Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

Procurement errors often lead to costly project delays. You struggle to find high-quality pipes that meet strict budget requirements without sacrificing performance. ERW pipe specification defines the physical and technical properties of Electric Resistance Welded pipes. It includes essential data like material grades (ASTM A53, API 5L), dimensions, wall thickness, and pressure ratings. Knowing these details helps you select the correct component for fluid transport or structural needs.

Many buyers overlook small technical details in the beginning. This oversight causes huge problems during installation or inspection. I want to help you avoid these common traps.

Choosing between different pipe seams and shapes is confusing. A wrong choice leads to structural weakness or system failure. Straight seam pipes are best for standard fluid transport and structures. Spiral welds allow for larger diameters and high pressure. You must match the pipe model and shape to your specific project load and flow requirements.

We need to dive deeper into the types of pipes available. In my years at Centerway Steel, I have seen that most people categorize welded pipes into two main groups. First, you have the Straight Seam Electric Resistance Welded pipe. We make this by passing a steel strip through rollers. The rollers bend the steel until it touches, and we weld it along the length. This creates a very uniform seam. It is perfect for water pipes, oil and gas lines, and car manufacturing. The surface is smooth, and the wall thickness is consistent. Second, there is the Spiral Welded pipe. We make this by rolling a metal strip into a spiral and welding the edges. This method allows us to make very large pipes, often bigger than 600mm. These are strong and good for high-pressure jobs like big oil transmission projects. We also need to look at the shape. The erw pipe specification is not just about round pipes.

· Round Pipe: This is the standard for moving water or gas.

· Square/Rectangular Pipe: Architects use these for building frames, furniture, and bridges.

· Special Shapes: We can make U-bends or elbows to fit tricky spaces. You must check your engineering drawings carefully. If you need high precision for a structure, square straight-seam pipes are often the best choice. If you need a long, wide water line, a spiral model might be better.

Mismatched steel grades create serious safety risks. You cannot afford a pipeline burst or a structural collapse. Material standards like ASTM A53 and API 5L determine the yield strength and chemical composition. You must select a grade that matches your operating environment. This ensures the pipe resists corrosion and withstands the necessary internal pressure.

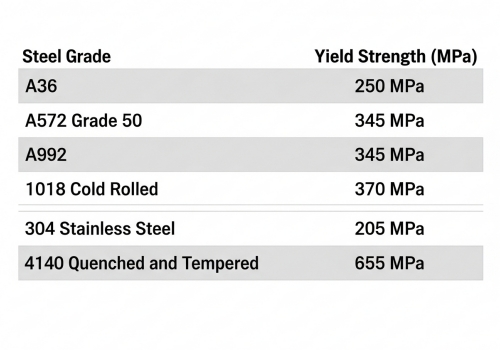

The material is the heart of the pipe. You can have the right size, but if the steel is weak, the pipe will fail. At Centerway Steel, we see orders for many different grades. The most common material for ERW pipe is carbon steel. We often use grades like ASTM A53 Grade B. This is very popular because it is reliable. It has a minimum yield strength of about 30,000 psi (or 240 MPa). It is good for welding and forming. However, your project might need something stronger. If you are in the oil and gas industry, you will likely use API 5L grades. These go from Grade B up to X42, X52, and higher. The "X" number tells you the minimum yield strength in thousands of psi. Here is a simple table to help you compare common standards I use daily:

| Standard | Common Material | Minimum Yield Strength | Typical Use |

|---|---|---|---|

| ASTM A53 Grade B | Carbon Steel | ≥ 240 MPa | Low pressure fluid, Structural |

| ASTM A252 Gr 2/3 | Carbon Steel | ≥ 310 MPa | Piling, Construction |

| API 5L Gr B - X52 | Pipeline Steel | ≥ 245–360 MPa | Oil & Gas Transmission |

| EN 10219 S235/S355 | Structural Steel | ≥ 235–355 MPa | European Construction |

You might also see stainless steel or even non-ferrous materials like copper used in specific cases. But for most industrial projects, understanding the carbon steel grade is the most critical part of the erw pipe specification. Always ask your engineer for the exact yield strength required before you buy.

