We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

Seamless steel pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

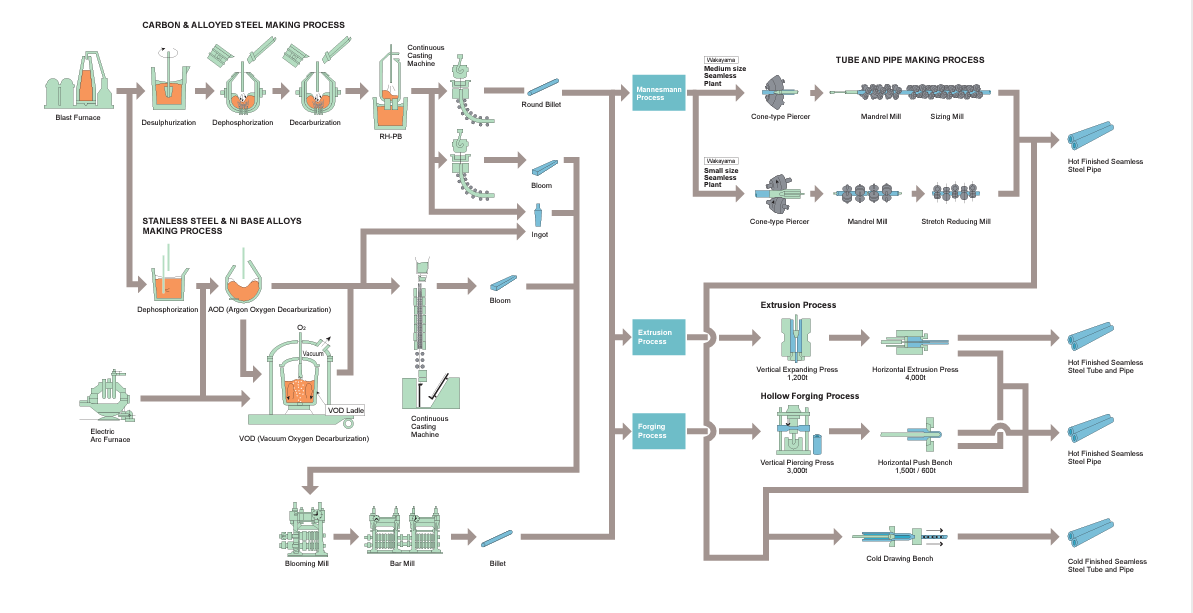

Seamless Pipe (and tubing) is made by extruding a steel block or by drilling a solid steel bar. Next, the extrusion or the drilled steel bar is cold drawn through a dye to achieve the diameter and thickness needed. Because this process can cause mechanical hardening, sometimes the material is annealed and straightened as a final process.

Seamless Pipe & Tubing is subdivided as:

Cold Drawn Seamless, or CDS, exhibits precise tolerances and a good surface finish.

Hot Finished Seamless, or HFS, has less critical tolerances and somewhat scaly finish and is not as strong as CDS.

For Drawn over Mandrel, or DOM tubing, the first stages of manufacturing are identical to ones used to make electric resistance welded tubing, but in the finishing stages the entire flash weld is taken out and the tube is cold drawn over a mandrel. A mandrel is a round object against which material can be forged or shaped. The cold drawn process provides the tube with better dimensional tolerances, improved surface finish and the strongest weld strength achievable.

