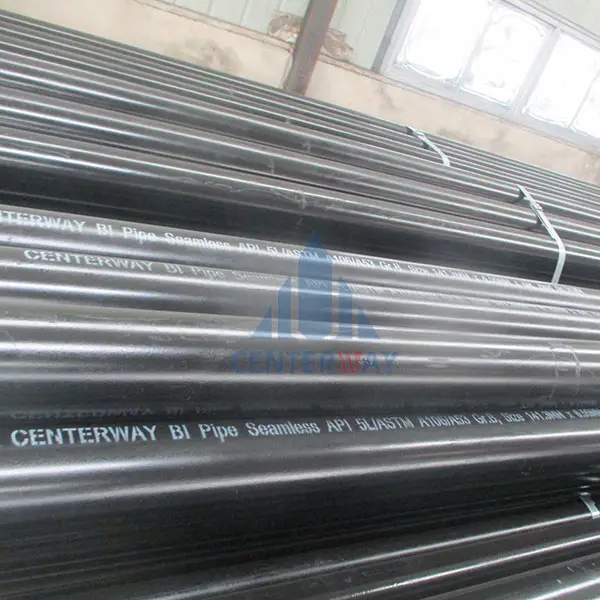

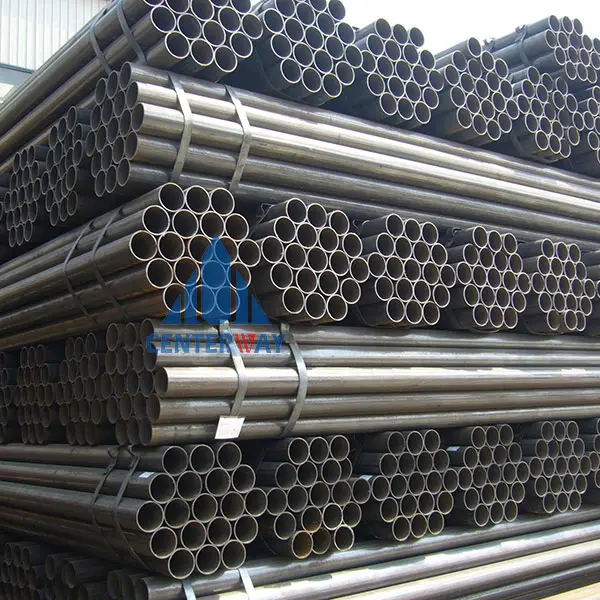

In modern industries, coated steel pipes are essential for transporting water, oil, gas, and various chemical products. However, steel is naturally prone to corrosion when exposed to moisture, chemicals, or industrial atmospheres. To enhance the durability and performance of coated steel pipes, applying a high-quality anticorrosion coating is crucial. This article provides a detailed overview of anticorrosion coatings for steel pipes, their benefits, and key requirements.

What Is Anticorrosion Coating?

An anticorrosion coating is a protective layer applied to the surface of steel pipes to prevent or slow down chemical and electrochemical reactions that cause corrosion. These coatings are designed to withstand harsh environments, including acids, alkalis, salts, and industrial wastewater. Properly applied coatings significantly extend the service life of pipelines while maintaining structural integrity.

Common Anticorrosion Coating Methods for Steel Pipes

There are several types of anticorrosion coatings commonly used in steel pipe manufacturing:

1. 3PE Coating (Three-Layer Polyethylene Coating):

This is the most widely used anticorrosion method in China and globally. The 3PE coating has three layers:

· First layer: Epoxy powder (FBE, >100 μm) for corrosion resistance

· Second layer: Adhesive layer (AD, 170–250 μm) to ensure bonding

· Third layer: Polyethylene (PE, 2.5–3.7 mm) for mechanical protection

2. IPN8710 Coating: A fusion-bonded epoxy coating with excellent chemical resistance.

3. FBE Epoxy Powder Coating: Single-layer epoxy coating, often used for internal pipe protection.

4. Coal Tar Epoxy Coating: Provides strong chemical resistance, particularly for buried pipelines.

Advantages of Anticorrosion Coated Steel Pipes

Using steel pipes with an anticorrosion coating offers multiple benefits beyond extending pipe life:

1. Combined Strength and Corrosion Resistance: The coating integrates the mechanical strength of steel with the corrosion resistance of plastics.

2. Durable External Layer: The outer layer, usually over 2.5 mm thick, resists scratches, impacts, and mechanical wear.

3. Low Internal Friction: Smooth internal surfaces reduce energy consumption in fluid transport.

4. Hygienic Standards Compliance: Coated pipes meet national health regulations for potable water.

5. Self-Cleaning Function: The smooth internal wall prevents scaling and deposits.

Key Requirements for Anticorrosion Coating

To ensure optimal protection, an anticorrosion coating must meet the following requirements:

1. Excellent Corrosion Resistance: The coating should remain stable when exposed to acids, alkalis, salts, industrial wastewater, and chemical atmospheres. It must not dissolve, swell, or chemically react with harmful byproducts.

2. Good Impermeability: The coating must prevent penetration of liquid or gas, effectively protecting the pipe surface from corrosion.

3. Strong Adhesion and Flexibility: The coating should not peel off due to vibration or minor deformation. Mechanical strength and flexibility are essential for long-term durability.

Conclusion

Investing in coated steel pipes with a reliable anticorrosion coating is essential for any industry that values safety, efficiency, and longevity. From 3PE coatings to epoxy and coal tar options, selecting the right protective layer ensures superior performance under challenging conditions. With proper application, coated steel pipes provide enhanced durability, lower maintenance costs, and safe, efficient operation for decades.

English

English Español

Español