

1.85 |

224 |

3.02 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/8 |

17.1 |

1.65 |

1.85 |

2.31 |

3.20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/2 |

21.3 |

2.77 |

3.73 |

4.78 |

7.47 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/4 |

26.7 |

2.11 |

2.41 |

2.87 |

3.91 |

5.56 |

7.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

33.4 |

2.77 |

2.90 |

3.38 |

4.55 |

6.35 |

9.09 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-1/4 |

42.2 |

2.77 |

2.97 |

3.56 |

4.85 |

6.35 |

9.70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-1/2 |

48.3 |

2.77 |

3.18 |

3.68 |

5.08 |

7.14 |

10.15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

60.3 |

2.11 |

2.77 |

3.18 |

3.58 |

3.91 |

4.37 |

4.78 |

5.54 |

6.35 |

7.14 |

8.74 |

11.07 |

|

|

|

|

|

|

|

|

|

|

|

|

|

21/2 |

73 |

2.77 |

3.05 |

3.18 |

3.56 |

3.96 |

4.37 |

4.78 |

5.16 |

5.49 |

6.35 |

7.01 |

9.35 |

14.02 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

88.9 |

4.37 |

4.78 |

5.49 |

6.35 |

7.14 |

7.62 |

11.13 |

15.24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

31/2 |

101.6 |

4.78 |

5.74 |

6.35 |

7.14 |

8.08 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

114.3 |

4.78 |

5.16 |

5.56 |

6.02 |

6.35 |

7.14 |

7.92 |

8.56 |

11.13 |

13.49 |

17.12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

141.3 |

4.78 |

5.56 |

6.55 |

7.14 |

7.92 |

8.74 |

9.53 |

12.70 |

15.88 |

19.05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

168.3 |

5.16 |

5.56 |

6.35 |

7.11 |

7.92 |

8.74 |

9.53 |

10.97 |

12.70 |

1427 |

15.88 |

18.26 |

18.26 |

19.05 |

21.95 |

2223 |

|

|

|

|

|

|

|

|

|

8 |

219.1 |

6.35 |

7.04 |

7.92 |

8.18 |

8.74 |

9.53 |

10.31 |

11.13 |

12.70 |

14.27 |

15.09 |

15.88 |

18.26 |

19.05 |

20.62 |

2223 |

23.01 |

25.40 |

|

|

|

|

|

|

|

10 |

273 |

6.35 |

7.09 |

7.80 |

8.74 |

9.27 |

11.13 |

12.70 |

14.27 |

15.09 |

15.88 |

18.26 |

20.62 |

21.44 |

22.23 |

23.83 |

25.40 |

28.58 |

31.75 |

|

|

|

|

|

|

|

12 |

323.8 |

6.35 |

7.14 |

7.92 |

8.38 |

8.74 |

9.53 |

10.31 |

11.13 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

21.44 |

22.23 |

23.83 |

25.40 |

26.97 |

28.6 |

31.8 |

33.3 |

|

|

|

14 |

355.6 |

6.35 |

7.14 |

7.92 |

8.74 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.09 |

15.88 |

17.48 |

19.05 |

20.62 |

22.23 |

23.83 |

25.40 |

26.97 |

27.8 |

28.6 |

31.8 |

35.7 |

50.8 |

|

16 |

406.4 |

7.14 |

7.92 |

8.70 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

16.66 |

17.48 |

19.05 |

20.62 |

21.44 |

2223 |

23.83 |

25.40 |

26.19 |

27 |

|

|

|

|

|

18 |

457 |

7.14 |

7.92 |

8.74 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

22.23 |

23.83 |

25.40 |

26.97 |

28.58 |

29.36 |

30.2 |

|

|

|

|

|

20 |

508 |

8.74 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.09 |

15.88 |

17.48 |

19.05 |

20.62 |

22.23 |

23.83 |

25.40 |

26.19 |

26.97 |

28.58 |

30.18 |

31.8 |

|

|

|

|

|

22 |

559 |

8.74 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

22.23 |

23.83 |

25.40 |

26.97 |

28.58 |

30.18 |

31.75 |

33.32 |

34.9 |

|

|

|

|

|

24 |

610 |

8.74 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

2223 |

23.83 |

24.61 |

25.40 |

26.97 |

28.58 |

30.18 |

30.96 |

31.8 |

