Sharing China-Made with Global Customers

Sharing China-Made with Global Customers

Choosing the wrong piping material leads to catastrophic project delays and budget overruns. You need to know the specific strengths of your materials to ensure safety and longevity in your infrastructure. Galvanized pipe generally offers superior durability against rust due to its zinc coating, making it "stronger" in corrosive environments. However, black iron pipe is the standard for gas lines. To determine what is stronger black iron pipe or galvanized pipe, you must first define the environment: wet or dry.

Many clients ask me about the specific mechanical differences between these two common materials. Let’s break down the technical details so you can make the right purchase for your EPC company.

Corrosion is the biggest enemy of pipeline longevity in any construction project. The main difference lies in how these two pipes handle exposure to oxygen and water over time. Galvanized pipes feature a protective zinc layer that acts as a sacrificial barrier against rust. Black iron pipes are made of mild steel with a dark iron oxide coating, offering minimal protection against moisture.

When we discuss what is stronger black iron pipe or galvanized pipe regarding corrosion, galvanized wins easily. At Centerway Steel, we see this daily. Black iron pipe is essentially mild steel. It has a small amount of carbon. This makes it strong under pressure, but it has a weakness. It rusts very fast if it touches water. The dark color comes from iron oxide formed during manufacturing. This oxide provides a tiny bit of protection, but not enough for outdoor use. Galvanized pipe is different. It starts as steel, just like black iron. But then, we coat it in zinc. This process is called galvanization. The zinc acts as a shield. It fights the rust so the steel inside does not have to. This stops mineral deposits from building up inside the pipe. If you are building a water line, those deposits are dangerous. They can clog the flow. For structural strength against elements, the zinc coating makes the galvanized pipe much more durable for the long term. Here is a quick comparison of their resistance properties:

| Feature | Black Iron Pipe | Galvanized Pipe |

|---|---|---|

| Primary Material | Mild Steel | Steel with Zinc Coating |

| Coating | Iron Oxide (Dark Grey) | Zinc (Silver/White) |

| Water Resistance | Low (Prone to rust) | High (Resists rust) |

| Gas Tightness | Excellent | Good (But flakes can clog) |

| Typical Life Span | 10-15 Years (if exposed) | 40-50 Years |

The way a pipe is made dictates where you can safely install it. Understanding the production line helps you justify your purchasing decisions to your engineering team. Black iron pipes are often seamless or welded, meant for gas transport. Galvanized pipes go through a hot-dip zinc bath, making them ideal for water transport and outdoor structural applications.

At Centerway Steel, we manage the supply chain for both types. The manufacturing process changes the physical properties. Black iron pipes are formed by stretching steel into a seamless tube. Sometimes, we force the edges together and seal them with a weld. This creates a very tight seal. This seal is why black iron is the king of gas transport. Natural gas and propane molecules are small. They need a perfect container. Black iron provides this. It is also more fire-resistant. This is why you see it in fire sprinkler systems. Galvanized pipes take an extra step. We take the steel strip and pass it through hot molten zinc. The temperature is very high, around 820 to 860 degrees Fahrenheit. The zinc bonds to the steel. Then, we cool it down in a quench tank. This locks the coating in place. However, this coating can flake off over time. If this happens inside a gas line, the flakes clog the regulators. That is a disaster. But for water, fences, and outdoor railings, this coating is perfect. When you ask what is stronger black iron pipe or galvanized pipe, you must look at the application:

· Black Iron: Best for natural gas, propane, steam, and fire sprinkler systems.

· Galvanized: Best for water supply lines, outdoor heavy construction, scaffolding, and fence posts.

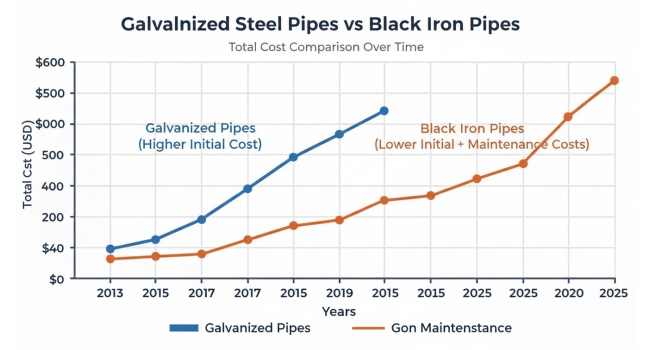

Budget is always a primary concern for a purchasing manager. You need to balance the upfront material cost with the long-term maintenance costs of the facility. Galvanized pipes are more expensive due to the added zinc coating process. Black iron pipes are cheaper upfront but may cost more long-term if used incorrectly due to corrosion maintenance.

I have worked with many EPC companies in Europe. I know you need to save money without losing quality. Black iron pipes are generally cheaper. This is simple logic. They require less processing. We do not have to buy zinc or run the galvanizing bath. If your project is strictly for gas lines or indoor oil transport, black iron is the smart financial choice. You save money, and the pipe does exactly what it needs to do. However, do not let the lower price tag fool you for other projects. If you use black iron outside, you will pay more later. It will rust. You will have to paint it, repair it, or replace it. Galvanized pipe costs more at the start. The zinc coating adds to the manufacturing bill. But, it lasts 40 or 50 years with almost no maintenance. It resists scratches and abrasions. The zinc takes the damage, not the steel. So, is it worth it? Yes, if you are dealing with water or weather. The "strength" of the investment is higher with galvanized pipe in these cases. We at Centerway Steel can help you analyze your total project cost. We supply both types to Fortune 500 companies. We can bundle your order to get the best price for both materials.

Galvanized pipe resists corrosion better for water and outdoor use, while black iron is stronger for gas seals. Contact Centerway Steel for a one-stop solution for your piping needs.