Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

When it comes to transporting natural gas, safety, durability, and efficiency are top priorities. Among the various piping materials available, galvanized steel pipe for natural gas stands out as one of the most reliable solutions. With its robust construction, corrosion-resistant properties, and long service life, it has become a preferred choice for residential, commercial, and industrial gas distribution systems.

In this comprehensive guide, we’ll explore:

· The advantages of using galvanized steel pipe for natural gas

· Key applications in gas distribution networks

· Installation best practices and safety considerations

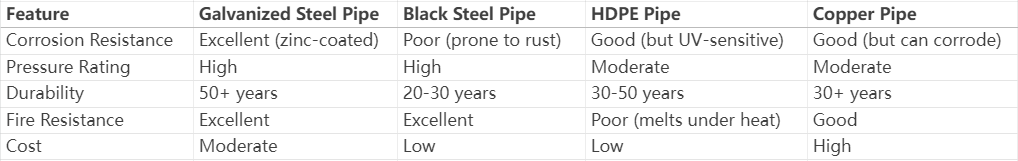

· How galvanized steel compares to alternative materials

· Industry standards and compliance requirements

Natural gas pipelines are often exposed to moisture, soil chemicals, and weather conditions that can cause rust and degradation. Galvanized steel pipe for natural gas is coated with a protective zinc layer through a hot-dip galvanization process, which significantly enhances its resistance to:

· Soil corrosion in underground installations

· Moisture-induced rust in above-ground pipelines

· Chemical reactions with natural gas components

This makes it a safer and longer-lasting option compared to non-galvanized steel or plastic pipes.

Steel pipes are known for their high tensile strength, making them capable of handling the high-pressure demands of natural gas distribution. The galvanization process does not weaken the structural integrity, ensuring that galvanized steel pipe for natural gas can withstand:

· Fluctuating gas pressures

· External impacts and heavy loads (especially in buried pipelines)

· Extreme temperature variations

Unlike plastic pipes (such as HDPE or PVC), which may degrade over time due to UV exposure or material fatigue, galvanized steel pipes have a lifespan of 50+ years with minimal maintenance. This reduces long-term replacement costs and system downtime.

Steel is inherently non-combustible, making galvanized steel pipe for natural gas a safer choice in fire-prone areas. Unlike plastic pipes, steel will not melt or release toxic fumes when exposed to high heat.

· Used for connecting gas meters to household appliances (furnaces, water heaters, stoves)

· Ideal for both indoor and outdoor installations

· Suitable for high-capacity gas distribution in factories, power plants, and commercial buildings

· Often used in compressed natural gas (CNG) stations

· The zinc coating protects against soil corrosion, making it a preferred choice for buried pipelines

· Resistant to damage from shifting soil and external pressures

· Used in areas where trenching is not feasible

· Requires additional weatherproofing in highly corrosive environments (e.g., coastal regions)

· Threaded connections: Must be sealed with gas-rated thread tape or pipe dope to prevent leaks

· Welded joints: Preferred for high-pressure systems but requires certified welders

· Flanged connections: Used in industrial applications for easy maintenance

· Use dielectric unions when connecting to copper or other metals to prevent galvanic corrosion

· Apply additional protective coatings if installed in highly corrosive environments

· All gas pipelines must undergo hydrostatic or pneumatic pressure testing before commissioning

· Soap solution or electronic gas detectors should be used to check for leaks

· Must adhere to ASME B31.8 (Gas Transmission and Distribution Piping Systems)

· Local building codes may require additional permits and inspections

Conclusion: While alternatives like HDPE and black steel are cheaper, galvanized steel pipe for natural gas offers the best balance of durability, safety, and longevity.

When selecting galvanized steel pipe for natural gas, ensure it meets:

· ASTM A53/A106: Standard specification for seamless and welded steel pipe

· API 5L: Covers line pipe used in gas transmission

· NFPA 54 (National Fuel Gas Code): Safety requirements for gas piping installations

For a safe, long-lasting, and high-performance natural gas distribution system, galvanized steel pipe for natural gas remains one of the top choices. Its corrosion resistance, strength, and compliance with industry standards make it ideal for residential, commercial, and industrial applications.

Before installation, always consult with a licensed gas piping professional to ensure compliance with local regulations and optimal system performance.