Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

Project delays often stem from selecting the wrong materials for specific environments. You want to avoid cost overruns and safety hazards caused by improper steel grading. I will clarify the best choice for your needs. The main difference lies in the carbon content and the resulting physical properties. Mild steel is a category of carbon steel with low carbon content (0.05%-0.25%), offering high ductility and weldability. Higher carbon steels provide greater strength and hardness but become more brittle and difficult to weld.

Engineers frequently use these terms interchangeably. This causes confusion during the procurement process. I see this misunderstanding daily in my work at Centerway Steel. You need to understand the chemical nuances to make the right purchase.

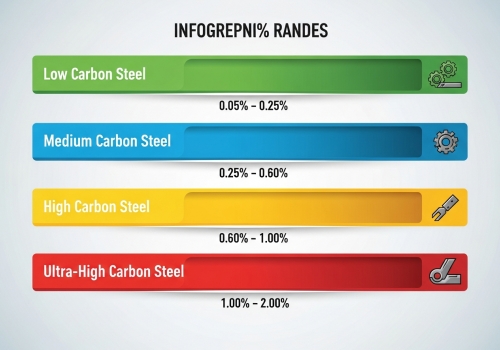

Understanding the chemical composition is the first step to ensuring project safety. You cannot afford material failure due to incorrect carbon percentages in high-stress applications. Carbon content strictly dictates the steel's classification, dividing it into low, medium, and high grades. Mild steel falls into the low category. As carbon increases, the steel becomes harder and stronger, but it loses ductility, making it harder to shape without cracking.

I define the relationship between carbon steel vs mild steel by looking at the microstructure. Steel is an alloy of iron and carbon. We add other elements like manganese or silicon, but carbon is the key player. Carbon atoms sit between the iron atoms. They stop the iron crystals from sliding past each other. This increases strength. The industry categorizes these steels based on strict percentage ranges. I have prepared a breakdown of these grades below to help you identify what you are buying.

| Steel Grade | Carbon Content (%) | Key Characteristics | Typical Applications |

|---|---|---|---|

| Mild Steel (Low Carbon) | 0.05% - 0.25% | Highly ductile, malleable, easy to weld. | Structural beams, pipelines, car bodies. |

| Medium Carbon Steel | 0.30% - 0.60% | Balanced strength and ductility. Wear-resistant. | Gears, shafts, railway tracks. |

| High Carbon Steel | 0.60% - 1.50% | Very hard, strong, but brittle. Hard to weld. | Cutting tools, high-strength springs. |

| Ultra-High Carbon Steel | 1.25% - 2.0% | Extremely hard. Can be tempered to great hardness. | Knives, punches, specialized axles. |

The way we produce steel impacts its final cost and availability. You need to know if the production method suits your project's timeline and quality requirements. Both types start with similar primary processes like the Basic Oxygen Furnace (BOF), but high carbon steels require more complex secondary processing. Manufacturers must use precise heat treatments and alloying steps to control the carbon structure, whereas mild steel is often usable in its "as-rolled" state.

The production journey for carbon steel vs mild steel begins in the same furnace. We melt iron ore and coke. We inject oxygen to reduce carbon levels. The paths diverge during the secondary refinement and finishing stages. For mild steel, the focus is on deoxidation. We remove oxygen to prevent gas pockets (porosity). We produce "killed" or "semi-killed" steel. The material is then cast and rolled. Mild steel is often sold hot-rolled. The surface might have a rough blue-grey finish. This is acceptable for structural components hidden inside walls or underground pipelines. High carbon steel demands more attention. We use an Electric Arc Furnace (EAF) to fine-tune the chemistry. The crucial difference is heat treatment.

1. Annealing: We heat the steel and cool it slowly. This relieves internal stress.

2. Normalizing: We heat it higher and air cool it. This makes the grain structure uniform.

3. Quenching: We dip hot steel into water or oil. This freezes the carbon in place. The steel becomes very hard.

4. Tempering: Quenched steel is too brittle. We heat it again slightly to bring back some toughness. Mild steel does not usually require these expensive steps. It is soft enough to machine and weld immediately. This processing difference explains why mild steel is the standard for large-scale infrastructure. It is faster to produce. It is cheaper to buy. It requires less specialized labor to install on your site.

Every project manager faces the pressure of balancing budget constraints with performance needs. You must select a material that provides long-term reliability without destroying your profit margins. Mild steel is the superior choice for construction and pipelines due to its cost-effectiveness and ease of fabrication. High carbon steel is better suited for specific tools, machinery parts, or wear-resistant surfaces where hardness is more important than ductility or weldability.

I analyze the carbon steel vs mild steel decision based on four critical factors: Strength, Cost, Weldability, and Corrosion. Strength vs. Brittleness: If your project involves high pressure or heavy loads, you might think "stronger is better." This is a mistake. High carbon steel is stronger. But it shatters under impact. A pipeline carrying pressurized gas needs to expand and contract. Mild steel yields. It stretches slightly before breaking. This property gives you a warning before a catastrophic failure. Fabrication Costs: The purchase price of the raw material is only half the story. You must calculate the fabrication cost. Mild steel is easy to cut, drill, and weld. Your workers do not need specialized certifications to weld low carbon pipes. High carbon steel cracks if welded incorrectly. You would need to heat the metal before welding and cool it slowly. This labor cost kills the budget on large projects. Corrosion Resistance: Neither material wins here. Both contain iron. Both rust when oxygen and water touch them. Mild steel pipes require coatings. We apply galvanization (zinc coating), FBE (Fusion Bonded Epoxy), or 3PE paints at our factory. Do not choose carbon steel thinking it will not rust. It will. Selection Guide:

· Choose Medium/High Carbon Steel: For axles, gears, crankshafts, and high-strength wires. Use it for moving parts, not static structures. At Centerway Steel, we supply mild steel pipes to EPC companies globally. We know that for 90% of construction needs, the flexibility and price of mild steel make it the correct engineering choice.

Mild steel offers ductility and low costs for structural and pipeline projects. High carbon steel provides hardness for wear resistance. Select the grade based on your specific welding and strength needs.