Pragmatism, Integrity, Passion

Pragmatism, Integrity, Passion

Pipe failures on a construction site can ruin a project's timeline and budget. You cannot afford weak connections when thousands of dollars are on the line. Here is the expert guide to welding carbon steel pipes correctly. Learning how to weld carbon steel pipe involves selecting the right method—usually SMAW for field work or GMAW for shop efficiency. Key steps include cleaning surfaces, selecting matching filler metals, and controlling heat input to prevent cracking and ensure the pipeline's integrity.

I have seen many projects suffer because the engineering team did not pick the right welding procedure. This leads to leaks, failed pressure tests, and expensive repairs. Let’s look at the details so you can avoid these problems.

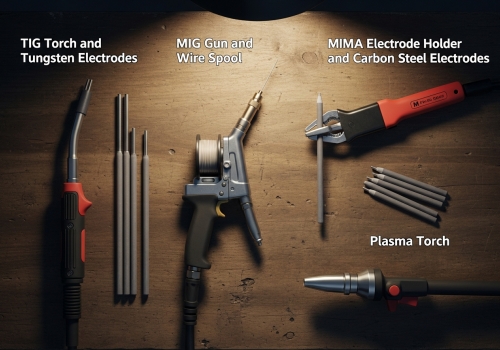

Choosing the wrong method kills efficiency and increases defect rates. You do not want to waste labor hours on a technique that is too slow for your schedule. Here are the four standard techniques used in the industry today. The most common methods are Manual Arc Welding (SMAW) for versatility, Gas Metal Arc Welding (GMAW) for speed, and Submerged Arc Welding (SAW) for thick pipes. Each has specific strengths depending on the pipe diameter and the location of the work.

As a supplier who has been in this industry since 1996, I see different methods used for different needs. When you ask how to weld carbon steel pipe, the answer depends heavily on where the welding happens. Is it in a controlled factory setting or out in the harsh environment of the field? Let's break down the methods we see most often at Centerway Steel and on our client sites.

This is what we call "stick welding." It is very common. The welder uses a handheld electrode. It is excellent for field work because wind does not affect it much. However, it is slow because the welder has to stop frequently to change electrodes. It relies heavily on the skill of the worker to maintain a steady hand.

This is an automatic or semi-automatic process. It uses a wire feeder and a shielding gas. It is much faster than stick welding. In our factories, we use this for standard pipe fittings. It creates a clean weld with little slag. The downside is that you need to protect the work area from wind, so it is better for indoor shops.

This is crucial for the large diameter pipes we produce. The arc is hidden under a layer of granular flux powder. It allows for very high deposition rates and deep penetration. It is perfect for thick walls and long straight seams, like those used in oil and gas transmission lines.

For high precision, we use Plasma or TIG (GTAW). This is often used for the "root pass"—the very first layer of the weld inside the pipe. It ensures there are no bumps inside the pipe that could stop the flow of oil or gas. Here is a simple comparison table to help you decide:

| Method | Best Use Case | Speed | Skill Level Needed |

|---|---|---|---|

| SMAW (Stick) | Outdoor construction sites, repairs | Slow | High |

| GMAW (MIG) | Indoor fabrication shops | Fast | Medium |

| SAW (Submerged) | Manufacturing heavy/thick pipes | Very Fast | Medium (Machine Operator) |

| GTAW (TIG) | Root passes, high precision | Slow | Very High |

A dirty pipe leads to weak joints and failed inspections. Weak joints fail under high pressure and can cause safety hazards. You must prep the surface correctly to get a good result. Proper preparation requires removing rust, oil, and paint from the pipe ends. You must also bevel the edges to the correct angle. This ensures the weld penetrates deep into the steel and creates a strong bond between the sections.

In my 20+ years of experience, I have found that 80% of welding defects happen because of poor preparation. It does not matter how good your welder is. If the pipe is dirty, the weld will fail. When customers ask us how to weld carbon steel pipe so it passes X-ray inspection, I tell them to look at their cleaning process first.

