We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

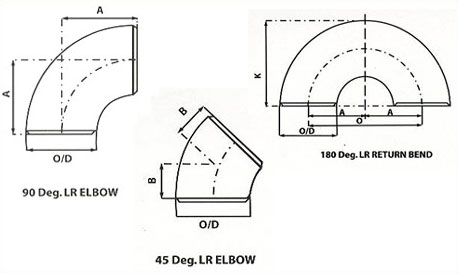

What is Elbow Radius?

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

Classified by Direction Angle

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

45 degree elbow

45 degree elbow of long radius

The pipe elbow is mounted between two pipes so that the fluid direction can be changed to 45 degrees. Compared to 90 degree elbow, 45 degree elbow produces less friction, and with the lower pressure.

45 degree elbow of short radius

SR Elbow in 45 degree is usually attached to copper, plastic, steel, cast iron and lead, and can also be connected to stainless and rubber fixtures. It is widely used in chemical, food, water supply facilities, electronic industry, chemical pipelines, horticulture, agriculture production, solar equipment pipelines, air conditioning pipeline and other fields.

90 degree steel pipe elbow

Long radius 90 degree elbow

LR 90 degree steel pipe elbow are installed between different lengths pipe or tubing. It helps to change direction at 90 degree, and is commonly used to connect hoses to pumps, deck drains and valve.

Short radius 90 degree elbow

SR 90 degree elbow is the same as the pipe elbow mentioned above, but the diameter is shorter. Therefore, this kind of steel elbow is often used when space is not enough.

180 Degree Steel Elbow

180 Degree steel elbow helps change direction at 180 degrees, since it usually results in low pressure. Its application is limited to minimal deposition and low turbulence system.

