We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

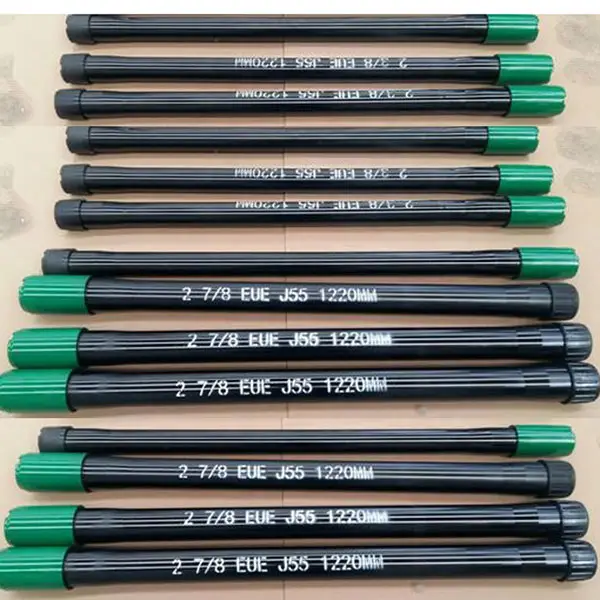

Tubing pup Joint

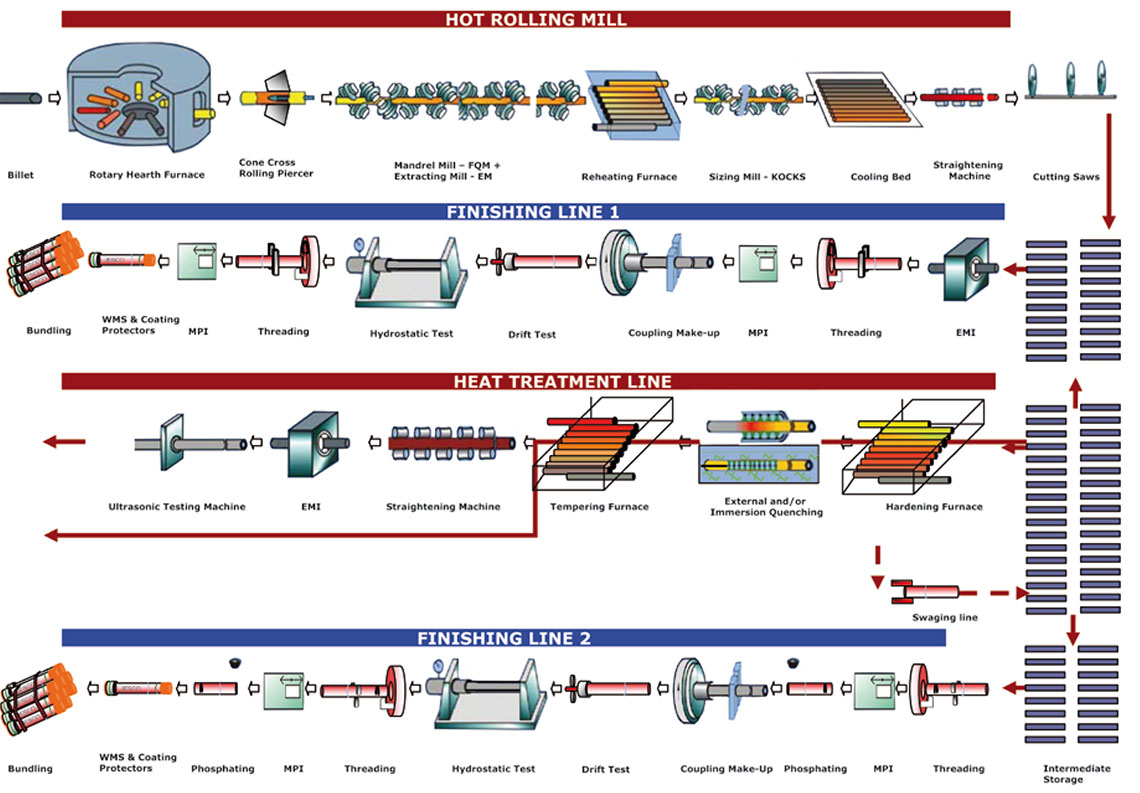

Tubing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of tubings, and tubing pup joints are made of seamless steel tubings. Material grade of tubing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, thread of pup joint can be 8RD, 10RD or BTC, and end connection types can be NUE and EUE. length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Tubing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing. Tubing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joint

Casing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of casings, and casing pup joints are made of seamless steel casings. Material grade of casing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished casing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

|

SPECIFICATIONS |

||||

|

TUBING PUP JOINT |

OD |

GRADE |

END TYPE |

LENGTH(FT) |

|

2 3/8" |

J/K/L/N/P |

NUE/EUE |

2/3/4/5/6/8/10/12 |

|

|

2 7/8" |

J/K/L/N/P |

NUE/EUE |

2/3/4/5/6/8/10/12 |

|

|

3 1/2" |

J/K/L/N/P |

NUE/EUE |

2/3/4/5/6/8/10/12 |

|

|

4 1/2" |

J/K/L/N/P |

NUE/EUE |

2/3/4/5/6/8/10/12 |

|

CASING PUP JOINT

OD

GRADE

END TYPE

4 1/2"

J/K/L/N/P

LTC/STC/BTC

5"

J/K/L/N/P

LTC/STC/BTC

5 1/2"

J/K/L/N/P

LTC/STC/BTC

6 5/8"

