We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

Alloy steel pipe is a kind of seamless steel pipe, its performance is much higher than the general seamless steel pipe, because this steel pipe inside containing Cr, high temperature resistance, low temperature, corrosion-resistant performance of other non-pipe joints not match, so the more extensive use of alloy tube in the petroleum, aerospace, chemical, electric power, boiler, military, and other industries.

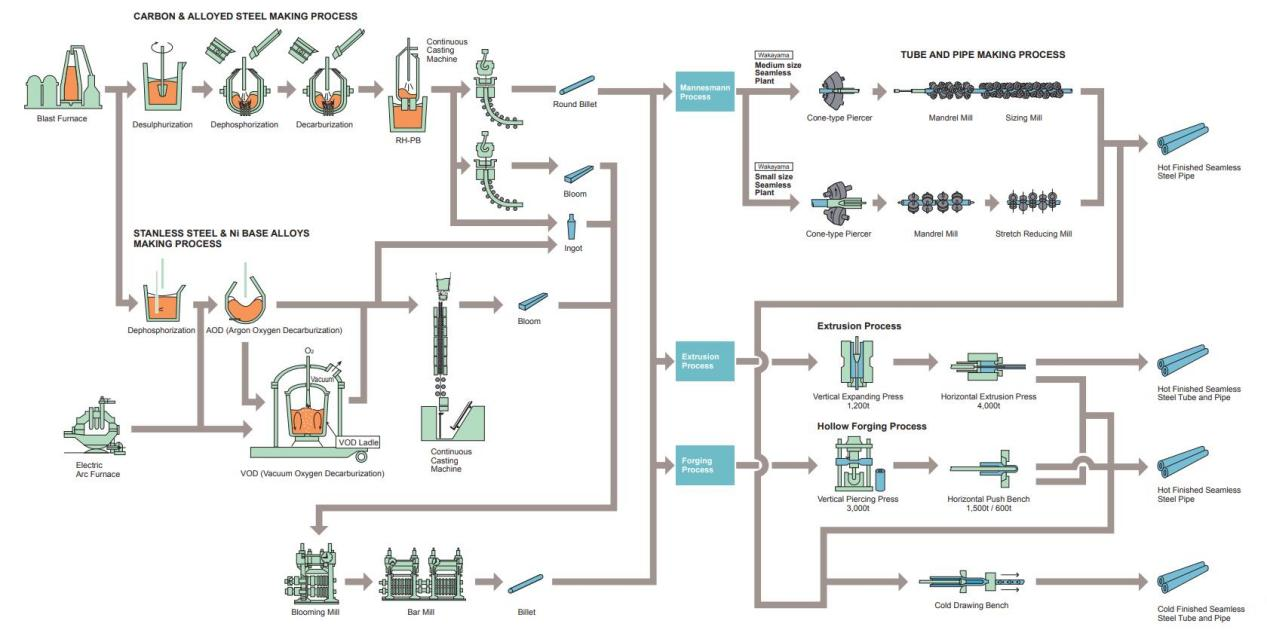

The alloy steel pipe adopts high quality carbon steel, alloy structural steel and stainless & heat resisting steel as raw material through hot rolling or cold drawn to be made.

Alloy steel is a series of alloy which its main content is steel. To add different metal elements with different ratios in steel can change the mechanical properties of alloy steel.

Alloy steel pipes are ideally suitable for chemical, petrochemicals, and other energy-related applications.

The alloy steel pipe adopts high quality carbon steel, alloy structural steel and stainless & heat resisting steel as raw material through hot rolling or cold drawn to be made.

Application

Alloy steel seamless pipe is ideally suitable for chemical, petrochemicals and other energy-related applications. It has characteristics of high corrosion resistance and can be used in a wide range of industrial sectors.

