We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

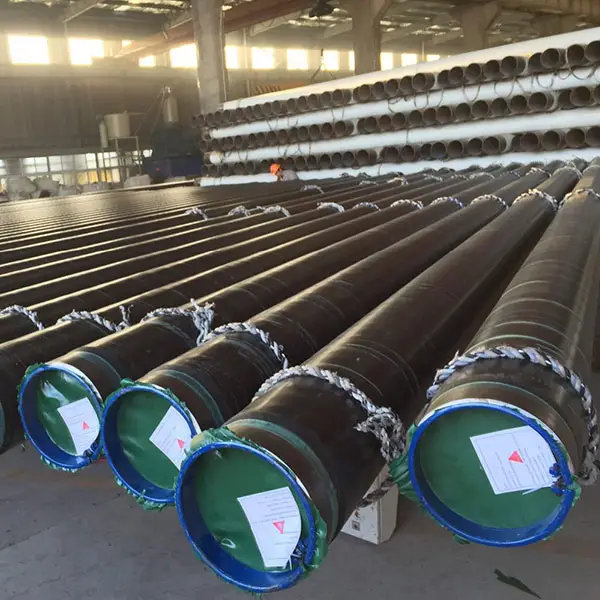

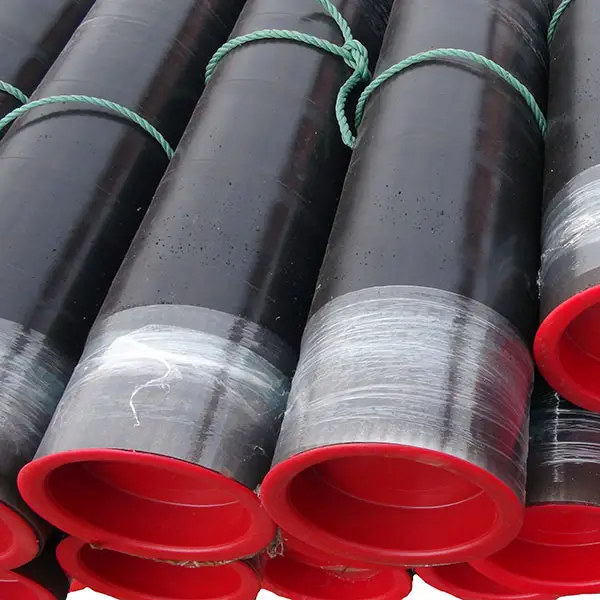

The anti corrosion coating can be used for ERW/LSAW/SSAW pipe,straight seam pipe,seamless steel pipe,etc.And the coated pipes are widely used in pipeline projects in the field of petroleum,chemical, natural gas,heating,sewage treatment,water,bridges,steel structures,piling and other marine water.

