What is Schedule 40 Black Steel Pipe?

Schedule 40 Black Steel Pipe is a standardized classification for steel pipe wall thickness, primarily employed in seamless or welded steel units. This designation, widely used in industries like oil and gas, ensures optimal wall thickness for various applications. It is defined by a formula considering pipe diameter and material properties.

Core Characteristics:

Material: Constructed from low-carbon steel, typically containing ≤ 0.25% carbon, such as

ASTM A53 Gr.B and Q235B.

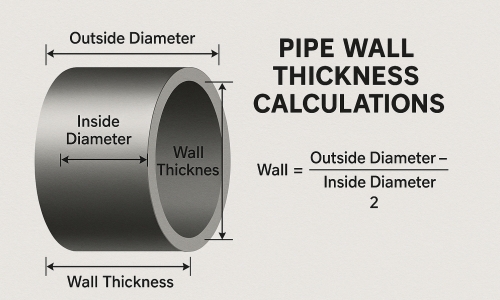

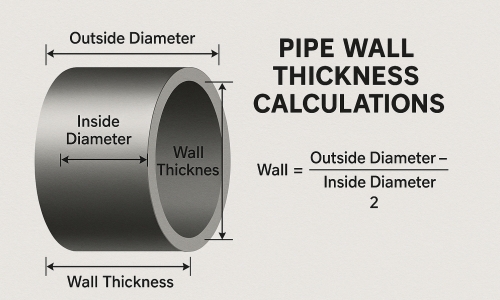

Wall Thickness: The SCH 40 represents a medium-grade thickness, providing a balance between pressure support and cost-effectiveness.

Surface Finish: Exhibits a dark gray/black appearance, maintaining a natural oxide layer post hot-rolling without any added coating.

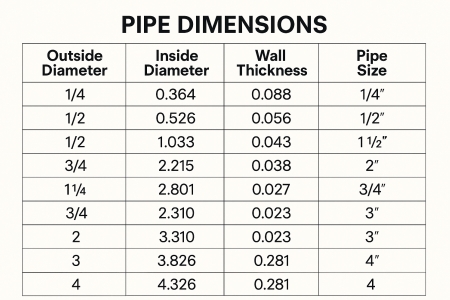

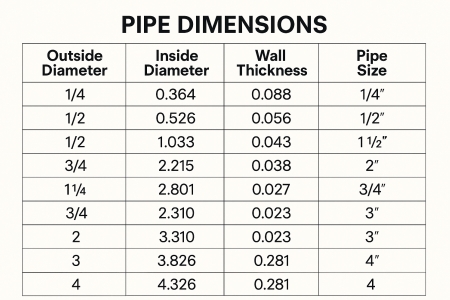

Dimensional Parameters

For precise dimensions, refer to standards like ANSI B36.10, which correlate outer diameters (OD) with specific wall thicknesses (WT). These standards aid in accurate selection based on application needs.

Key Applications of SCH 40 Black Steel Pipe

1. Construction

Scaffolding and Supports: Ideal for temporary structures due to strength and cost-effectiveness.

Ventilation Ducts: Suitable for dry indoor installations.

2. Industrial Systems

Compressed Air Lines: Efficient for low-pressure (≤0.8 MPa) systems.

Cooling Water Pipes: Requires additional corrosion protection.

3. Municipal Engineering

Temporary Drainage: Suitable for non-corrosive media conveyance.

Image Suggestion: Photos of black steel pipes in various applications (construction, industrial, etc.).

1. Cost-Effectiveness: Roughly 20%-30% cheaper than SCH 80 and 40% cheaper than galvanized pipes.

2. Ease of Processing: Low-carbon steel is easily workable for cutting and welding.

3. Reliable Strength: Suitable for most low-pressure structural needs.

Use Restrictions and Corrosion Considerations

Direct Use Limitations

Avoid use in:

Drinking water systems (due to hygiene concerns).

Acidic/alkaline media transportation.

Coastal or humid outdoor environments without protection (lifespan <3 years).

Corrosion Protection Measures

Outdoor Use: Apply an epoxy coal tar coating to extend lifespan up to 10 years.

Underground Installation: Utilize a 3PE anti-corrosion coating for enhanced durability.

Conclusion

Schedule 40 Black Steel Pipe serves as a versatile and cost-efficient solution for multiple applications, provided that appropriate corrosion measures are implemented. Essential factors for selection include pressure ratings, media characteristics, and environmental assessments.

Final Note: Always consult industry standards and environmental guidelines when choosing piping solutions to ensure long-term safety and performance.