Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

Choosing the wrong piping materials for hazardous projects creates safety risks and explodes your budget. You need a reliable, durable solution for safe gas transportation in your construction sites. Black steel pipe for gas is an uncoated mild steel pipe known for its dark iron-oxide surface. It is the industry standard for natural and propane gas lines due to its durability, heat resistance, and ability to maintain tight seals, preventing dangerous leaks better than galvanized alternatives.

Many purchasing managers struggle to distinguish between pipe types. I will explain exactly why this material is crucial for your gas lines.

You see black pipes everywhere in the industry, but do you know what lies beneath that dark surface? The dark color comes from iron oxide formed on the surface during the manufacturing process. This natural finish is specific to mild steel pipes intended for heavy-duty applications where aesthetics matter less than function. When we talk about industrial piping, the material composition is the most critical factor. Black steel pipe is made from a low-grade mild steel compound. This might sound simple, but it gives the pipe incredible strength. I have seen many projects where designers specified expensive materials when this mild steel was actually the better engineering choice. The term black steel pipe for gas is specific. It means the pipe has no protective coating like zinc or paint. This is very important. In the manufacturing process, we can make these pipes as Seamless or ERW (Electric Resistance Welded). At Centerway Steel, we have produced these pipes since 1996. We ensure they meet strict standards. The primary standards we use are ASTM A53 and ASTM A106. These standards tell you the pipe can handle pressure and heat. For gas lines, the pipe must be tough. It connects the main supply to the home or business. It also connects appliances. Because it has no coating, you can weld it easily. This creates a very strong joint. A threaded connection is also common, but welding provides a permanent seal. Below is a breakdown of the common standards we supply to our global partners:

| Standard | Grade | Manufacturing Type | Typical Application |

|---|---|---|---|

| ASTM A53 | Grade A / B | Seamless / ERW | General mechanical and pressure applications (Gas, Steam, Air). |

| ASTM A106 | Grade B | Seamless | High-temperature service, ideal for oil and gas refineries. |

| API 5L | Grade B to X70 | Seamless / Welded | Conveying gas, water, and oil in the natural gas and oil industries. |

We inspect these pipes rigorously. We check the chemical composition and the mechanical properties. This ensures that when you install a black steel pipe for gas, it performs exactly as expected. It resists heat very well. This is why you also see it in fire sprinkler systems. It can stand up to high temperatures without failing.

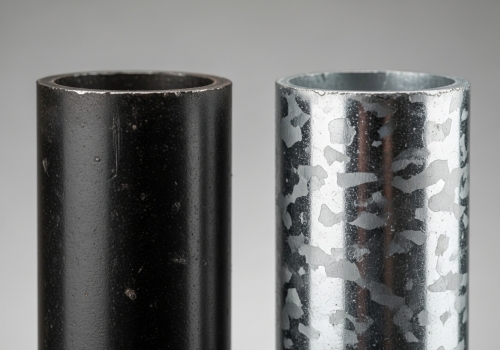

Mixing up these two common materials is a huge mistake that causes system failures and safety hazards later. You should never use galvanized pipe for gas lines. Over time, the zinc coating inside galvanized pipes flakes off, clogging regulators and burners. Black steel pipe for gas avoids this risk, offering a safer, tighter seal for combustible fluids.

I have worked with engineers who ask if they can use galvanized pipe for everything to keep inventory simple. I always tell them "no." There are four main differences you must understand. First is the coating. Galvanized pipe has a zinc layer. Black pipe does not. This zinc is the problem for gas. The gas reacts with the zinc. The zinc flakes off over time. These small flakes travel down the line. They get stuck in valves and regulators. This stops the gas flow. It can even break the equipment. Black pipe does not have this coating, so it does not have this problem. Second is corrosion resistance. Galvanized pipe is great for water. The zinc stops rust. Black pipe will rust if you leave it outside in the rain. It offers very little protection against water corrosion. However, gas is not water. Gas lines are usually closed systems or protected. So, the lack of coating is actually a benefit for the gas purity. Third is the cost. As a purchasing manager, you want to save money. Black pipe is cheaper. It costs less to make because we do not add the zinc. If you buy large quantities for a project, this price difference is huge. You save money and get the right product for the job. Fourth is the application. We use galvanized for water. We use black pipe for gas and fire sprinklers. Here is a simple guide to help your team decide:

| Feature | Black Steel Pipe | Galvanized Steel Pipe |

|---|---|---|

| Coating | Iron Oxide (None) | Zinc Coating |

| Primary Use | Gas lines, Steam, Fire Sprinklers | Water lines, Outdoor fencing |

| Cost | Lower | Higher (due to zinc process) |

| Gas Safety | Safe (No flaking) | Unsafe (Zinc flakes clog lines) |

| Rust Risk | High if exposed to water | Low (Sacrificial protection) |

Finding a supplier who balances low costs with strict international quality standards is your biggest daily challenge. To ensure quality, check for mill test reports and adherence to standards like ASTM A53. Reliable suppliers perform hydrostatic testing and provide full traceability. Always verify the wall thickness and weld strength before approving the purchase order for your project. At Centerway Steel, we know that quality is trust. We are an ISO 9001 certified company. When we produce pipes, we follow a strict process. First, we look at the pressure ratings. A standard gas line in a house might only have low pressure, maybe below 60psi. But the pipe must be able to handle much more. Good black pipe is rated for at least 150psi. Heavy-duty pipes can handle much more. We test the pipes to ensure they meet these numbers. If not installed properly, even good pipe can leak. So, the quality of the steel helps the welder make a good connection. We also focus on the "One-stop" service. In my experience, buying from many different factories is a headache. You have to coordinate shipping, check quality from different places, and handle different payment terms. We integrate production and inventory. We have pipes, fittings, and valves all in one place. This saves you time. We supply to big companies like CNPC, Shell, and Chevron. They require third-party inspections. We work with SGS, BV, and TUV regularly. They come to our factory. They check the dimensions. They check the surface. They check the markings. Here is a checklist I recommend you use when sourcing:

· Mill Test Reports (MTR): Always ask for these. They prove the chemical mix of the steel.

· Hydrostatic Test: Ensure the pipe was tested with water pressure at the mill.

· Surface Inspection: The black finish should be smooth. No deep pits or cracks.

· Dimensions: Check the Outside Diameter (OD) and Wall Thickness against the standard.

· Marking: The pipe should have the standard, size, and heat number stenciled on it. We treat every order seriously. Whether you are in Germany or the Middle East, we want to be your partner. We share our "China-made" quality with the world. We want to help you build safe projects.

Black steel pipe is essential for safe gas transport. Choosing the right partner like Centerway Steel ensures safety, compliance, and cost-efficiency for your global construction projects.