- Chemical industries

- Petrochemical industries

- Energy-related applications

|

Size Range |

1/8" –42” |

|

Schedules |

20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

|

Standard |

ASTM A335, ASTM A213 etc |

|

Grade |

ASTM A335 P1, P2, P5, P9, P11, P12, P22, P23, P91, P92, ASTM A213 T2, T5, T5b, T5c, T9, T11, T12, T22, T23, T91, T92 |

|

ASTM /ASME |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic and Austentic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

ASTM A213 |

Ø10.3~426 x WT1.0~36 |

T5, T9, T11, T12, T22, T91 |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

ASTM A335 |

Ø1/4"~42" x WT2~120mm |

P5, P9, P11, P12, P22, P91, P92 |

|

Seamless Carbon and Alloy Steel for Mechanical Tubing |

ASTM A519 |

Ø16"~42" x WT10~100mm |

4130, 4130X, 4140 |

|

EN |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

EN10216-2 |

Ø8"~42" x WT15~100 |

13CrMo4-5, 1-CrMo9-10, X10CrMoVNb9-1, 15NiCuMoNb5-6-4 |

Hot rolled

Outside Diameter, mm

Tolerance, mm

OD≤101.6

+0.4/-0.8

101.6<OD≤190.5

+0.4/-1.2

190.5<OD≤228.6

+0.4/-1.6

Cold Drawn

Outside Diameter, mm

Tolerance, mm

OD<25.4

±0.10

25.4≤OD≤38.1

±0.15

38.1<OD<50.8

±0.20

50.8≤OD<63.5

±0.25

63.5≤OD<76.2

±0.30

76.2≤OD≤101.6

±0.38

101.6<OD≤190.5

+0.38/-0.64

190.5<OD≤228.6

+0.38/-1.14

Wall thickness & Tolerance

|

Hot rolled |

Outside Diameter, mm |

Tolerance, % |

|

OD≤101.6, WT≤2.4 |

+40/-0 |

|

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD>101.6, WT>4.6 |

+28/-0 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, % |

|

OD≤38.1 |

+20/-0 |

|

|

OD>38.1 |

+22/-0 |

Chemical Composition

|

Grade |

UNS |

C= |

Mn |

P= |

S= |

Si= |

Cr |

Mo |

|

P1 |

K11522 |

0.10~ 0.20 |

0.30~ 0.80 |

0.025 |

0.025 |

0.10~ 0.50 |

- |

0.44~ 0.65 |

|

P2 |

K11547 |

0.10~ 0.20 |

0.30~ 0.61 |

0.025 |

0.025 |

0.10~ 0.30 |

0.50~ 0.81 |

0.44~ 0.65 |

|

P5 |

K41545 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P5b |

K51545 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

1.00~ 2.00 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P5c |

K41245 |

0.12 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P9 |

S50400 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.50~ 1.00 |

8.00~ 10.00 |

0.44~ 0.65 |

|

P11 |

K11597 |

0.05~ 0.15 |

0.30~ 0.61 |

0.025 |

0.025 |

0.50~ 1.00 |

1.00~ 1.50 |

0.44~ 0.65 |

|

P12 |

K11562 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

0.80~ 1.25 |

0.44~ 0.65 |

|

P15 |

K11578 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

1.15~ 1.65 |

- |

0.44~ 0.65 |

|

P21 |

K31545 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

2.65~ 3.35 |

0.80~ 1.60 |

|

P22 |

K21590 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

1.90~ 2.60 |

0.87~ 1.13 |

|

P91 |

K91560 |

0.08~ 0.12 |

0.30~ |

0.02 |

0.01 |

0.20~ 0.50 |

8.00~ 9.50 |

0.85~ 1.05 |

|

0.6 |

||||||||

|

P92 |

K92460 |

0.07~ 0.13 |

0.30~ 0.60 |

0.02 |

0.01 |

0.5 |

8.50~ 9.50 |

0.30~ 0.60 |

|

Tensile Strength, MPa |

Yield Strength, MPa |

Elongation, % |

|

415 min |

205 min |

30 min |

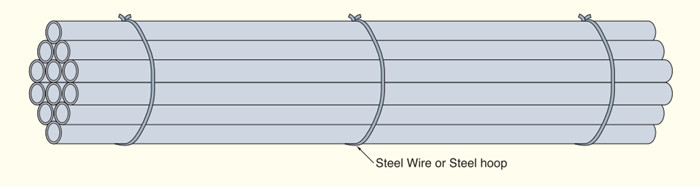

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below

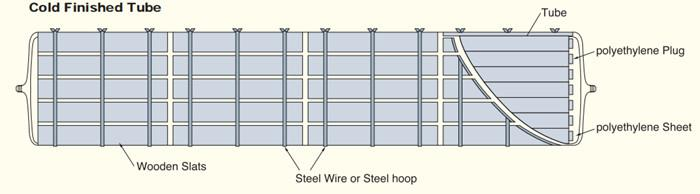

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.