|

Nominal pipe size |

Outside Diameter |

Center to End |

Center to Center |

Back to Faces |

||||||

|

45°Elbows |

90°Elbows |

180°Return |

||||||||

|

H |

F |

P |

K |

|||||||

|

DN |

INCH |

Series A |

Series B |

LR |

LR |

SR |

LR |

SR |

LR |

SR |

|

15 |

1/2 |

21.3 |

18 |

16 |

38 |

- |

76 |

- |

48 |

- |

|

20 |

3/4 |

26.9 |

25 |

16 |

38 |

- |

76 |

- |

51 |

- |

|

25 |

1 |

33.7 |

32 |

16 |

38 |

25 |

76 |

51 |

56 |

41 |

|

32 |

11/4 |

42.4 |

38 |

20 |

48 |

32 |

95 |

64 |

70 |

52 |

|

40 |

11/2 |

48.3 |

45 |

24 |

57 |

38 |

114 |

76 |

83 |

62 |

|

50 |

2 |

60.3 |

57 |

32 |

76 |

51 |

152 |

102 |

106 |

81 |

|

65 |

21/2 |

76.1(73) |

76 |

40 |

95 |

64 |

191 |

127 |

132 |

100 |

|

80 |

3 |

88.9 |

89 |

47 |

114 |

76 |

229 |

152 |

159 |

121 |

|

90 |

31/2 |

101.6 |

- |

55 |

133 |

89 |

267 |

178 |

184 |

140 |

|

100 |

4 |

114.3 |

108 |

63 |

152 |

102 |

305 |

203 |

210 |

159 |

|

125 |

5 |

139.7 |

133 |

79 |

190 |

127 |

381 |

254 |

262 |

197 |

|

150 |

6 |

168.3 |

159 |

95 |

229 |

152 |

457 |

305 |

313 |

237 |

|

200 |

8 |

219.1 |

219 |

126 |

305 |

203 |

610 |

406 |

414 |

313 |

|

250 |

10 |

273.0 |

273 |

158 |

381 |

254 |

762 |

508 |

518 |

391 |

|

300 |

12 |

323.9 |

325 |

189 |

457 |

305 |

914 |

610 |

619 |

467 |

|

350 |

14 |

355.6 |

377 |

221 |

533 |

356 |

1067 |

711 |

711 |

533 |

|

400 |

16 |

406.4 |

426 |

253 |

610 |

406 |

1219 |

813 |

813 |

610 |

|

450 |

18 |

457.2 |

478 |

284 |

686 |

457 |

1372 |

914 |

914 |

686 |

|

500 |

20 |

508.0 |

529 |

316 |

762 |

508 |

1524 |

1016 |

1016 |

762 |

|

550 |

22 |

559 |

- |

347 |

838 |

559 |

Note: |

|||

|

600 |

24 |

610 |

630 |

379 |

914 |

610 |

||||

|

650 |

26 |

660 |

- |

410 |

991 |

660 |

||||

|

700 |

28 |

711 |

720 |

442 |

1067 |

711 |

||||

|

750 |

30 |

762 |

- |

473 |

1143 |

762 |

||||

|

800 |

32 |

813 |

820 |

505 |

1219 |

813 |

||||

|

850 |

34 |

864 |

- |

537 |

1295 |

864 |

||||

|

900 |

36 |

914 |

920 |

568 |

1372 |

914 |

||||

|

950 |

38 |

965 |

- |

600 |

1448 |

965 |

||||

|

1000 |

40 |

1016 |

1020 |

631 |

1524 |

1016 |

||||

|

1050 |

42 |

1067 |

- |

663 |

1600 |

1067 |

||||

|

1100 |

44 |

1118 |

1120 |

694 |

1676 |

1118 |

||||

|

1150 |

46 |

1168 |

- |

726 |

1753 |

1168 |

||||

|

1200 |

48 |

1220 |

1220 |

758 |

1829 |

1219 |

||||

ASTM A234 WPB, ASME B16.9,MSS SP-43,DIN 2617,JIS B2313 ,GB/T12459,GB/T13401,SH3408,SH3409,HG/T21635,HG/T21631

Materials:

Carbon Steel:ASTM A234 WPB WPC A105 A106 A53 A283-D API5LB A671-CC-70 A515-50 A135-A A179-C,etc

Stainless Steel:304/304L, 316/316L,316Ti,321,317L,310S,etc

Alloy Steel:A335-P1,P2 ,P5 ,P11,P12 ,P22,P91,P92,A369-FP1,P2 A250-T1 A209-T1 A213-T2,T9 ,T12 A199-T11,T22,

Duplex Stainless Steel: S31803(SAF2205),S32750(SAF2507),S31500(3RE60)

|

ASTM A234 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

|

ASTM A420 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

|

ASTM A403 |

Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

|

ASME B16.9 |

Factory Made Wroght Steel Butt Welding Fittings |

ASTM A234

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

Cr |

Mo |

Ni |

Al |

Nb |

N |

Others |

|

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

||

|

A234 |

WPC |

0.28 |

- |

1.20 |

0.030 |

0.030 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

WPB |

0.28 |

- |

1.20 |

0.030 |

0.030 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

WP11 |

0.05-0.15 |

0.50-1.0 |

0.30-0.60 |

0.025 |

0.025 |

- |

- |

- |

1.00-1.50 |

0.44–0.65 |

- |

- |

- |

- |

- |

|

|

WP22 |

0.05-0.15 |

0.50 |

0.30-0.60 |

0.025 |

0.025 |

- |

- |

- |

1.90-2.60 |

0.87–1.13 |

- |

- |

- |

- |

- |

|

|

WP5 |

0.15 |

0.50 |

0.30-0.60 |

0.025 |

0.025 |

- |

- |

- |

4.00-6.00 |

0.45–0.65 |

- |

- |

- |

- |

- |

|

|

WP9 |

0.15 |

0.25-1.0 |

0.30-0.60 |

0.025 |

0.025 |

- |

- |

- |

8.00-10.00 |

0.90–1.10 |

- |

- |

- |

- |

- |

|

|

WP91 |

0.08-0.12 |

0.20-0.50 |

0.30-0.60 |

0.020 |

0.010 |

0.18–0.25 |

- |

- |

8.00-9.50 |

0.85–1.05 |

0.40 |

0.04 |

- |

0.03–0.07 |

Cb |

|

|

WP92 |

0.07-0.13 |

0.5 |

0.30-0.60 |

0.020 |

0.010 |

0.15–0.25 |

- |

- |

8.50-9.50 |

0.30–0.60 |

0.40 |

0.04 |

- |

0.03–0.07 |

Cb |

ASTM A420/A420M

|

Steel No. |

Type |

Chemical composition |

||||||||||||

|

C |

Si |

S |

P |

Mn |

Cr |

Ni |

Mo |

Other |

ób |

ós |

δ5 |

HB |

||

|

WPL6 |

0.3 |

0.15-0.3 |

0.04 |

0.035 |

0.6-1.35 |

0.3 |

0.4 |

0.12 |

Cb:0.02;V:0.08 |

415-585 |

240 |

22 |

|

|

|

WPL9 |

0.2 |

|

0.03 |

0.03 |

0.4-1.06 |

|

1.6-2.24 |

|

|

435-610 |

315 |

20 |

|

|

|

WPL3 |

0.2 |

0.13-0.37 |

0.05 |

0.05 |

0.31-0.64 |

|

3.2-3.8 |

|

|

450-620 |

240 |

22 |

|

|

|

WPL8 |

0.13 |

0.13-0.37 |

0.03 |

0.03 |

0.9 |

|

8.4-9.6 |

|

|

690-865 |

515 |

16 |

|

|