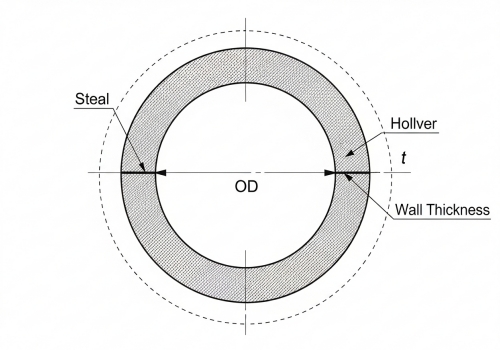

Shipping costs destroy profit margins if you calculate incorrectly. Heavy or oversized pipes create unexpected fees at the port. Dimensions range from small diameters to large 16-inch pipes. The weight depends strictly on the outer diameter and wall thickness. Calculating this precisely helps you plan logistics, manage truckloads, and control your total landed costs.

I have worked with many Purchasing Managers who forget to check the tolerances. This leads to disputes later. First, let's talk about size. ERW pipes usually range from 1/2 inch to 16 inches in diameter. We call this the Nominal Pipe Size (NPS). But you must remember that NPS is just a name. The actual Outside Diameter (OD) is a fixed number in millimeters. For example, a 6-inch pipe actually has an OD of 168.3mm. Then there is Wall Thickness. We often use "Schedule" (Sch) to describe this, like Sch40 or Sch80. But the erw pipe specification also allows for a percentage tolerance. Standards like ASTM A53 allow the wall thickness to vary by about 12.5%. You need to know this. If the wall is too thin, it might not hold the pressure. If it is too thick, you pay for extra steel you do not need. Weight is the other big factor. Since we sell steel by mass, you pay for every kilogram. You can check the weight using this formula: Weight (kg/m) = 0.02466 × (Outer Diameter − Wall Thickness) × Wall Thickness (Note: Dimensions must be in millimeters) Let’s try an example. Imagine you need a 6-inch pipe (168.3mm OD) with a wall thickness of 7.11mm. Calculation: 0.02466 × (168.3 - 7.11) × 7.11 = 28.26 kg/m. If you order 1,000 meters of this pipe, that is over 28 metric tons. If you get the math wrong, you might book the wrong shipping container. Always double-check these numbers.

Poor finishing touches stop construction on-site immediately. You hate explaining to your boss why materials were rejected. You must verify the hydrostatic test pressure, coating type, and end finishes. These final parameters confirm the pipe is leak-proof and protected against rust. Checking these details ensures the pipe is ready for immediate installation.

The job is not done when you pick the size and material. To be a true one-stop sourcing expert, you must define the finishing details. Hydrostatic Test Pressure: Every good manufacturer must test the pipe. We pump water into the pipe at high pressure to see if it leaks. The standard specification sets this pressure level. You should ask for the test report. It proves the weld seam is strong. Coatings: Steel rusts. It is a fact of nature. You need to choose the right protection based on where the pipe will sit.

· Varnish/Black Paint: Good for shipping protection, but short-term.

· 3PE (3-Layer Polyethylene): Excellent for underground pipelines.

· Galvanized: Zinc coating, great for outdoor structures to prevent rust.

· FBE (Fusion Bonded Epoxy): Common for oil and gas lines. Ends and Connections: How will your team connect the pipes?

· Plain End: Square cut. Good for socket welds or couplings.

· Beveled End: The edge is angled. This is necessary for butt welding two pipes together.

· Threaded: For screwing pipes together without welding.

· Flanged: We bolt a rim onto the end for easy assembly and disassembly. If you specify "Beveled End" in your erw pipe specification, it saves your site team hours of cutting work. If you ignore it, they waste time preparing the pipes manually. These small details show your company that you are a professional buyer who thinks ahead.

To buy the right pipe, you must define the weld type, material grade, precise dimensions, and finishing details. Mastering these specifications ensures project safety and saves money.