Carbon steel rusts naturally. It also comes with oil or varnish from the factory to protect it during shipping. You must remove this completely.

· Grinding: You need to grind the metal until it is shiny and bright. Do this for at least one inch (25mm) back from the edge.

· Chemical Cleaning: If there is oil or grease, use a solvent. If you weld over oil, it turns into gas bubbles inside the weld. This causes porosity (tiny holes).

You cannot just butt two flat pipes together. The weld will not go all the way through the wall thickness. You need to cut an angle on the edge. Usually, this is a 37.5-degree angle. When two pipes meet, they form a "V" shape. This allows the welder to fill the joint from the bottom up, ensuring a solid connection.

The pipes must line up perfectly. We use internal or external clamps to hold them. If one pipe is higher than the other (Hi-Lo misalignment), the weld will have a weak spot and stress will build up there. Here is a checklist for your site supervisors:

| Preparation Step | Why it is important | Consequence if skipped |

|---|---|---|

| Remove Rust/Paint | Ensures electrical contact and purity | Inclusions in the weld |

| Remove Oil | Prevents hydrogen and gas pockets | Porosity (holes) |

| Beveling | Allows full penetration | Weak joint center |

| Clamping | Keeps pipes straight | Misalignment and stress |

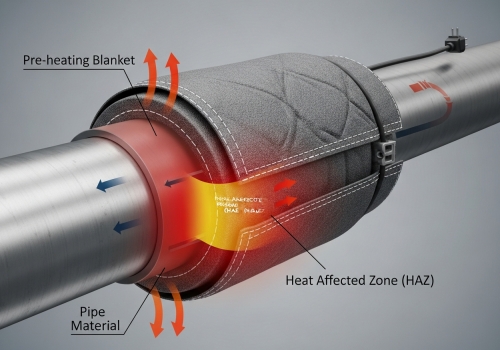

Cracks are a welder's nightmare and cost a lot to fix. Repairs destroy your project budget and delay the completion date. You need to control the heat input to stop them from happening. Preventing thermal cracking involves preheating the steel to slow down the cooling rate. You must also select low-hydrogen electrodes and maintain stable voltage parameters. This avoids high stress in the heat-affected zone where the pipe is most vulnerable.

Carbon steel is generally easy to weld compared to alloy steels, but it still has risks. The biggest risk is thermal cracking. This happens when the metal gets hot and then cools down too fast. The metal shrinks and pulls apart.

When we talk about how to weld carbon steel pipe safely, we focus on parameters.

· Current and Voltage: If the current is too high, you burn through the pipe. If it is too low, the weld does not stick (lack of fusion). You must follow the WPS (Welding Procedure Specification) strictly.

· Travel Speed: Moving the torch too fast makes a thin, weak weld. Moving too slow dumps too much heat into the pipe, which changes the steel structure and makes it brittle.

For MIG/MAG welding, gas is critical. It protects the liquid metal from the air.

· CO2: Cheap and gives deep penetration. But it causes a lot of spatter.

· Argon/CO2 Mix: Smoother arc and less spatter. It looks better but costs more. For our high-end EPC clients, we usually recommend the mixture to ensure the weld looks good and holds strong.

To stop cracks:

1. Preheat: For thick pipes, we heat the steel before welding. This reduces the shock of the hot arc.

2. Pass Sequence: Do not try to fill a large gap in one go. Use multiple thin layers (passes).

3. Stress Relief: Sometimes, after welding, we wrap the pipe in heating blankets. This is called Post Weld Heat Treatment (PWHT). It relaxes the metal stresses. Here is how we categorize common defects:

| Defect | Main Cause | Simple Solution |

|---|---|---|

| Thermal Cracking | Cooling too fast | Preheat the pipe |

| Porosity | Wet electrodes or no gas | Dry the rod / Check gas flow |

| Undercut | Current too high | Turn down the amps |

| Slag Inclusion | Poor cleaning between passes | Chip and brush every layer |

To weld carbon steel pipe successfully, you must choose the right method (SMAW or GMAW), clean the metal thoroughly, and control your heat settings. Quality preparation prevents costly failures.