Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

You need the right steel for your project, but the options are endless. Choosing the wrong grade leads to project failure and wasted budget. I will help you choose correctly. The uses of low medium and high carbon steels depend largely on their carbon content. Low carbon steel is best for construction and pipes due to weldability. Medium carbon steel suits automotive parts requiring strength. High carbon steel is essential for cutting tools and springs because of its extreme hardness.

I know how difficult it is to find a supplier who understands these nuances. In my years of experience, I have seen many projects delayed because the purchasing team selected a material that was too hard to weld or too soft to hold weight. Let’s break down the specific characteristics of each type so you can make an informed decision for your next procurement.

You need materials that are easy to join and cheap. Rigid materials crack and cost too much. Mild steel solves this balance perfectly by being flexible yet durable. Low carbon steel contains 0.05-0.3% carbon, making it ductile and easy to weld. It is the go-to material for structural beams, pipelines, and car bodies because it does not require complex heat treatment to prevent cracking. It is often called mild steel.

I want to talk more about low carbon steel because it is the most relevant for us in the pipeline industry. You will often hear people call this "mild steel." It has a carbon content between 0.05% and 0.30%. This low amount of carbon is very important. It means the steel is not brittle. You can bend it, cut it, and shape it without it breaking. For a purchasing manager like you, the biggest benefit is the cost and the ease of use. This steel is the cheapest to produce. It is also the easiest to weld. You do not need special heating tools or complex post-weld treatments. This saves a lot of time on the construction site. At Centerway Steel, we see this material used everywhere. It is the standard for ASTM A36 structural plates and ASTM A53 pipes. If you are building a bridge, a building frame, or a water pipeline, this is the material you will use. It has a tensile strength that is good enough for carrying loads, but it is soft enough to absorb shock. It will not crack suddenly like harder steels. However, you must remember that it can rust. You will need to paint it or galvanize it to protect it.

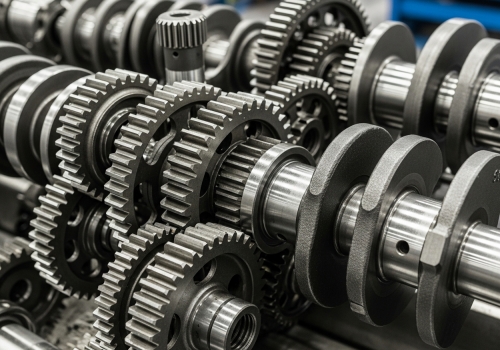

Mild steel bends under high stress. Your heavy machinery parts are failing too soon. You need a material that offers better wear resistance without being brittle. With 0.3-0.6% carbon, this steel balances ductility and strength. It is ideal for axles, gears, and shafts that endure high stress. It requires heat treatment like quenching to reach its full potential but is harder to weld than mild steel.

Now, let's move up a level. Medium carbon steel has a carbon content roughly between 0.30% and 0.60%. It also often contains manganese. This range changes the behavior of the metal significantly. It is much stronger and harder than the mild steel I mentioned before. But, there is a trade-off. Because it is harder, it is also less ductile. You cannot bend it as easily. This type of steel is very responsive to heat treatment. If you heat it and cool it down in a specific way (quenching and tempering), it becomes very tough. This makes it perfect for parts that move and grind against other parts. I often see this used in the automotive industry. Things like crankshafts, axles, gears, and railway wheels are made from medium carbon steel. However, you need to be careful with welding. If you try to weld this steel like you weld mild steel, it will crack. The heat from the welding creates a brittle zone near the weld. To fix this, your team must preheat the metal before welding and cool it down slowly afterward. This adds cost and time to the project. As a buyer, you need to know that this material requires more skilled labor to handle correctly.

Standard steel dulls quickly when cutting. Replacing tools constantly halts your production line. You require a material that stays sharp and holds its shape under extreme tension. High carbon steel holds 0.6-1.5% carbon, making it the hardest option. It is used for knives, springs, and high-strength wires. While extremely wear-resistant, it is very brittle and almost impossible to weld without cracking, limiting its structural use.

High carbon steel is the hardest of the three groups. It contains anywhere from 0.60% to 1.5% carbon. This is a very high amount. We often call this "tool steel." The carbon atoms pack tightly together with the iron. This makes the metal incredibly strong and resistant to wear. If you rub this steel against concrete, it will not scratch easily. This is why we use it for cutting tools. Knives, saw blades, drill bits, and punches are all made from high carbon steel. It is also used for springs. When you pull a high carbon steel wire, it wants to snap back to its original shape with great force. But I must warn you about the downsides. This steel is brittle. If you hit it hard with a hammer, it might shatter like glass instead of bending. It is also a nightmare to weld. In most cases, we advise against welding it at all. If you heat it up rapidly, it forms a structure called martensite, which is full of internal stress. It will crack almost immediately. For your EPC projects, you will rarely buy this for structural pipes. You will mostly buy this as finished tools or specialized equipment parts.

Memorizing every grade is impossible for a busy manager. You are mixing up applications and risking safety. This summary table clarifies everything instantly. Understanding the uses of low medium and high carbon steels ensures safety and efficiency. Low carbon is for structure, medium for moving parts, and high for cutting edges. The carbon percentage directly dictates the trade-off between weldability and hardness. To help you make the right purchasing decision, I have put together a comparison. This breaks down the uses of low medium and high carbon steels clearly. As a professional supplier, I use this logic every day when I advise my clients.

| Feature | Low Carbon Steel (Mild) | Medium Carbon Steel | High Carbon Steel |

|---|---|---|---|

| Carbon Content | 0.05% - 0.30% | 0.30% - 0.60% | 0.60% - 1.50% |

| Main Characteristic | Soft, ductile, easy to weld. | Strong, tough, moderate wear resistance. | Extremely hard, very brittle. |

| Weldability | Excellent. No preheating needed. | Fair. Needs preheating and post-heat care. | Poor. Very difficult and risky. |

| Common Uses | Pipes, beams, bridges, car bodies. | Gears, axles, shafts, bolts. | Cutting tools, springs, knives. |

| Cost | Low. | Moderate. | High. |

Carbon content defines the metal's performance. Choose low carbon for pipes, medium for machine parts, and high for tools. For the best carbon steel pipes, contact Centerway Steel today.