Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

When it comes to firefighting systems, reliability and durability are critical. Hot-dipped galvanized pipe has emerged as the top choice for professionals, providing unmatched corrosion resistance and long-term performance. This article explains why hot-dipped galvanized pipes outperform cheaper alternatives like welded or cold-galvanized pipes and why they are indispensable in fire safety systems.

Hot-dipped galvanized pipe is made by immersing steel pipes in molten zinc, forming a thick, uniform protective layer. This coating shields the steel from moisture, air, and corrosive substances. Unlike cold-galvanized pipes, which only have a thin electroplated zinc layer, hot-dipped pipes cover all surfaces, including internal walls and weld seams. This full coverage makes them ideal for critical applications like firefighting.

The hot-dipped galvanization process originated in the mid-18th century and has over 300 years of proven performance. Over time, it has become one of the most reliable ways to protect steel from corrosion, outlasting paint coatings, oil treatments, and cold-galvanized alternatives. Its longevity and protective capability make it the preferred method in high-stakes environments.

The thick zinc coating acts as a sacrificial layer, preventing the underlying steel from rusting. Even in humid or wet environments, hot-dipped galvanized pipe maintains its structural integrity for decades, ensuring that firefighting systems remain operational when needed most.

Because the zinc layer adheres tightly to the steel surface, it resists scratches, dents, and damage during transportation and installation. Cold-galvanized pipes and painted steel pipes are far more vulnerable to surface damage, which can compromise the pipe’s protection over time.

Hot-dipped galvanization coats both the interior and exterior of the pipe, including seams and joints. This is particularly important for firefighting pipelines, as exposed welds in cold-galvanized or welded pipes can corrode faster, increasing maintenance costs and risks.

While hot-dipped galvanized pipes may have a higher upfront cost, their longevity reduces maintenance, repair, and replacement expenses. Over the life of a firefighting system, investing in hot-dipped galvanized pipe is more economical than frequently replacing less durable alternatives.

Hot-dipped galvanized pipes are widely used in:

· Sprinkler systems – providing reliable water flow without corrosion risks

· Standpipe systems – ensuring structural integrity under high pressure

· Underground water supply lines – resisting soil-induced corrosion

· Industrial fire protection – withstanding harsh chemicals and environmental conditions

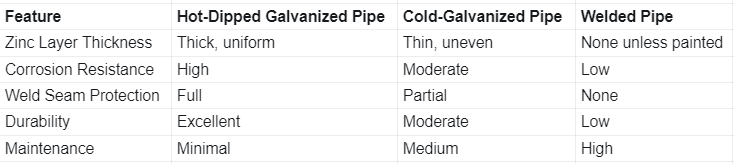

This comparison clearly shows why hot-dipped galvanized pipe is the preferred choice in critical firefighting applications.

Even though hot-dipped galvanized pipes are highly durable, proper maintenance can extend their service life:

· Inspect regularly for surface damage or scratches.

· Avoid harsh chemical cleaners that may react with zinc.

· Ensure proper installation to prevent mechanical stress.

· Apply protective coatings at connection points if exposed to extreme conditions.

For firefighting systems, using hot-dipped galvanized pipe ensures safety, reliability, and long-term performance. Its superior corrosion resistance, complete surface protection, and durability make it the industry standard. Choosing cheaper alternatives may reduce initial costs but can compromise safety and increase maintenance in the long run. When it comes to fire protection, investing in high-quality piping is a decision that pays off in both safety and cost efficiency.