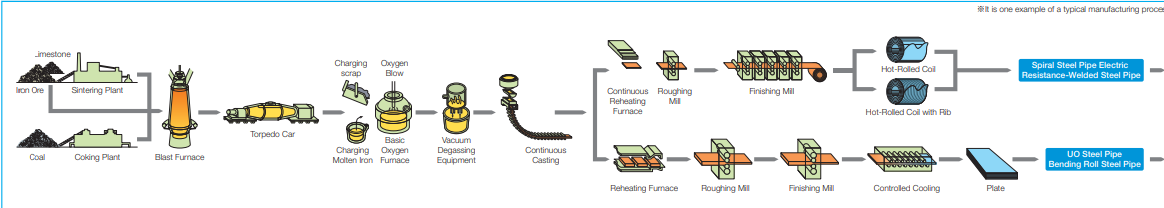

We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

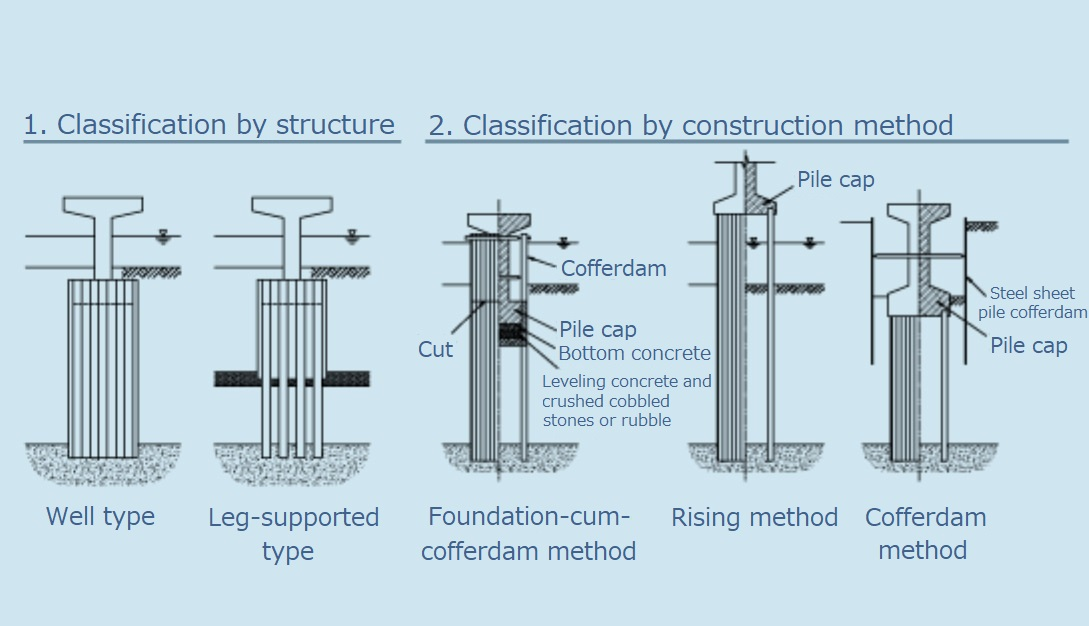

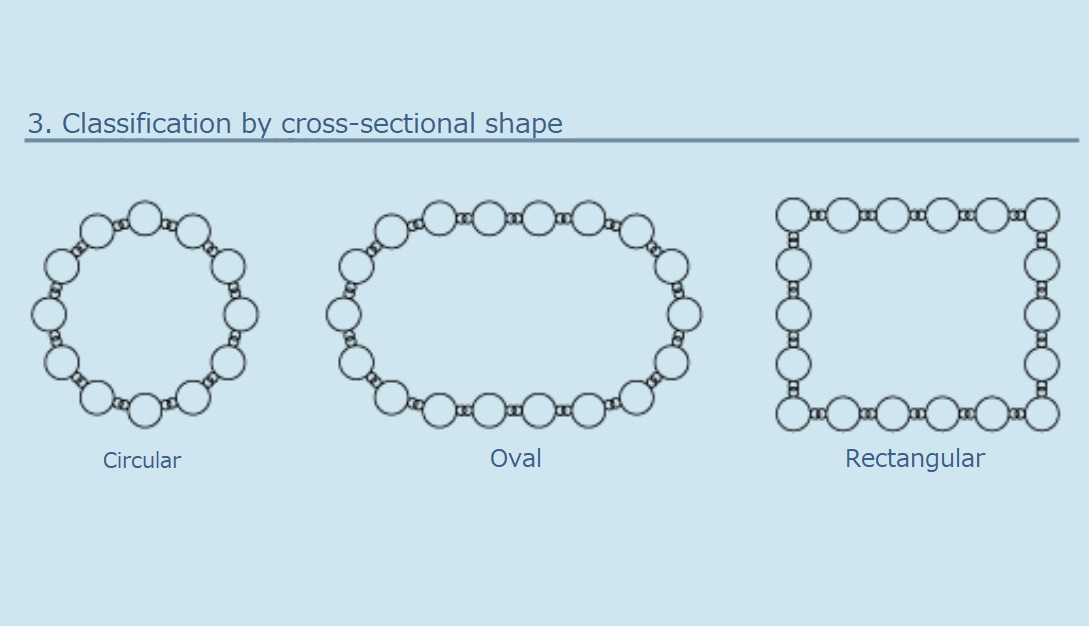

Steel pipe sheet piles, which consist of steel pipes with joints welded onto them, are widely used as retaining walls and as riverside and harbor revetments. Steel pipe sheet piles can be used to make a circular, oval or rectangular shaped well foundation which combines the functions of foundation piles and a cofferdam, realizing efficient and economical design and construction processes. Having large cross-section properties, steel pipe sheet piles can realize compact foundation designs that minimize interference with river flows.

Advantages

Lateral Resistance Larger than that of Steel Sheet Piles

Since steel pipe sheet piles have greater lateral resistance than that of steel sheet piles, it is easy to construct large wall structures or free-standing walls without tie rods.

Can Function as Both Wall and Foundation Pile

Being capable of withstanding not only lateral loads but also large vertical loads, steel pipe sheet piles can combine the functions of sheet pile walls and foundation piles.

Sheet Piles Can be Joined into any Shape

Steel pipe sheet piles can be shaped freely by changing joint positions, whether into a curved line or straight line.