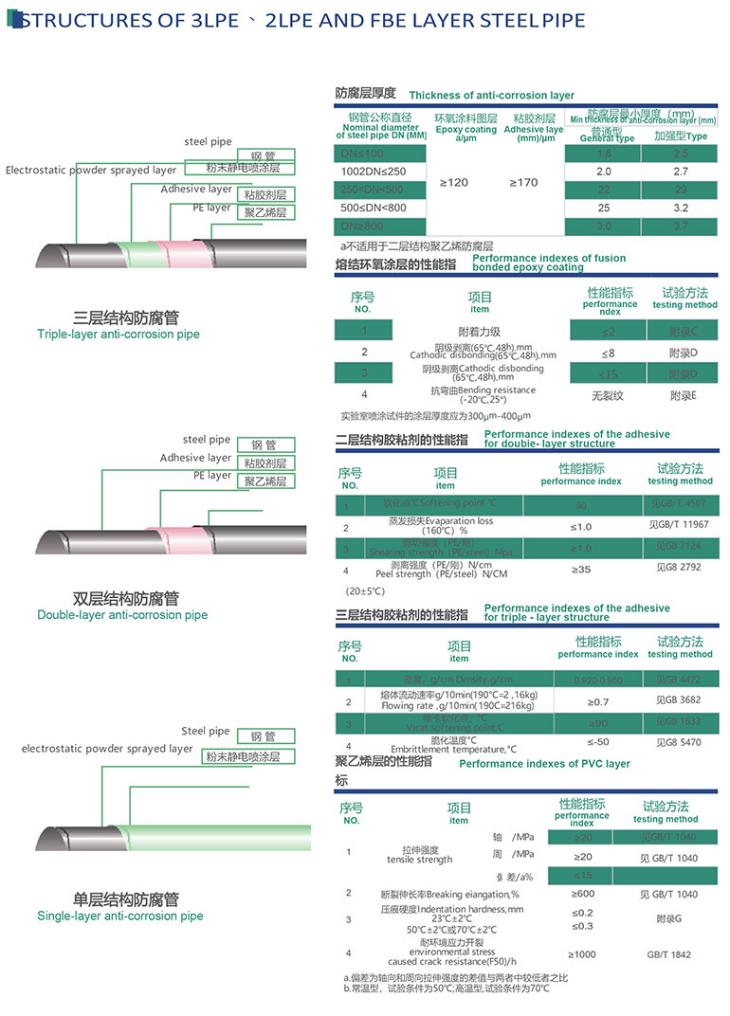

FBE anticorrosive epoxy powder:

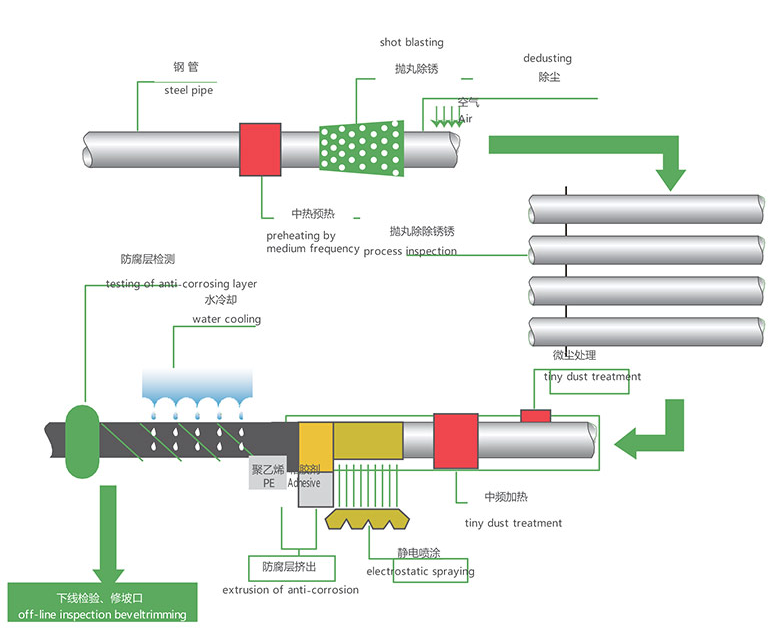

FBE epoxy powder preservative structure:electrostatic spraying epoxy powder coating on the pipe surface,a film.The coating has a coating operation is simple,clean,good impact resistance and flexural properties of the coating, temperature resistance advantages.

