Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

You know the pressure of keeping a project on schedule. A single component failure can halt production and drain your budget. Ignoring the quality of internal components invites disaster.

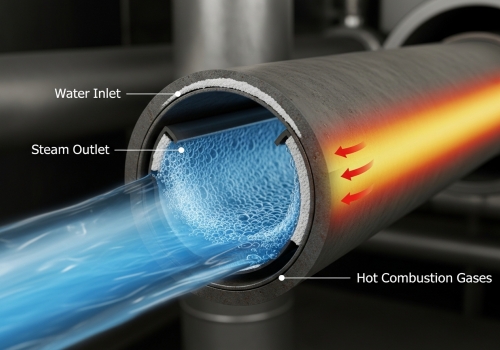

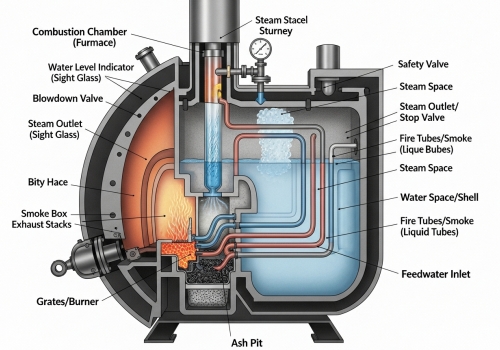

A boiler tube is a high-performance metal tube designed to transfer heat within a boiler. In watertube boilers, water flows inside; in firetube boilers, hot gas flows inside. Their primary role is converting fuel energy into steam while withstanding extreme temperature and pressure without rupturing. Understanding the definition is simple. However, selecting the right specific type for each stage of the heating process is where many projects fail.

Using a generic tube for a specific high-heat application creates a weak link. This compromises safety and shortens equipment life. You must match the tube grade to its specific zone.

A boiler is not just one bundle of pipes. It requires distinct components like economizer tubes for preheating, evaporator tubes for steam generation, and superheater tubes for high temperatures. We also use stay tubes to provide essential structural strength to the vessel. I often speak with purchasing managers who view all pipes as the same. This is a dangerous mistake in our industry. A boiler is a complex system with distinct zones. Each zone demands a specific boiler tube design to handle the thermal load. Let's break down the process flow to see why the specifications change:

· Economizer Tubes: These are the first line of defense. They capture waste heat to preheat the feedwater. This increases efficiency and saves fuel.

· Evaporator Tubes: This is the core zone. Here, phase change occurs, converting water into steam. The heat transfer rate must be high.

· Superheater Tubes: These face the harshest conditions. They raise steam temperature beyond saturation to create "dry" steam for turbines.

· Stay Tubes: These are unique. They are thicker than regular tubes. Their main job is not just heat transfer, but to hold the boiler plates together against immense pressure. At Centerway Steel, we supply materials meeting standards like ASTM A192 to ensure each zone is secure. Below is a quick reference guide for your selection process:

| Tube Type | Main Function | Key Feature | Typical Zone |

|---|---|---|---|

| Economizer | Preheat Feedwater | Efficiency Booster | Flue Gas Exit |

| Evaporator | Make Steam | High Heat Transfer | Combustion Chamber |

| Superheater | Superheat Steam | Heat Resistance | Hottest Gas Path |

| Stay Tube | Support Structure | Thick Wall | Between Sheets |

Poor heat transfer wastes fuel and increases operational costs daily. Space is also a luxury you rarely have. You need a design that maximizes output without occupying too much floor space.

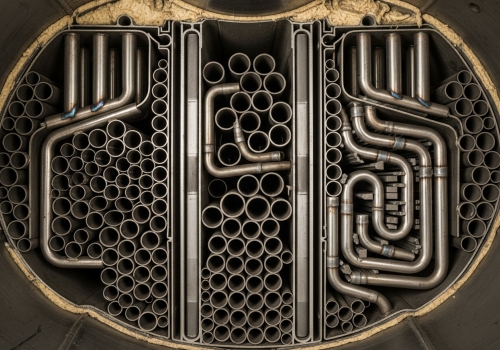

Engineers choose tube arrangements to balance heat absorption with maintenance needs. Staggered layouts increase turbulence for better heat transfer, while inline layouts allow for easier cleaning. The specific boiler tube wall thickness is also calculated based on these pressure and diameter requirements. We need to clarify a major point of confusion: the difference between a pipe and a boiler tube.

· Pipes are measured by Inside Diameter (ID). They are conduits for moving volume.

· Boiler Tubes are measured by Outside Diameter (OD). Why? Because the wall thickness is the critical safety factor against pressure. Power station boilers often operate at pressures exceeding 160 bar. A standard pipe would burst instantly. The wall thickness is your safety margin. Beyond the tube itself, how we arrange them inside the shell matters immensely. Common Arrangements:

1. Staggered Arrangement: The tubes are offset. This forces hot gas to wind through the bundle.

· Pro: High turbulence and excellent heat transfer.

· Con: Difficult to clean mechanically.

2. Inline (Grid) Arrangement: The tubes form straight lines.

· Pro: easy to shoot cleaning lances through. Ideally suited for "dirty" fuels like coal.

· Con: Less efficient heat transfer.

3. Triangular Pitch: This packs the most tubes into a circle. It is perfect for compact designs where space is tight. You must choose the layout that fits your fuel type and maintenance team capabilities.

Unexpected shutdowns are a nightmare for any EPC manager. They ruin schedules and damage your reputation. You must recognize the early warning signs before a catastrophe occurs. Failures usually stem from overheating, corrosion, or mechanical stress. Scale buildup acts as an insulator, causing the metal to overheat and rupture. Implementing a strict maintenance plan with regular inspections is the only way to ensure long-term reliability.

Overheating is the number one killer of a boiler tube. I have seen high-quality steel fail simply because of poor water chemistry. The Mechanics of Failure:

· Scale Buildup: Minerals form a hard layer inside the tube. This scale acts like a blanket. It prevents water from cooling the steel. The metal overheats, softens, and eventually bursts.

· Corrosion: Oxygen in the water attacks from the inside (pitting). Acidic flue gases attack from the outside.

· Erosion: In coal boilers, fly ash acts like a sandblaster, wearing the metal thin over time. Repair Strategies: When damage happens, you have options, but they require skill.

1. Cladding: We add weld metal to thicken worn areas.

2. Window Repair: We cut out the damaged section and weld in a new piece.

3. Plugging: We seal both ends of the tube to bypass it. Critical Warning: Never operate a boiler with more than 10% of its tubes plugged. This alters the flow dynamics and puts extra stress on the remaining tubes, leading to a cascade of failures. Sourcing seamless, high-grade tubes from Centerway Steel is your best insurance against these issues.

Reliable boiler tubes are the heart of a safe, efficient system. Understanding the types, layouts, and failure risks saves you money. Centerway Steel provides the quality you need.