Joint Shape Varieties for Different Applications

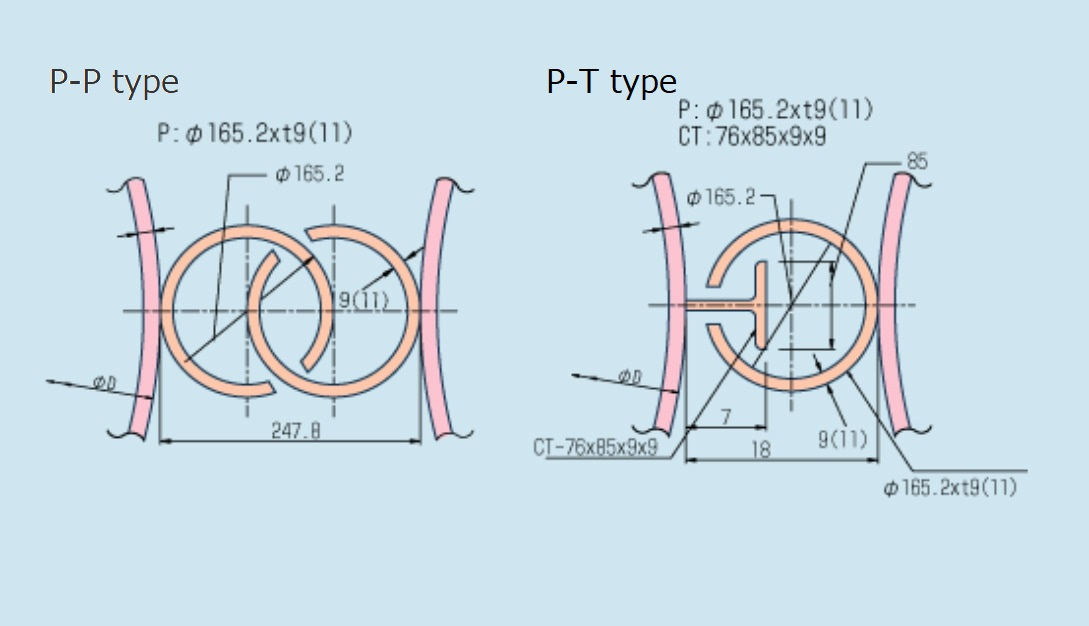

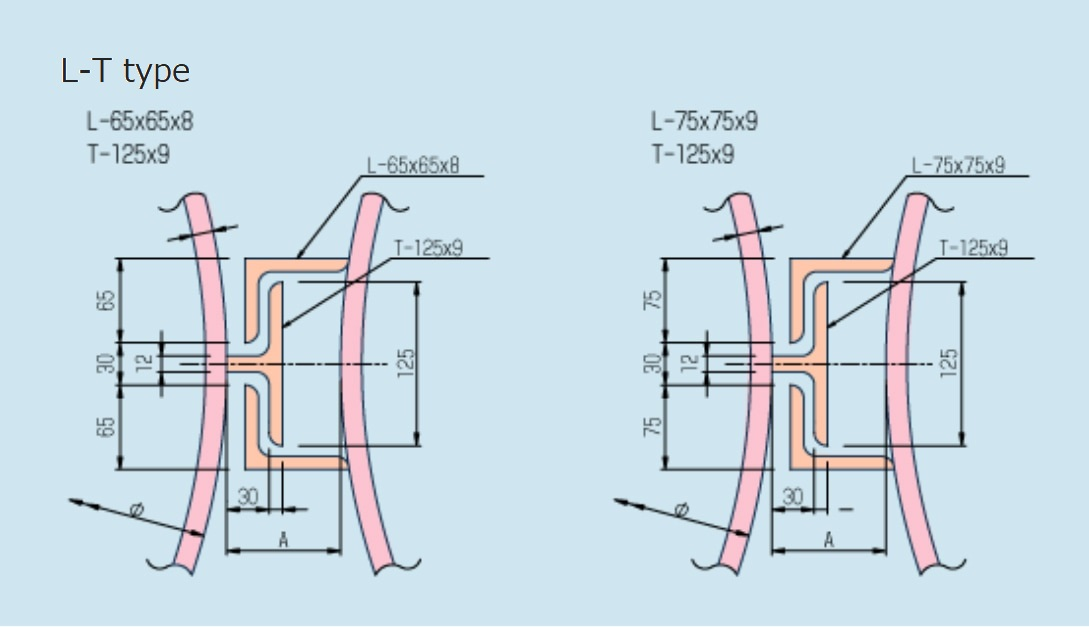

Steel pipe sheet pile joints are available in three types: P-P, L-T and P-T. You can choose joint designs to suit your applications, whether for revetment structures, bridge foundations, cofferdam walls or retaining walls. The P-P type, in particular, can deliver superior cut-off performance through use of a waterstop treatment.

They also offer all of the advantages of steel pipe piles in addition to the above-mentioned ones.

Applications

Revetments, Quay Walls, etc.

Inner breakwaters, closing levees, cut-off walls, cofferdams, retaining walls, pipe-roofs, etc.

Steel Pipe Sheet Pile Foundations

Bridge pier foundations, abutment foundations, etc.

Types of Steel Pipe Sheet Pile Foundations

Steel pipe sheet pile foundations are broadly classified into the following types by structure , construction method and cross-sectional shape.

Three types of joint designs are available, as shown below. Select the most appropriate type for your application and purpose.

ASTM A252--This specification is generally for the wall steel pipes that are cylindrical in shape and the steel cylinder acts like a load-carrying member for the cast-in-place piles of concrete.Grades in three levels, Gr 1, Gr 2, and Gr 3.

STEEL CHEMICAL COMPOSITION

The steel shall conform to the following requirements as to chemical composition:

Phosphorus, maximum (%) : 0.050

MECHANICAL PROPERTIES

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

|

GRADE 1 |

30,000 (205) |

50,000 (345) |

30% |

|

GRADE 2 |

35,000 (240) |

60,000 (415) |

25% |

|

GRADE 3 |

45,000 (310) |

66,000 (455) |

20% |

TEST REQUIRED

Chemical Analysis, Mechanical Test, Visusal Inspection , Tension Test, Dimension Check