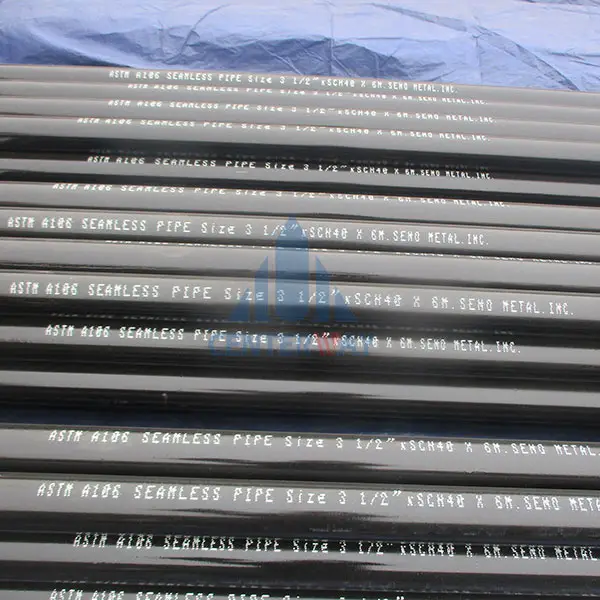

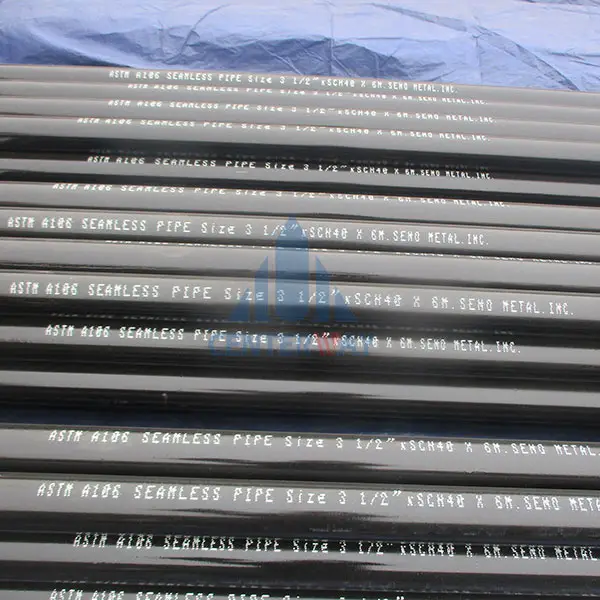

1. Production technology: Hot-rolled and cold drawn

2. Executive standards: API5L , ASME B36.10, ASTM A106/A53

3.Specification range:

OD: OD: 1/8 – 30 inch (10.3-762mm), WT: 0.049”- 2.5” (1.24- 63.5mm)

WT: SCH10-SCHXXS

4. Materials: GrB, Q345B, X42-70, ST44, ST52 etc.

5. Testing: Eddy current/ Hydrostatic/Ultrasonic/ Intergranular Corrosion etc.

6. Packing: Bundles, seaworthy packing, or as required by customers.

7. Application:

API seamless pipe are widely used for petroleum, power generation, natural gas, coal gas, water and some solid materials, also ship-building, chemical fertilizer equipment etc.

|

OD/mm |

WT/mm |

|||||||||||||||||||||||||||||||||||||

|

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

31 |

32 |

33 |

34 |

35 |

36 |

37 |

38 |

39 |

40 |

|

|

21.3 |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26.7 |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

33.4 |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

48.3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60.3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

73 |

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

88.9 |

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

114.3 |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

168.3 |

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

219.1 |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

273.1 |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

323.3 |

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

355.6 |

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

406.4 |

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

457.2 |

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

508 |

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

609.6 |

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

660.4 |

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

711.2 |

|

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

762 |

|

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

Chemical Analysis

|

Standard |

Type of pipe |

Class |

Grade |

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

|

max |

max |

max |

max |

max |

max |

max |

max |

||||

|

API SPEC 5L |

SMLS |

PLS1 |

L245 B L290 X42 L320 X46 L360 X52 L390 X56 L415 X60 L450 X65 L485 X70 L245N BN |

0.28 0.28 0.28 0.28 0.28 0.28 0.28 0.28 0.24 |

0.4 |

1.20 1.30 1.40 1.40 1.40 1.40 1.40 1.40 1.20 |

0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.025 |

0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.015 |

--------- |

--------- |

0.04 |

|

PLS2 |

L290N X42N |

0.24 |

0.4 |

1.2 |

0.025 |

0.015 |

0.06 |

0.05 |

0.04 |

||

|

L320N X46N |

0.24 |

0.4 |

1.4 |

0.025 |

0.015 |

0.07 |

0.05 |

0.04 |

|||

|

L360N X52N |

0.24 |

0.45 |

1.4 |

0.025 |

0.015 |

0.1 |

0.05 |

0.04 |

|||

|

L390N X56N |

0.24 |

0.45 |

1.4 |

0.025 |

0.015 |

0.1 |

0.05 |

0.04 |

|||

|

L415N X60N |

0.24 |

0.45 |

1.4 |

0.025 |

0.015 |

0.1 |

0.05 |

0.04 |

|||

|

WELD |

PLS1 |

L245 B |

0.26 |

- |

1.2 |

- |

0.03 |

0.03 |

- |

- |

|

|

L290 X42 |

0.26 |

- |

1.3 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L320 X46 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L360 X52 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L390 X56 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L415 X60 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L450 X65 |

