Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

The ASTM A179 seamless steel tube is a low-carbon steel product specifically designed for heat exchangers, condensers, and similar heat transfer equipment. This specification ensures excellent thermal conductivity, high precision in dimensions, and reliable performance under moderate pressure and temperature. Engineers and procurement specialists often choose ASTM A179 tubes because of their superior cold-drawn surface quality and uniform wall thickness.

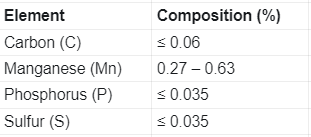

The chemical composition of ASTM A179 tubes emphasizes low carbon content, which enhances ductility and improves cold-forming performance. According to the ASTM standard, the material must meet the following limits:

Low carbon and controlled manganese levels make the ASTM A179 seamless steel tube easy to bend, expand, and weld, which is particularly beneficial in heat exchanger fabrication.

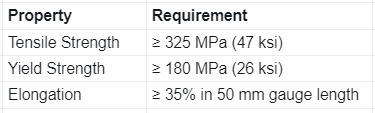

Mechanical properties define the performance of the tube under stress, pressure, and temperature changes. The standard requires the following minimum mechanical values:

These properties ensure the tube can withstand internal pressure and thermal cycling without deformation or cracking. In addition, the cold-drawing process improves dimensional accuracy and surface smoothness, enhancing both appearance and performance.

The ASTM A179 seamless steel tube is manufactured through a cold-drawn seamless process, which includes several key steps:

1. Billet Preparation: High-quality low-carbon steel billets are selected and inspected for surface defects.

2. Piercing: The billet is heated and pierced to form a hollow shell.

3. Cold Drawing: The hollow shell is repeatedly drawn over mandrels to achieve the required size, wall thickness, and precision.

4. Heat Treatment (Annealing): Tubes are annealed to relieve internal stresses and restore ductility.

5. Pickling and Cleaning: Surface oxides and scales are removed to achieve a bright, smooth finish.

6. Testing and Inspection: Each tube undergoes hydrostatic testing, eddy current testing, or ultrasonic inspection to ensure defect-free quality.

This manufacturing route results in a tube with excellent surface finish, tolerances, and mechanical consistency, meeting the stringent requirements of power plants, refineries, and industrial heat exchangers.

ASTM A179 tubes are widely used in:

· Shell-and-tube heat exchangers

· Condensers and evaporators

· Boiler feedwater heaters

· Air preheaters and pressure vessels

Their ability to handle repeated heating and cooling cycles makes them ideal for systems requiring high thermal efficiency and mechanical reliability.

In summary, the ASTM A179 seamless steel tube is a reliable and precise low-carbon steel tubing solution for thermal systems. With its carefully controlled chemical composition, excellent mechanical properties, and refined manufacturing process, it provides outstanding performance in demanding heat transfer applications. When choosing materials for condensers or heat exchangers, ASTM A179 remains one of the most trusted standards in the industry.