EN10219 Structure Pipe

STEEL GRADE

EN10219 S235, S275, S355,etc

STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

% by mass, Maximum |

|||||

|

C |

Si |

Mn |

P |

S |

N |

|

|

S235JRH |

0.17 |

– |

1.40 |

0.040 |

0.040 |

0.009 |

|

S275JOH |

0.20 |

– |

1.50 |

0.035 |

0.035 |

0.009 |

|

S275J2H |

0.20 |

– |

1.50 |

0.030 |

0.030 |

– |

|

S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

0.009 |

|

S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

– |

|

S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

– |

MECHANICAL PROPERTIES

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

Minimum Impact energy KV J |

||

|

at test temperature of |

||||||

|

-20 |

0 |

20 |

||||

|

S235JRH |

235 |

360 |

24% |

– |

– |

27 |

|

S275JOH |

275 |

430 |

20% |

– |

27 |

– |

|

S275J2H |

355 |

510 |

20% |

27 |

– |

– |

|

S355JOH |

355 |

510 |

20% |

– |

27 |

– |

|

S355J2H |

355 |

510 |

20% |

27 |

– |

– |

|

S355K2H |

355 |

510 |

20% |

40 |

– |

– |

TEST REQUIRED

Chemical Analysis, Mechanical Test, Visusal Inspection , Tensile Test, Dimension Check, NDT ,Impact Test

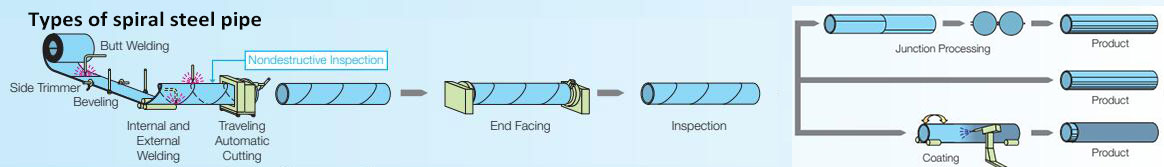

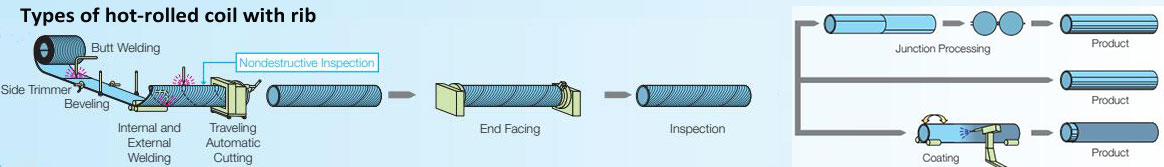

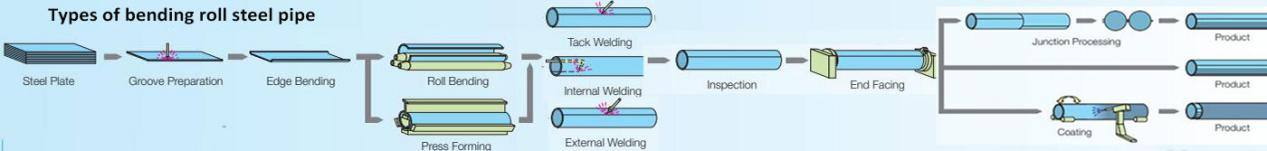

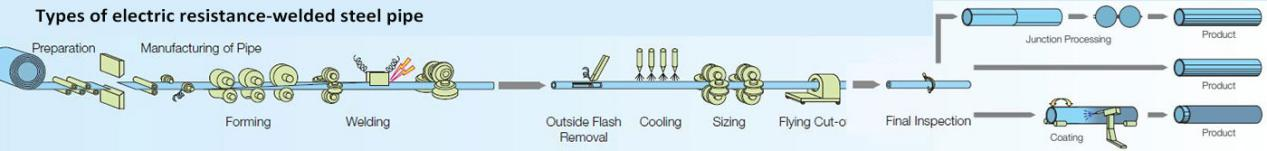

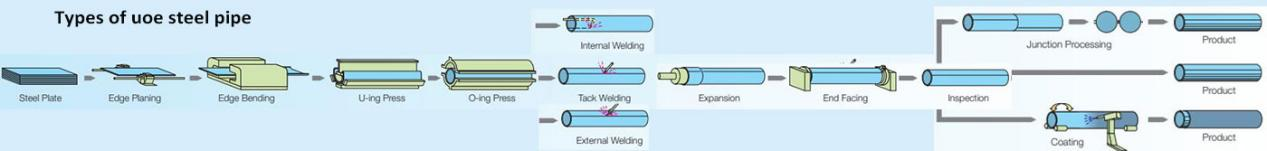

Pipe piling generally manufactured using seamless, resistance welding, fusion welding, flash welding with seams being longitudinal, helical. It also specifies the tensile requirements, minimum values and the common size and weight based on the values.