0.26 |

- |

1.45 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L485 X70 |

0.26 |

- |

1.65 |

- |

0.03 |

0.03 |

- |

- |

|||

|

PLS2 |

L245M BM |

0.22 |

0.45 |

1.2 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

||

|

L290M X42M |

0.22 |

0.45 |

1.3 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

|||

|

L320M X46M |

0.22 |

0.45 |

1.3 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

|||

|

L360M X52M |

0.22 |

0.45 |

1.4 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L390M X56M |

0.22 |

0.45 |

1.4 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L415M X60M |

0.12 |

0.45 |

1.6 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L450M X65M |

0.12 |

0.45 |

1.6 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L485M X70M |

0.12 |

0.45 |

1.7 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L555M X80M |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

- |

- |

- |

|

Standard |

Class |

Grade |

|

Yield strength not less than (MPa) |

Tensile strength (MPa) |

Elongation(%) |

Y.S/T.S |

|

API SPEC 5L ISO 3183 |

PLS1 |

L245B |

min |

245 |

415 |

b |

- |

|

L290X42 |

min |

290 |

415 |

b |

- |

||

|

L320X46 |

min |

320 |

435 |

b |

- |

||

|

L360X52 |

min |

360 |

460 |

b |

- |

||

|

L390X56 |

min |

390 |

490 |

b |

- |

||

|

L415X60 |

min |

415 |

520 |

b |

- |

||

|

L450X60 |

min |

450 |

535 |

b |

- |

||

|

L485X70 |

min |

485 |

570 |

b |

- |

||

|

PLS2 |

L245N BN |

min |

245 |

415 |

b |

- |

|

|

L245M BM |

max |

450 |

760 |

b |

0.93 |

||

|

L290NX42N |

min |

290 |

415 |

b |

- |

||

|

L290MX42M |

max |

495 |

760 |

b |

0.93 |

||

|

L320NX46N |

min |

320 |

435 |

b |

- |

||

|

L320MX46M |

max |

525 |

760 |

b |

0.93 |

||

|

L360NX52N |

min |

360 |

460 |

b |

- |

||

|

L360MX52M |

max |

530 |

760 |

b |

0.93 |

||

|

L390NX56N |

min |

390 |

490 |

b |

- |

||

|

L390MX56M |

max |

545 |

760 |

b |

0.93 |

||

|

L415NX60N |

min |

415 |

520 |

b |

- |

||

|

L415MX60M |

max |

565 |

760 |

b |

0.93 |

||

|

L450MX65M |

min |

450 |

535 |

b |

- |

||

|

max |

600 |

760 |

b |

0.93 |

|||

|

L485MX70M |

min |

485 |

570 |

b |

- |

||

|

max |

635 |

760 |

b |

0.93 |

|||

|

L555MX80M |

min |

555 |

625 |

b |

- |

||

|

max |

705 |

825 |

b |

0.93 |

|

Standard |

Grade |

Transverse minimum impact of Pipe body |

Transverse minimum impact of weld (J) |

|||||

|

(J) |

||||||||

|

D=508 |

508mm |

762mm |

914mm |

1219mm |

D<1422mm |

D=1422mm |

||

|

API SPEC 5L |

=L415X60 |

27(20) |

27(20) |

40(30) |

40(30) |

40(30) |

27(20) |

40(30) |

|

>L415X60 |

27(20) |

27(20) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

|

=L415X65 |

||||||||

|

>L450X65 |

27(20) |

27(20) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

|

=L485X70 |

||||||||

|

>L485X70 =L485X80 |

40(30) |

40(30) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

Seamless line pipe

For its different manufacturing process, there’re hot rolling steel tube and cold drawn seamless steel tube. Agico sells seamless line pipe available in different sizes, weights and grades, customer can choose from black line pipe and galvanized line pipe. from 2-3/8" to 24", steel grade A, B, X42 - X80.

Welded line pipe

Oil and gas welded line pipe for intra-field is used to transport crude oil and natural gas from the field to oil refineries and storage facilities, as well as to shipment points and distribution nodes.

Packing

Package of carbon steel seamless pipe

Plastic caps plugged at the two sides of pipe ends

Should be avoided by the steel strapping and transport damage

Bundled signs should be uniform and consistent

The same bundle(batch) of steel pipe should be came from the same furnace.

The steel pipe has the same furnace number, the same steel grade, the same specifications.