We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

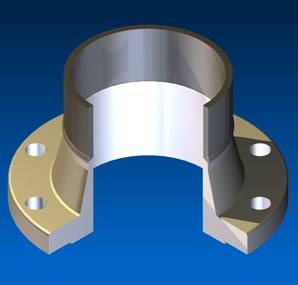

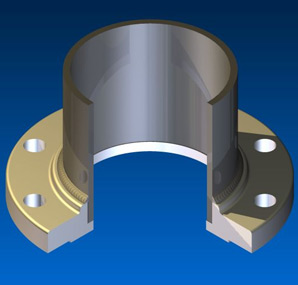

Weld Neck Flange

This flange type is designed to be connected by a butt weld connection to the pipe or equipment requiring a flanged joint. Welding neck provides good service under variety of temperature and pressure applications. A weld neck flange must specifiy the pipe schedule for the bore. Due to the welding neck, it is a popular choice on pressure vessels and for creating man-holes etc. These flanges are also knows as ANSI Flange or ASME B16.5 Flange

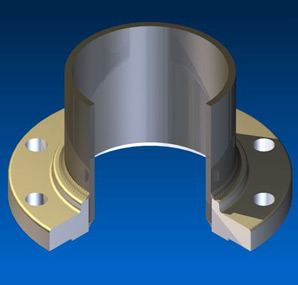

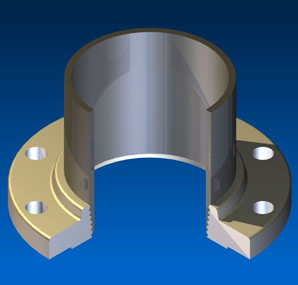

Slip On Flange

A slip on flange is designed to slip over the end of pipe. It allows for easy positioning before welding. Both the inside and outside of the pipe is welded on the slip on flange. The pipe is generally inserted all the way, inside the slip on flange, leaving only the gap equivalent to wall thickness of pipe.

Lap Joint Flange

Lap joint flanges use a stub end that is welded to the pipe. A ring flange fits loosely around the stub end, permitting easy flange alignment of the bolt holes. A lap joint flange is also called Van Stone or Stub Flange. The stub ends are available in three styles (Types A, B, and C) and two lengths (Short and Long).

Threaded Flange

Threaded flange is also called screwed flange or screwed-on flange. This type of flange is used where welding is not an option. Threaded flange is most commonly used on low pressure applications and smaller pipes.

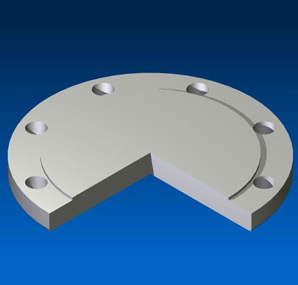

Blind Flange

A blind flange is a solid flange with no bore or threaded hole and is used to close the end of pipe, fittings, valves or equipment. Blind pipe flange is also used for pressure testing equipment. Blind flange comes both as raised face and flat face.

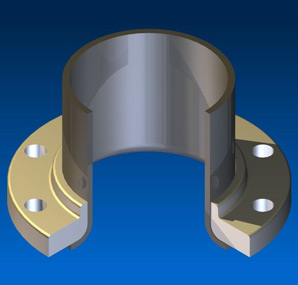

Socket Weld Flange

Socket-weld pipe flanges are typically used on smaller sizes of high-pressure pipes. These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe.