J/K/L/N/P

LTC/STC/BTC

7"

J/K/L/N/P

LTC/STC/BTC

7 5/8"

J/K/L/N/P

LTC/STC/BTC

7 3/4"

J/K/L/N/P

LTC/STC/BTC

8 5/8"

J/K/L/N/P

LTC/STC/BTC

9 5/8"

J/K/L/N/P

LTC/STC/BTC

10 3/4"

J/K/L/N/P

STC/BTC

11 3/4"

J/K/L/N/P

STC/BTC

13 3/8"

J/K/L/N/P

STC/BTC

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

Chemical Composition

Standard

Grade

Chemical compositions(%)

API SPEC 5CT

J55

C

Si

Mn

P

S

Cr

Ni

Cu

Mo

V

K55

0.34~0.39

0.20~0.35

1.25~1.50

≤0.020

≤0.015

≤0.15

≤0.20

≤0.20

/

/

N80

0.34~0.38

0.20~0.35

1.45~1.70

≤0.020

≤0.015

≤0.15

/

/

/

0.11~0.16

L80

0.15~0.22

≤1.00

0.25~1.00

≤0.020

≤0.010

12.0~14.0

≤0.20

≤0.20

/

/

P110

0.26~0.395

0.17~0.37

0.40~0.70

≤0.020

≤0.010

0.80~1.10

≤0.20

≤0.20

0.15~0.25

≤0.08

Mechanical properties

Grade

Type

Total elongation under load (%)

Yield strength (min)

Yield strength (max)

Tensile strength min Mpa

Hardness Max (HRC)

Hardness Max (HBW)

J55

-

0.5

379

552

517

-

-

K55

-

0.5

379

552

655

-

-

N80

1

0.5

552

758

689

-

-

N80

Q

0.5

552

758

689

-

-

L80

1

0.5

552

655

655

23

241

L80

9Cr

0.5

552

655

655

23

241

L80

13Cr

0.5

552

655

655

23

241

C90

-

0.5

621

724

689

25.4

255

C95

-

0.5

655

758

724

-

-

T95

-

0.5

655

758

724

25.4

255

P110

-

0.6

758

965

862

-

-

Q125

All

0.65

862

1034

931

-

-