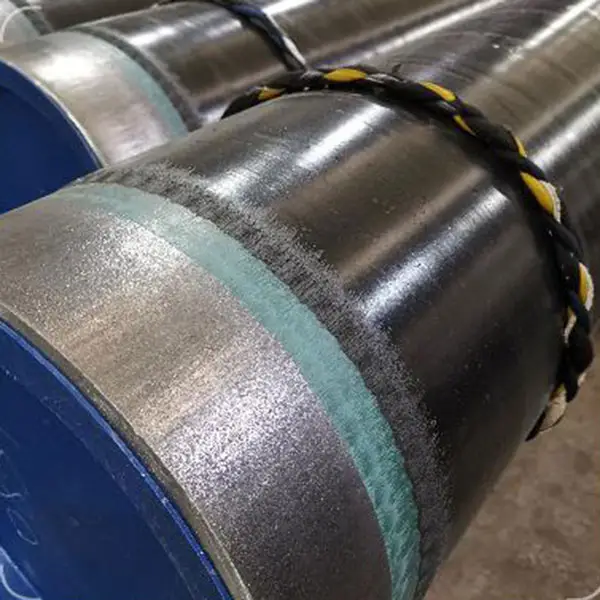

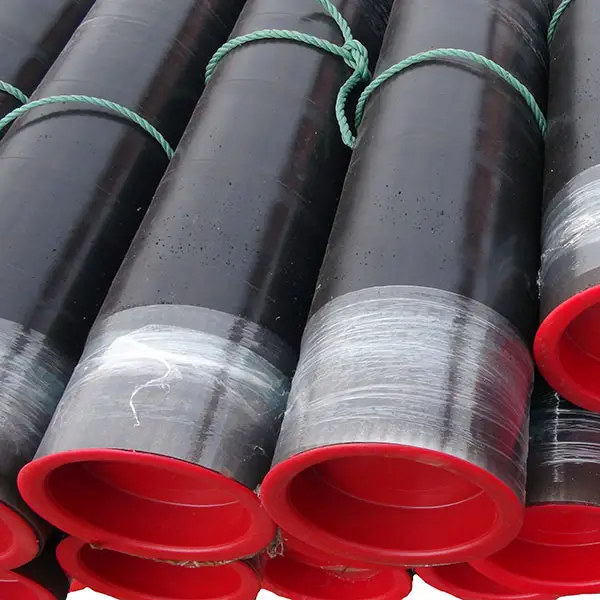

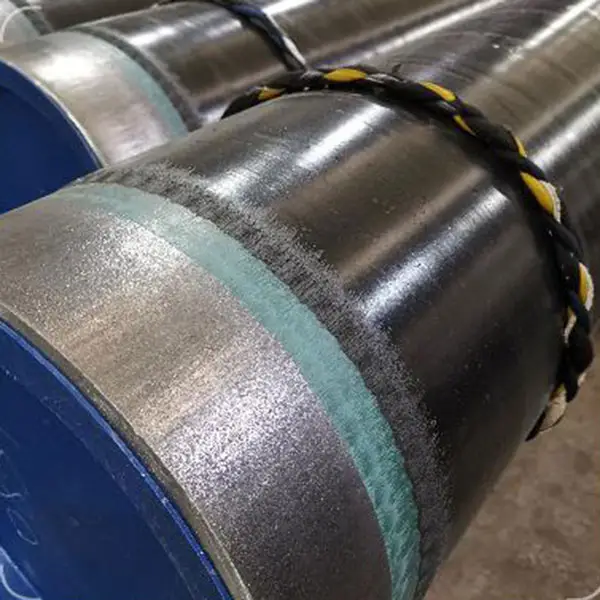

2LPE/3LPE corrosion coating:

2PE/3PE corrosion structure: the steel surface electrostatic spraying epoxy powder and binder twine lateral lateral wound polyethylene coating,combined with three excellent performance,thereby significantly improving the overall quality of corrosion of the pipe. Resistant to chemical corrosion, cathodic stripping, resistance to mechanical damage performance.

Three-layer polyethylene anti-corrosion (3LPE/3PE coating pipe)is currently at home and abroad buried pipe outside the main technical system of anti-corrosion. Its anti-corrosion performance is good, low water absorption, high mechanical strength, in recent years in the domestic buried water, gas, oil pipeline on the access to a wider range of applications.

Steel Pipe material could be coated with external 3LPE coating

|

3LPE Stainless steel pipe |

ASTM A312, ASTM A269 SS Pipe |

|

3LPE Carbon steel pipe |

· ASTM A53 pipe (Grade B) · ASTM A106 pipe (Grade B/C) · ASTM A252 pipe · ASTM A134 and A135 · ASTM A333 (Grade 3/6) |

|

3LPE API 5L Pipe |

· API 5L line pipe · API 5L Grade B · API 5L X42/ X52/ X65/ X80, PSL1/ PSL2 |

|

3LPE Alloy steel pipe |

ASTM A335 P5 to P91 |

|

3LPE Nickel Alloy pipes |

ASTM B161, ASTM B622, ASTM B444 |

|

3LPE CRA clad / lined pipes |

|

THICKNESS OF FBE COATING ON STEEL PIPES

(1)Internal FBE coating

|

Nominal Diameter of Steel Pipe (DN) |

Min Thickness of Anti-Corrosion Layer (μm) |

|

(mm) |

|

|

100-500 |

>350 |

|

500≤DN<750 |

>400 |

|

≥800 |

>450 |

(2)External FBE coating:

|

DN (mm) |

Epoxy Powder (μm) |

Adhesive Layer (μm) |

Min. Thickness on The Coating (mm) |

|

|

Common Level (G) |

Strengthen Level (S) |

|||

|

DN ≤ 100 |

≥120 |

≥170 |

1.8 |

2.5 |

|

100 < DN ≤250 |

2.0 |

2.7 |

||

|

250 < DN < 500 |

2.2 |

2.9 |

||

|

500 ≤DN < 800 |

2.5 |

3.2 |

||

|

DN ≥ 800 |

3.0 |

3.7 |

||

THICKNESS OF 2LPE/3LPE COATING ON STEEL PIPES

1.THICKNESS OF 3LPE COATING ON STEEL PIPES

2.minimum 125 µm Epoxy layer thickness

3.minimum 150 µm copolymer layer thickness

4.inimum thickness of 1.8 mm to 4.7 mm polyethylene or polypropylene layer

Minimum total layer thickness range

|

M kg/m |

Layer thickness in mm |

||||||||

|

Class A1 |

Class A2 |

Class A3 |

Class B1 |

Class B2 |

Class B3 |

Class C1 |

Class C2 |

Class C3 |

|

|

M ≤ 15 |

1,8 |

2,1 |

2,6 |

1,3 |

1,8 |

2,3 |

1,3 |

1,7 |

2,1 |

|

15 < M ≤ 50 |

2,0 |

2,4 |

3,0 |

1,5 |

2,1 |

2,7 |

1,5 |

1,9 |

2,4 |

|

50 < M ≤ 130 |

2,4 |

2,8 |

3,5 |

1,8 |

2,5 |

3,1 |

1,8 |

2,3 |

2,8 |

|

130 < M ≤ 300 |

2,6 |

3,2 |

3,9 |

2,2 |

2,8 |

3,5 |

2,2 |

2,5 |

3,2 |

|

300 < M |

3,2 |

3,8 |

4,7 |

2,5 |

3,3 |

4,2 |

2,5 |

3,0 |

3,8 |

|

Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam. |

|||||||||

Minimum thickness of finished coating

|

Pipe Sizes (Specified OD) |

Minimum Coating Thickness Chart (mm) |

|

≤ 10 3 /4” (273.1 mm) |

2.5 |

|

> 12 3 /4” ( 323.9 mm) to ≤ 18” (457 mm) |

2.8 |

|

> 20" (508.0 mm) to ≤ 30" (762 mm) |

3.0 |

|

> 32" (813.0 mm) |

3.3 |

DIN 30670-2012 :Polyethylene Coatings on Steel Pipes and Fittings

ISO 21809-1:2011: Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems -- Part 1: Polyolefin coatings (3-layer PE and 3-layer PP)

CAN CSA Z245.21 :External Polyethylene Coating for Pipe

NFA 49-710 :External Three-Layer Polyethylene Based Coating, Application by Extrusion

SHELL DEP 31.40.30.31-CSPC: External Polyethylene and Polypropylene Coating for Line Pipe

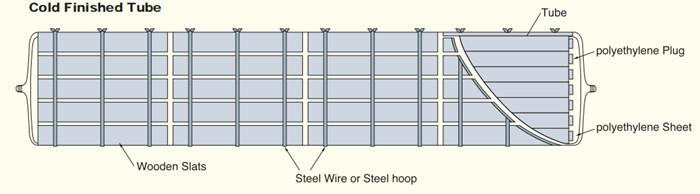

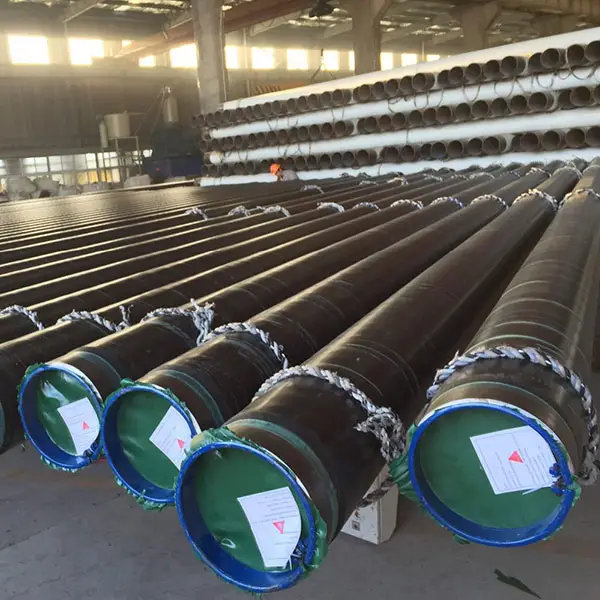

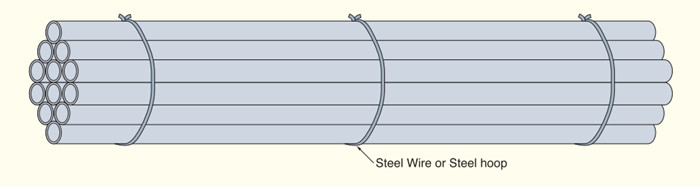

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.