|

No. |

Flange standard |

size |

Pressure rating |

Types |

|

1 |

ANSI / ASME FLANGE B16.5 |

1/2"~24" |

LBS:150,300,400,600,900,1500,2500 |

SO,WN,IF,SW,TH,LF/SE,LWN,BL |

|

2 |

ORIFICE FLANGE B16.36 |

1''~24” |

LBS:300,400,600,900,1500,2500 |

SO,WN,TH |

|

3 |

LONG WELDING NECK FLANGE B16.5 |

1/2"~24" |

LBS:150,300,400,600,900,1500,2500 |

LWN |

|

4 |

ASME B16.47-A (MSS SP44 FLANGE) |

26"-60" |

LBS:150,300,400,600,900 |

WN,BL, |

|

5 |

ASME B16.47-B (API 605 FLANGE ) |

26"-60" |

LBS:75,150,300,400,600,900 |

WN,BL, |

|

6 |

AWWA C207 FLANGE |

4"-120" |

TABLE 2,3,4 CLASS B&D |

SO,BL, |

|

7 |

API 590 FIG.8 FLANGE B16.48 |

1/2"~36" |

LBS:150,300,400,600,900,1500,2500 |

FIG.8 |

|

8 |

SPACER AND BLANK B16.48 |

1/2"~36" |

LBS:150,300,400,600 |

SPACER AND BLANK |

|

9 |

BS4504 FLANGE |

DN10-2000 |

PN:2,5,6,10,16,25,40 |

CODE:101,111,112,113,105 |

|

10 |

SABS 1123 FLANGE |

DN10-600 |

KPA: 600,1000,1600,2500,4000 |

SO,WN,SW,TH,LJ,BL |

|

11 |

JIS B2220(KS B1503) FLANGE |

DN10-1500 |

5K,10K,16K,20K,30K,40K |

SO,WN,SW,TH,LJ,BL, |

|

12 |

GOST 12820/1-80 |

DN15-1200 |

PN:1,1.6,2.5,4,6.3,10 |

SO,WN |

|

13 |

AS 2129 FLANGE |

DN15-1200 |

TABLE:D,E,F,H |

SO,BL, |

|

14 |

NS FLANGE |

DN15-800 |

PN: 6,10,16,40 |

SO,BL, |

|

15 |

VSM FLANGE |

DN15-800 |

PN: 6,10,16 |

|

|

DN |

Dimension |

ANSI B16.5 Flange Dimensional Sizes 1/2 to 2 1/2 inches Table Chart |

|||||||||||||

|

|

|

125 lbs |

300 lbs |

400 lbs |

600 lbs |

900 lbs |

1500 lbs |

2500 lbs |

|||||||

|

|

|

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

|

1/2 |

A |

3 1/2 |

88.9 |

3 3/4 |

95.2 |

3 3/4 |

95.2 |

3 3/4 |

95.2 |

4 3/4 |

121 |

4 3/4 |

121 |

5 1/4 |

133.4 |

|

|

b |

7/16 |

11.1 |

9/16 |

14.3 |

9/16 |

14.3 |

9/16 |

14.3 |

7/8 |

22.2 |

7/8 |

22.2 |

1 3/16 |

30.2 |

|

|

D2 |

1 3/8 |

34.9 |

1 3/8 |

34.9 |

1 3/8 |

34.9 |

1 3/8 |

34.9 |

1 3/8 |

34.9 |

1 3/8 |

34.9 |

1 3/8 |

34.9 |

|

|

D1 |

2 3/8 |

60.3 |

2 5/8 |

66.7 |

2 5/8 |

66.7 |

2 5/8 |

66.7 |

3 1/4 |

82.6 |

3 1/4 |

82.6 |

3 1/2 |

88.9 |

|

|

n |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

- |

4 |

44 |

|

|

d |

5/8 |

15.9 |

5/8 |

15.9 |

5/8 |

15.9 |

5/8 |

15.9 |

7/8 |

22.2 |

7/8 |

22.2 |

7/8 |

22.2 |

|

3/4 |

A |

3 7/8 |

98.4 |

4 5/8 |

117.5 |

4 5/8 |

117.5 |

4 5/8 |

117.5 |

5 1/8 |

130 |

5 1/8 |

130 |

5 1/2 |

139.7 |

|

|

b |

1/2 |

12.7 |

5/8 |

15.9 |

5/8 |

15.9 |

5/8 |

15.9 |

1 |

25.4 |

1 |

25.4 |

1 1/4 |

31.8 |

|

|

D2 |

1 11/16 |

42.9 |

1 11/16 |

42.9 |

1 11/16 |

42.9 |

1 11/16 |

42.9 |

1 11/16 |

42.9 |

1 11/16 |

42.9 |

1 11/16 |

42.9 |

|

|

D1 |

2 3/4 |

69.8 |

3 1/4 |

82.5 |

3 1/4 |

82.5 |

3 1/4 |

82.5 |

3 1/2 |

88.9 |

3 1/2 |

88.9 |

3 3/4 |

95.2 |

|

|

n |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

- |

4 |

44 |

|

|

d |

5/8 |

15.9 |

3/4 |

19 |

3/4 |

19 |

3/4 |

19 |

7/8 |

22.2 |

7/8 |

22.2 |

7/8 |

22.2 |

|

1 |

A |

4 1/4 |

108 |

4 7/8 |

123.8 |

4 7/8 |

123.8 |

4 7/8 |

123.8 |

5 7/8 |

149.2 |

5 7/8 |

149.2 |

6 1/4 |

159 |

|

|

b |

9/16 |

14.3 |

11/16 |

17.5 |

11/16 |

17.5 |

11/16 |

17.5 |

1 1/8 |

28.6 |

1 1/8 |

28.6 |

1 3/8 |

34.9 |

|

|

D2 |

2 |

50.8 |

2 |

50.8 |

2 |

50.8 |

2 |

50.8 |

2 |

50.8 |

2 |

50.8 |

2 |

50.8 |

|

|

D1 |

3 1/8 |

79.4 |

3 1/2 |

88.9 |

3 1/2 |

88.9 |

3 1/2 |

88.9 |

4 |

102 |

4 |

102 |

4 1/4 |

108 |

|

|

n |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

|

d |

