Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

Are you struggling with heavy structural designs and rising material costs? Finding the right balance between high strength and project efficiency is a constant headache for many project managers today. Hollow steel sections for structural use offer the perfect solution by significantly reducing material volume and self-weight without compromising strength. Their uniform geometry provides superior torsion resistance and stress distribution, making them ideal for economic, high-load designs in skyscrapers, bridges, and industrial machinery.

I remember a specific project I handled a few years ago for a port construction. We were over budget because of the sheer weight of the solid steel beams in the design. It was a logistical nightmare. When we switched the design to use hollow sections, the transport costs dropped immediately. It changed how I view materials. Let us look at why these sections are superior to traditional options.

Do you feel that traditional solid beams are eating into your budget? The hidden costs of transportation, hoisting, and painting can destroy your profit margins more quickly than you realize. Hollow sections reduce self-weight, lowering hoisting and transport costs. They place material away from the neutral axis, providing higher torsional stiffness compared to open sections like I-beams. This efficiency results in cleaner, more aesthetic designs that are easier to paint, maintain, and protect against corrosion.

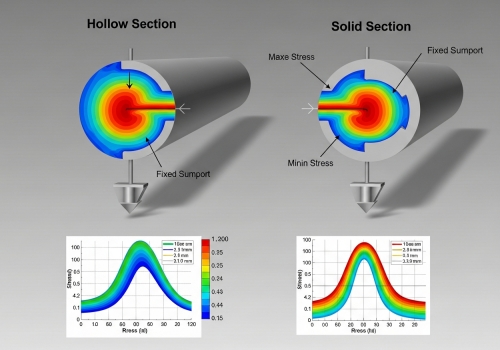

When we talk about structural integrity, the geometry of the steel matters just as much as the grade. In solid sections, a lot of the material sits near the center, or the "neutral axis." This material does very little to stop bending. Hollow steel sections for structural use remove this inefficient center. This means you get a much lighter beam that is just as strong in bending. This reduction in weight is a massive advantage for EPC companies. It means you can use smaller cranes. You can load more beams onto a single truck. For a project manager, this solves logistics problems before they happen. Furthermore, these sections handle torsion, or twisting forces, much better. Open sections like I-beams twist easily. Hollow sections are closed loops. They resist twisting very well. This is vital for bridges or cranes where loads move and change direction. Also, think about maintenance. A hollow section has a smooth, closed surface. There are no corners or gaps where dirt and water can hide. This makes painting and fireproofing much cheaper and faster. At Centerway Steel, we see many clients choose this option simply because it looks better and lasts longer in harsh environments.

| Feature | Solid/Open Sections (I-Beam) | Hollow Sections (HSS) | Benefit of HSS |

|---|---|---|---|

| Weight | Heavy | Light | Lower transport & lift costs |

| Torsion | Low resistance | High resistance | Better for multi-axis loads |

| Surface Area | High (more painting) | Low (less painting) | Lower maintenance costs |

| Aesthetics | Industrial/Cluttered | Clean/Modern | Preferred by architects |

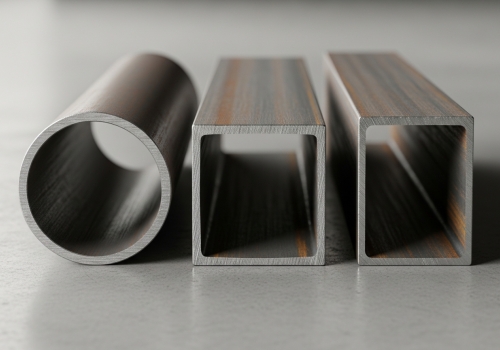

Are you confused about whether to use square, rectangular, or circular pipes? Choosing the wrong profile shape can lead to complex connection difficulties and expensive structural weaknesses later in the build. Rectangular Hollow Sections (RHS) are great for joining and welding. Square Hollow Sections (SHS) work best for columns and posts. Circular Hollow Sections (CHS) offer the highest torsion resistance and wind deflection. Selecting the right shape depends on the load direction and fabrication requirements of your specific EPC project.

At Centerway Steel, we produce and supply all three major types, and each has a specific role to play. Understanding these differences helps you buy the right product for your client. Circular Hollow Sections (CHS) These are the classic tubes. They look good and are incredibly strong. The wall thickness is uniform all the way around. This makes them perfect for resisting wind and water. You will often see them in offshore platforms or airport roofs. Because they are round, wind flows around them easily. This reduces the load on the foundation. However, joining a round pipe to a flat beam can be tricky. It often requires complex cutting. Rectangular Hollow Sections (RHS) These are the favorites for mechanical construction. They have flat sides. This makes them very easy to cut and weld. You do not need to shape the end of the connecting piece. You just cut it straight and weld it on. This saves hours of labor on site. They are very popular in frame construction and equipment manufacturing. Square Hollow Sections (SHS) These are similar to RHS but are symmetrical. They act as excellent columns. They are often called "box sections." They provide a balance between the ease of connection of a rectangle and the symmetry of a circle. However, sometimes bolting them can be difficult compared to an open beam, as you cannot easily access the inside to tighten a nut. We often advise our clients to mix these shapes. Use CHS for the main visual structure and RHS for the connecting frames. This optimizes both cost and assembly time.

| Type | Shape | Best Used For | Key Advantage |

|---|---|---|---|

| CHS | Round | Columns, Bracing, Trusses | Best aerodynamics & Torsion |

| RHS | Rectangular | Frames, Beams | Easiest to join & weld |

| SHS | Square | Posts, Columns | Good balance of strength/symmetry |

Are you worried about receiving pipes that fail inspection or crack under pressure? Inconsistent quality from unreliable suppliers can cause massive delays, safety hazards, and financial penalties on your construction site. Quality depends on strict adherence to standards like EN 10210, EN 10219, or ASTM A500. Reliable manufacturing ensures uniform wall thickness and proper seam welding. At Centerway Steel, we integrate production with rigorous ISO-certified testing to guarantee that every hollow steel section meets the specific demands of global construction projects.

I have been in this industry since 1996, and I have seen many projects fail because of poor sourcing. A "cheap" pipe becomes very expensive if it fails a third-party inspection. When you buy hollow steel sections for structural use, you must look at the standard. There are two main ways to make these: Cold Formed and Hot Finished. Cold formed sections (like EN 10219) are shaped at room temperature. They are efficient and cost-effective. They are great for most standard buildings. Hot finished sections (like EN 10210) are heated. This relieves internal stress. If your structure will face heavy fatigue—like a bridge with constant traffic or a crane—you need hot finished sections. At Centerway Steel, we take this seriously. We are an ISO 9001 company. We do not just sell pipes; we sell integrated solutions. We ensure that the weld seam is tested. We check the chemical composition. We make sure the wall thickness is consistent. We have worked with giants like CNPC and Shell. They do not accept second-best. We bring that same level of quality to every client. Whether you need large diameter SAW pipes or precise ERW sections, we manage the production and the inventory. We share China-made quality with the world.

1. Dimensional Check: Is the wall thickness uniform?

2. Tensile Testing: Will it hold the weight?

3. Impact Testing: Will it crack in the cold?

4. Weld Inspection: Is the seam solid?

Hollow steel sections for structural use provide unmatched efficiency and strength. Centerway Steel offers the expertise, variety, and quality assurance you need. Let us support your next global project.