33.3 |

34.9 |

36.5 |

38.1 |

|

26 |

660 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

22.23 |

23.83 |

25.40 |

|

|

|

|

|

|

|

|

|

|

|

|

28 |

711 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

2223 |

23.83 |

25.40 |

|

|

|

|

|

|

|

|

|

|

|

|

30 |

762 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

22.23 |

23.83 |

25.40 |

26.97 |

28.58 |

30.18 |

31.75 |

|

|

|

|

|

|

|

|

Pipe types |

Pipe Szie(mm) |

Tolerances |

|

|

Hot rolled |

OD |

<50 |

±0.50mm |

|

≥50 |

±1% |

||

|

WT |

<4 |

±12.5% |

|

|

≥4~20 |

+15%, -12.5% |

||

|

>20 |

±12.5% |

||

|

Cold drawn |

OD |

6~10 |

±0.20mm |

|

10~30 |

±0.40mm |

||

|

30~50 |

±0.45 |

||

|

>50 |

±1% |

||

|

WT |

<1 |

±0.15mm |

|

|

>1~3 |

+ 15%, – 10% |

||

|

>3 |

+ 12.5%, – 10% |

||

|

Standard |

Grade |

Chemical Composition (%) |

Mechanical Properties |

||||||

|

ASTM A53 |

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

|

|

|

A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

|

|

|

B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

|

|

|

ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

|

|

|

ASTM A179 |

A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

|

ASTM A192 |

A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

≥331 |

≥207 |

|

|

B |

0.28 |

- |

1.20 |

0.030 |

0.030 |

≥414 |

≥241 |

|

|

|

X42 |

0.28 |

- |

1.30 |

0.030 |

0.030 |

≥414 |

≥290 |

|

|

|

X46 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥434 |

≥317 |

|

|

|

X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥455 |

≥359 |

|

|

|

X56 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥490 |

≥386 |

|

|

|

X60 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥517 |

≥448 |

|

|

|

X65 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥531 |

≥448 |

|

|

|

X70 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥565 |

≥483 |

|

|

|

API 5L PSL2 |

B |

0.24 |

- |

1.20 |

0.025 |

0.015 |

≥414 |

≥241 |

|

|

X42 |

0.24 |

- |

1.30 |

0.025 |

0.015 |

≥414 |

≥290 |

|

|

|

X46 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥434 |

≥317 |

|

|

|

X52 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥455 |

≥359 |

|

|

|

X56 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥490 |

≥386 |

|

|

|

X60 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥517 |

≥414 |

|

|

|

X65 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥531 |

≥448 |

|

|

|

X70 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥565 |

≥483 |

|

|

|

X80 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥621 |

≥552 |

|

|

|

Standard |

Grade |

Chemical Composition |

Mechanical Properties |

|||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

||

|

GB/T8163 |

10 |

0.07-0.14 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.15 |

≤0.25 |

≤0.25 |

335-457 |

≥205 |

≥24 |

|

20 |

0.17-0.24 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

≤0.25 |

410-550 |

≥245 |

≥20 |

|

|

Q345 |

0.12-0.20 |

0.20-0.55 |

1.20-1.60 |

≤0.045 |

≤0.045 |

- |

- |

- |

490-665 |

≥325 |

≥21 |

|

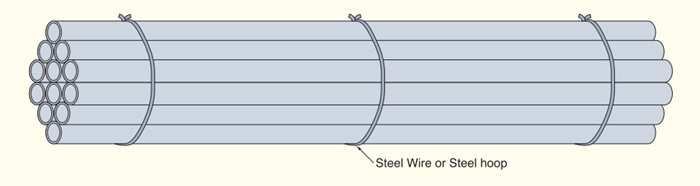

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below

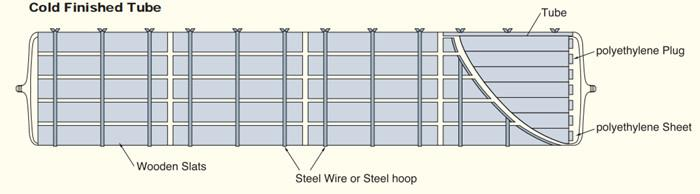

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.