5/8 |

15.9 |

3/4 |

19 |

3/4 |

19 |

3/4 |

19 |

1 |

25.4 |

1 |

25.4 |

1 |

25.4 |

|

1 1/4 |

A |

4 5/8 |

117.5 |

5 1/4 |

133.4 |

5 1/4 |

133.4 |

5 1/4 |

133.4 |

6 1/4 |

159 |

6 1/4 |

159 |

7 1/4 |

184.2 |

|

|

b |

5/8 |

15.9 |

3/4 |

19 |

13/16 |

20.6 |

13/16 |

20.6 |

1 1/8 |

28.6 |

1 1/8 |

28.6 |

1 1/2 |

38.1 |

|

|

D2 |

2 1/2 |

63.5 |

2 1/2 |

63.5 |

2 1/2 |

63.5 |

2 1/2 |

63.5 |

2 1/2 |

63.5 |

2 1/2 |

63.5 |

2 1/2 |

63.5 |

|

|

D1 |

3 1/2 |

88.9 |

3 7/8 |

98.4 |

3 7/8 |

98.4 |

3 7/8 |

98.4 |

4 3/8 |

111 |

4 3/8 |

111 |

5 1/8 |

130 |

|

|

n |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

|

d |

5/8 |

15.9 |

3/4 |

19 |

3/4 |

19 |

3/4 |

19 |

1 |

25.4 |

1 |

25.4 |

1 1/8 |

28.6 |

|

1 1/2 |

A |

5 |

127 |

6 1/8 |

155.6 |

6 1/8 |

155.6 |

6 1/8 |

155.6 |

7 |

177.8 |

7 |

177.8 |

8 |

203 |

|

|

b |

11/16 |

17.5 |

13/16 |

20.6 |

7/8 |

22.2 |

7/8 |

22.2 |

1 1/4 |

31.8 |

1 1/4 |

31.8 |

1 3/4 |

44.5 |

|

|

D2 |

2 7/8 |

73 98 |

2 7/8 |

73 |

2 7/8 |

73 |

2 7/8 |

73 |

2 7/8 |

73 |

2 7/8 |

73 |

2 7/8 |

73 |

|

|

D1 |

3 7/8 |

4 |

4 1/2 |

114 |

4 1/2 |

114 |

4 1/2 |

114 |

4 7/8 |

124 |

4 7/8 |

124 |

5 3/4 |

146 |

|

|

n |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

|

d |

5/8 |

. 15.9 |

7/8 |

22.2 |

7/8 |

22.2 |

7/8 |

22.2 |

1 1/8 |

28.6 |

1 1/8 |

28.6 |

1 1/4 |

31.8 |

|

2 |

A |

6 |

152.4 |

6 1/2 |

165.1 |

6 1/2 |

165.1 |

6 1/2 |

165.1 |

8 1/2 |

215.9 |

8 1/2 |

215.9 |

9 1/4 |

234.9 |

|

|

b |

3/4 |

19 |

7/8 |

22.2 |

1 |

25.4 |

1 |

25.4 |

1 1/2 |

38.1 |

1 1/2 |

38.1 |

2 |

50.8 |

|

|

D2 |

3 5/8 |

92.1 |

3 5/8 |

92.1 |

3 5/8 |

92.1 |

3 5/8 |

92.1 |

3 5/8 |

92.1 |

3 5/8 |

92.1 |

3 5/8 |

92.1 |

|

|

D1 |

4 3/4 |

121 |

5 |

127 |

5 |

127 |

5 |

127 |

6 1/2 |

165.1 |

6 1/2 |

165.1 |

6 3/4 |

171 |

|

|

n |

4 |

4 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

|

|

d |

3/4 |

19 |

3/4 |

19 |

3/4 |

19 |

3/4 |

19 |

1 |

25.4 |

1 |

25.4 |

1 1/8 |

28.6 |

|

2 1/2 |

A |

7 |

177.8 |

7 1/2 |

190.5 |

7 1/2 |

190.5 |

7 1/2 |

190.5 |

9 5/8 |

244 |

9 5/8 |

244 |

10 1/2 |

266.7 |

|

|

b |

7/8 |

22.2 |

1 |

25.4 |

1 1/8 |

28.6 |

1 1/8 |

28.6 |

1 5/8 |

41.3 |

1 5/8 |

41.3 |

2 1/4 |

57.2 |

|

|

D2 |

4 1/8 |

104.8 |

4 1/8 |

104.8 |

4 1/8 |

104.8 |

4 1/8 |

104.8 |

4 1/8 |

105 |

4 1/8 |

105 |

4 1/8 |

105 |

|

|

D1 |

5 1/2 |

139.7 |

5 7/8 |

149.2 |

5 7/8 |

149.2 |

5 7/8 |

149.2 |

7 1/2 |

190.5 |

7 1/2 |

190.5 |

7 3/4 |

197 |

|

|

n |

4 |

4 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

|

|

d |

3/4 |

19 |

7/8 |

22.2 |

7/8 |

22.2 |

7/8 |

22.2 |

1 1/8 |

28.6 |

1 1/8 |

28.6 |

1 1/4 |

31.8 |

|

Standard |

Specification |

|

ASTM A105 |

Standard Specification for Carbon Steel Forgings for Piping Applications |

|

ASTM A350 |

Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components |

|

ASTM A182 |

Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service |

|

ASTM A404 |

Specification for Forged or Rolled Alloy Steel Pip Flanges, Forged Fittings, and Valves and Parts Specially Heat Treated for High-Temperature Service (Withdrawn 1974) |

|

ASTM A234 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

|

ASTM A420 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

|

ASTM A403 |

Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

|

ASTM A694 |

Standard Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service |